现代汽车线束的主要部件

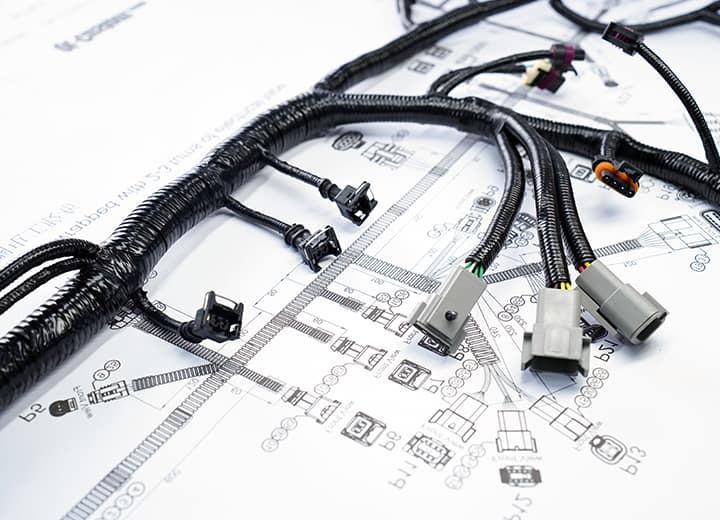

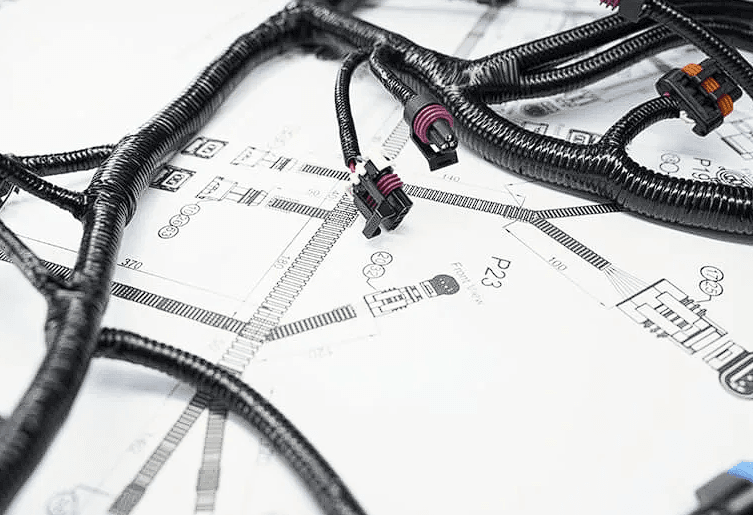

Automotive Wire Harness is a vital part of the vehicle system. Without this the vehicle system will not run. These harnesses also need many kinds of components. With the proper kinds of parts the harness will provide top quality services. So before selecting a harness checking the components is necessary. QL-Custom Technology Ltd. is a company that makes these essential Automotive Wire Harnesses. They are very good at it and have many years of experience. Their team works with care and knows how to make strong, safe, and smart wire harnesses. They ship their parts to many places around the world. If you are looking for a trusted team that makes top-quality harnesses, QL-Custom is the right choice. Essential Parts of a Automotive Wire Harness Wires and Cables Wires are like tiny roads inside the car. They move power and messages from one part to another. Most wires are made from copper. Copper is strong and safe. It carries power well. Some cables may use other light metals. Every wire has a cover made of plastic or rubber. This cover keeps the wire safe from damage, heat, and water. Good wires need to bend and twist without breaking. This helps them fit in small and tight spaces inside the car. QL-Custom only uses strong, flexible cables that are tested before use. Their vehicle harness can work in both very hot and icy places. These wires last a long time and stay safe in tough spots. Connectors Connectors are small but very important. They join the wires to the car's different parts. Some connectors go to the engine, some to the lights, and some to sensors. They help the wires send the right signals to each part. Some connectors are tiny, and some are large. Some are made to...

阅读更多 "汽车线束随着时间的推移发生了哪些变化

Cars use Automotive Wire Harnesses to move power from one place to another. This power helps make lights shine, engines run, radios play, and many more things work. We call these wires a wire harness when they are put together safely and tidily. A wire harness keeps everything working smoothly and safely. It stops wires from getting messy or breaking. It also makes it easier to fix or change things later. Every part of your car that needs power or talks to another part uses a wire harness to work. QL-Custom Technology Ltd. is very good at making these wire harnesses. Our team is competent, skilled, and always follows safety rules. We use new tools and machines to make our products even better. We send our harnesses to many parts of the world. Our harnesses are used in cars, robots, hospital machines, cameras, and more. We constantly check our work to ensure it is strong, safe, and lasts long. People trust us because we care a lot about doing a good job. How Automotive Wire Harness Began in Cars In the past, cars were much simpler. They had very few parts that needed power. The wires were thick and had no colors. There were no labels or tags to help. This made it hard to fix things when wires broke or got mixed up. People often had to guess which wire did what. Each car company used different kinds of Automotive Wire Harnesses. This meant it was not easy to make or repair cars. But cars did not have many extra features, so this was okay for a while. As more things like radios, air conditioning, and safety lights were added, cars needed better wires and better ways to organize them. Automotive Wire Harnesses Got Better As cars grew...

阅读更多 "Design a Custom Wire Harness for Specific Needs

A Custom Wire Harness is a group of wires tied together to send power or information from one part of a machine to another. These wires are placed together neatly to stay safe and easily handled. The harness also includes other vital parts like connectors, coverings, and clips that hold the cables in place and stop them from moving or breaking. It's called ‘Custom Wire Harness’ because it is made for a special purpose. It is built to match your exact needs. Every wire is put in the right place for your machine or project. That means no extra wires getting in the way and no missing wires either. It keeps things clean, helps your machine work better, and ensures it lasts longer. A strong and safe electrical harness can help everything if you're building a robot or working with electronics correctly. A good engine wiring harness is essential for people who fix or build cars because cars move a lot and get hot. Some machines also work in water or dirt, while others must stay clean. A custom wiring harness works in all of these situations because it's made to fit the job. Why Use a Custom Wire Harness All machines and tools are different. Some are small and simple. Others are large and have lots of moving parts. Some tools get hot, some get cold, and others may get wet or dusty. A regular wiring harness might not work well for every situation. That is why a custom wiring harness is the best choice. It is built to do the job right from the beginning. [caption id="attachment_8054" align="alignnone" width="300"] Wire Harness[/caption] With a custom harness, you get the right shape and size for your tool. The wires stay safe and don't move around too much. The whole thing...

阅读更多 "Certifications for Automotive Wire Harness Components

Cars need lots of wires to run the right way. These wires are not just lying around. They are grouped together in special bundles, and these bundles are called Automotive Wire Harnesses. An Automotive Wire Harness helps send power and messages from one part of the car to another. It works like the car's nervous system. It allows the engine to start, makes the headlights and tail lights turn on, powers the radio and sound system, helps the dashboard show the speed, and even runs safety tools like airbags and seat belt alarms. The car might not work right if the auto electrical wiring harness is not made well. Sometimes, if one wire is broken, the whole car might stop. It could even stop in the middle of the road. That is very dangerous. So, it is important that these wires are made safely. They must be tested many times to ensure they will not break. Company with Certifications for Automotive Wire Harnesses Some tests check if the wire can stand heat or cold. And others check if it is safe from fire or electric shocks. Big safety groups run these tests. They make sure all the wires are clean, secure, and strong. If an electrical harness has a badge, you know it passed the test. QL-Custom Technology Ltd. is a company that makes these wire harnesses. They are really good at it. They use strong and clean parts to build wires that last a long time. They test every wire to make sure it works right. Their wires are used in many places around the world. Many people and big companies trust them because they always make safe, high-quality products. Why Certifications Matter Certifications are like gold stars or badges. They show that something was made correctly...

阅读更多 "Custom Wire Harness: Customize for Harsh Environments

Not all places are easy for machines. Some areas are very hot. Some are very cold. Some are wet or dusty. Machines in these places still need wires that work all the time. If the wires break, the machine will stop. This is why people make special wire harnesses for hard places. These are called custom wire harnesses. You can pick strong wires that do not snap or melt. You can choose thick covers that stop water or dirt from getting in. There are even covers that stop fire. Special seals can also close up the ends so nothing can get inside. These things help the harness stay safe and strong, even in the worst places. But not all places are easy for machines. Some areas are very hot or cold. Some have a lot of dust or water. These kinds of places are called harsh environments. Regular wires might not last long or even stop working in these places. Custom wire harnesses are suitable for these places. QL-Custom Technology Ltd. is a company that makes these strong and safe harnesses. They offer the best and high quality products. People from many countries trust their parts. They make high-quality products that help machines last longer and stay safe. Harsh Environment for Custom Wire Harness A harsh environment is any place where machines face tough conditions. It could be very hot, like inside a car engine. It could be very cold, like outside in the snow. Some places have water, rain, or chemicals that can hurt wires. Other places might have dust, dirt, or strong shaking from moving parts. In these tough places, standard wires can break or stop working. That can be dangerous and cost a lot of money to fix. Machines may not work right, and...

阅读更多 "用于高质量定制线束的材料

A Custom Wire Harness is a customized group of wires tied and wrapped together. These Custom Wire Harnesses are used to send power and signals to machines. They are essential. You can see Custom Wire Harnesses in cars, airplanes, and many big tools and machines. The wires inside the harness must be strong. They must be safe, too. A wire breaks or gets too hot can stop a machine. It can even be dangerous. That is why people use special parts to make good harnesses. The better the parts, the better the harness. Explore and find out all about the parts that make wire harnesses work well. You will learn about the wires, the covers, the clips, and other parts. Each part helps the harness do its job and last a long time. A Company You Can Count On QL-Custom Technology Ltd. is a company that people all over the world trust. We are known for building strong, safe, long-lasting Custom Wire Harnesses systems and overmolding cable assemblies. Our team works very hard daily to ensure everything we create is done correctly. We use innovative tools and strong machines and follow good steps to check every wire and every part. Our workers are competent and friendly and trained to do things with care. We already have a big quality certificate called ISO9001:2015 and are working hard to do more good. Our team is very good at building all kinds of custom wire harness wiring systems that people need. We have helped with small and big jobs and always try to give the best results. When you work with us, we listen closely to what you want. We talk with you to plan everything and provide ideas to improve your project. From start to finish, we make sure you are...

阅读更多 "Top Best Automotive Wiring Harness Company

Cars today have many wires inside. These wires help things like lights, buttons, radios, and the engine work right. The Automotive Wiring Harness carries power from one part to another. They also carry messages that tell the car what to do. Without these wires, the car would not work at all. So, having strong and smart cables in the car is very important. QL-Custom Technology Ltd. is the best provider for wire harness. They are very experienced harness manufacturers. This company makes sure that all their products are good quality. They Work very hard to satisfy you with your products. QL-Custom Technology Ltd. has an expert team that always tries something new to get updated. What Makes a Great Automotive Wiring Harness A good harness wiring should be robust. It should not melt or break, even in hot or cold places. It should be safe from water and dirt. The wires must be clean and made just right to fit your car's needs. Each wire is covered with strong plastic to keep out dirt and water. The plugs at the ends must fit tight and not come loose. An innovative design saves time and money during building. At QL-Custom, they test each wire harness many times to ensure it is just right before sending it to the customer. They want it to work well right away. Why Choose QL-Custom Technology Ltd. QL-Custom Technology Ltd. Is the exact company for producing the best and exact automotive wiring harness. They make the best items by following ISO9001:2015. They also obey the IATF16949 rules. They try their best to improve their product by following the rules. They only use the best materials to make parts. Their workers are trained and careful. They use innovative tools that help build parts fast and...

阅读更多 "Custom Car Wire Harness Manufacturer

Seeking strong, safe, and long-lasting Custom Car Wire Harness? QL-Custom Technology Ltd. makes special custom car wire harnesses that fit every need. High-quality wires help cars run smoothly, ensuring they work well for a long time. Every wire is made with great care and attention. The goal is to give the best wires that are safe, powerful, and built to last. A car needs good wires to work the right way. A lousy wire setup can cause serious issues. Wires connect many essential car parts. If the cables are not correct, the car might not start. Lights may stop working. The battery could lose power quickly. This is why a good wire setup is so vital. It makes sure power flows the right way. It also protects against electrical failures. It keeps the car safe and working at its best. Why Choose Automotive Wire Harnesses Works Better & Lasts Longer A custom wire setup makes the car run better and last longer. Automotive wiring harness issues can lead to big trouble. Weak wires may cause short circuits or even engine failure. A strong custom car wire harness is designed to stop these issues before they happen. It is built to handle heat, shaking, and harsh conditions. These wires will stay strong and work right regardless of the road or weather. Made Just for Your Car Every car is different. A custom-made wire setup fits perfectly. It connects all parts in the best way. A perfect fit means easier installation and better performance. A car’s electrical system must match its wiring exactly. A custom harness keeps the setup clean, without extra wires or messy links. Everything is placed in the right spot to ensure the car works at its best. Best Parts & Materials Only top-quality wires, covers, and connectors...

阅读更多 "Difference Between Cable Assemblies and Wire Harnesses

Wires carry power. They must be safe and organized. A wire harness holds wires together. It keeps them neat. Cable assemblies do the same but adds protection. It has a strong outer layer. This layer guards against heat, water, and damage. Wire harnesses are best for keeping wires in place. Cable harness assembly works well in harsh conditions. Cable Assemblies: the basics It covers a group of wires in a hard cover. It keeps the wire safe from many things. In bad conditions it keeps the wires safe. There are many sizes available. You can also find many shapes of it. The cover is very hard; it is made of plastic or rubber. This cover helps wire to last long in harsh weather. Industries need these because these make the wire safe. These places include hospitals, construction sites, and power plants. Wires in these places must stay safe from bad weather, heavy movement, and chemicals. It makes sure they stay working for a long time. It helps machines to work properly. What is Wire Harness? It brings all the wires together. It does not have any hard covers. Instead, it has a light cover to keep the wires neat and in place. Wire harnesses are found inside cars, TVs, and household machines. They work best in clean and dry places. A wire harness helps wires stay in the right place. It stops the wires from getting mixed. Loose wire can cause problems. It keeps the wires together and in a good position. With a wire harness you can easily find a wire when you need it. These are not so costly. Wire harnesses are used in many places. These devices need well-organized wires but do not need heavy protection. Key Differences Between Assemblies & Harnesses Protection: Cable-assemblies...

阅读更多 "Maximum quality Automotive-wire-harness at ease

An automotive wire harness is like a bunch of tiny ropes that carry power and signals to different parts of the car. It helps turn on the lights, run the engine, play music on the radio, and blow cold air on hot days! Without it, the wires would be all messy, and the car would stop working. The harness keeps everything neat so the car can work properly. It is important because it keeps the car's wires safe. If the cables get tangled, they can break, and things in the car might stop working! The lights might not turn on, the radio might be silent, or the vehicle might not start! The harness keeps everything in place so the car can work safely daily. It also stops wires from rubbing together and wearing out too fast. Think of it like a superhero keeping the cables safe! QL-Custom makes special wiring harnesses! These wires help cars, trucks, and big machines move and work. Machines need wires to run, and we make sure the cables are safe and strong. If machines do not have good wires, they stop working. But with QL-Custom, everything works great! We use small parts and big parts. We put all the cables in the right place. We make them strong so they do not break. We help people get the right wires. We take time to make sure everything is just right! Parts of an automotive-wire-harness kit A wire harness kit has many small parts that help it work. Each part has a big job to do: Wires are like tiny roads that carry power to different car parts. Connectors – These help wires join so electricity can move from one place to another. Covers – These wrap around wires like a blanket to keep them safe...

阅读更多 "