Low pressure Molding could protect LED strip, PCB and magnetic very well. Macromelt & Technomelt as a common molding materials play in an encapsulating and environmentally protection on sensitive electronic components, IC molding sealing, Magnetic over molding and other sensitive components pakage.

The main intention is to protect the sensitive electronic components during the molding stress, because high pressure molding would harm the properties of these components.

Additionally, Low Pressure Molding seal molding also protects electronic components against dust, moisture and vibration stress. It is also commonly used for Cable relief and sealing connectors.

>> Technomelt & Macromelt resins

The low pressure resins including PA (Polyamide), PO (Polyolefin) and PUR Hotmelt . Key components of the process are specialized molding equipment and raw materials. Dimer acid-based macromelt materials, (also referred to as hotmelt) are what acts as molding materials. The materials become less vicious when heated and they can be re-shaped and later harden to attain the desired form when cooled. Compared to other materials, this macromelts are particularly suited for low pressure molding because of two main reasons

- Low-viscosity during processing at low temperature which requires low injection pressure, a very important property when it comes to over-molding sensitive electronic components.

- High performance adhesive property, which is purely mechanical with no chemical reaction involved.

Know more about the Low Pressure Molding please go to Our Blog .

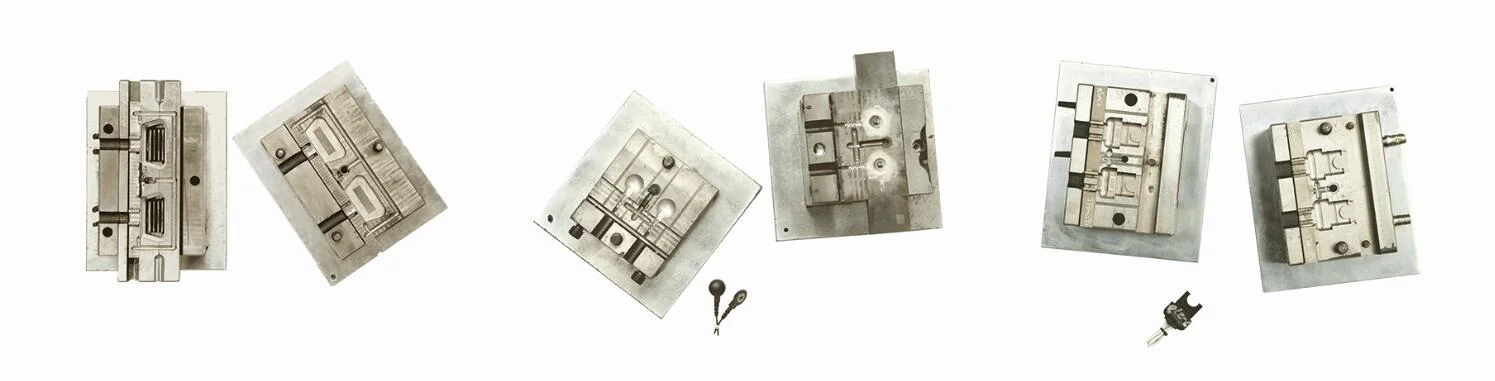

>> Custom Mold Tooling Service

>> Benefits

Protect the sensitive components

- Effectively seal the components of the package, moisture, water, dust, chemical resistance of the role. In addition, both can withstand both high and low temperature, impact resistance, insulation and flame resistance, including performance.

- Traditional injection molding processes are flawed due to high pressure due to low pressure molding requiring only a small amount of pressure to allow the melt to flow into a small mold space, thus not damaging the fragile components that need to be encapsulated, to a significant extent The scrap rate.

Saving total production costs

- Low-pressure injection molding process equipment costs low. Conventional injection molding process equipment systems, in general, are costly, including the purchase of high pressure injection molding machines, as well as water cooling systems and expensive steel molds. The low-pressure injection molding process equipment system is generally relatively simple, only by the hot melt machine, work console and mold three parts.

- Due to the very low injection pressure, the mold can be cast aluminum mold, easy to mold design, development and processing, can save material costs and development cycle. Such as the use of low-pressure injection molding process to replace the traditional potting process, you can also save the potting of the shell and after heating and curing costs.

- Low pressure and low temperature can greatly reduce the finished product waste scrap rate, to avoid unnecessary waste. Therefore, the choice of low-pressure injection molding process can not only greatly improve the production efficiency and reduce the defective product yield, but also from the overall help to create a cost advantage.

Shorten the product development cycle

- Low-pressure molding die can be cast aluminum mold, rather than steel, it is very easy to mold design, development and processing, can shorten the development cycle. In addition, compared to time-consuming two-component potting process, low-pressure hot melt injection molding process cycle can be reduced to a few seconds to several tens of seconds, greatly promoted the production efficiency.

>> Low Pressure Molding Machine

The low-pressure molding process is a process in which the encapsulating material is injected into the mold at a very low injection pressure (2-20 bar) Fast curing molding (5 ~ 50 seconds) of the packaging process to achieve insulation, temperature, shock, vibration, moisture, water, dust, chemical resistance and other effects. Low-pressure molding is a process between high-pressure injection molding and potting.