Design Considerations for Custom Low Pressure Molding

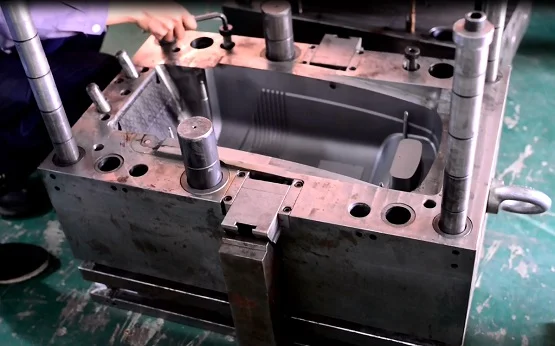

Low pressure molding keeps electronics safe. It protects them from dust, water, and damage. It makes parts strong and solid. They do not crack or break easily. It is also a cost-friendly way to seal delicate parts. To make the best-molded parts, you need to plan well. Think about materials and design. Also think about how strong you need the parts to be. Picking the Best Mold Machine A mold machine shapes and forms materials. Picking the right one is very important. It must fit the size, type, and pressure needed for the job. A good machine makes strong, smooth, and neat parts. A lousy machine can cause weak, rough, or broken pieces. The machine should be easy to use. If it is too hard to control, mistakes can happen. A simple machine saves time and effort. A good machine also uses less energy. This helps save money and makes better parts. A strong and well-built machine lasts longer and needs fewer repairs. Choosing the Right Material The material used in molding is vital. Some are soft, some are hard. Low pressure molding often uses plastics that melt and flow easily. The right material makes parts strong and long-lasting. The wrong one might break or not stick well. Some materials bend easily. Others are stiff and strong. If a part must handle heat, it needs heat-resistant material. Some materials last longer than others. Picking the best material helps make better products that last. Making a Better Mold System A mold system shapes parts. A well-made system fills up smoothly. It cools evenly. It does not waste material. It does not trap air. Air bubbles can make parts weak. A sound mold system makes perfect parts every time. The mold should also be easy to clean and fix....

Read More »Select the Best Custom Plastic Injection Molded Connector

A suitable injection molded connector keeps things working smoothly. A bad one can cause big problems. It can make parts lose, break connections, or stop things from working. Choosing the right one helps devices last longer. It makes them work better, too. This guide will help you. You will learn what to look for. You will see which materials are best. You will know how to make a wise choice. Injection Molding for a Molded Connector Injection molding is the best way to make custom plastic injection molded connectors. First, plastic is heated until it melts into a liquid. Then, this melted plastic is pushed into a mold. The mold shapes it into the proper form. After that, the plastic cools down and hardens. Once it is solid, the connector is ready to use. This method is used to make strong and exact connectors. Many industries use injection molding. Car companies use it for connectors inside cars. Electronics companies use it for connectors. Medical companies use it for special connectors. Why Use Plastic Injection Molding in Connectors Plastic injection molding is very popular. It is fast and affordable. It makes many high-quality connectors at once. After a mold is made, it can produce thousands of identical connectors quickly. Since machines do most of the work, there are fewer mistakes. This means less wasted plastic, which saves money. Another reason people use it is because it allows for very detailed designs. This is helpful when making small or complex connectors. The process is also very reliable. The connectors come out the same each time, so they fit well and last long. Pick the Right Plastic Mold for Connectors A plastic mold gives the plastic its shape. Choosing the right mold is very important for a connector. A mold should be strong...

Read More »Common Applications of a Custom Wire Harness

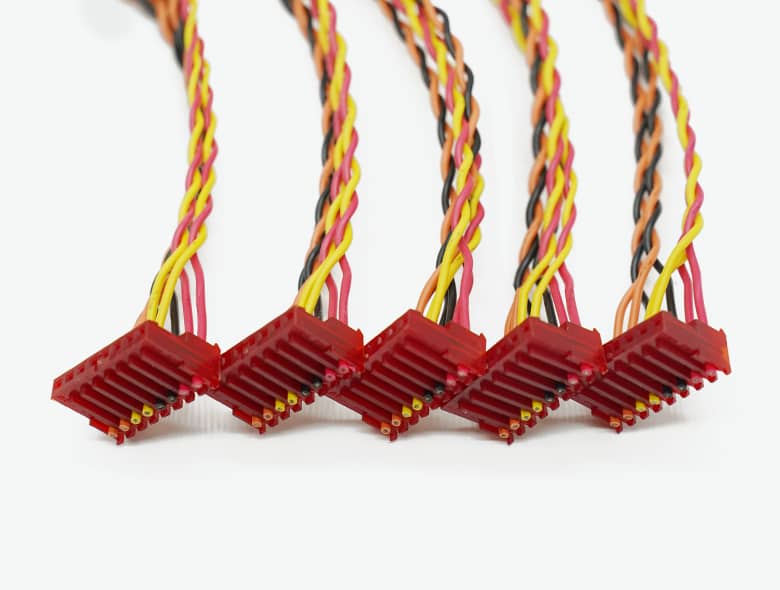

Wires can be messy. They can tangle. They can break. A Custom Wire Harness keeps them safe. It holds them together. It stops the damage. It helps in many places. Cars use them. Planes use them. Factories use them. Even hospitals use them. They make things work better. In this guide, we will learn where they are used. We will see why they help so much. What is a Custom Wire Harness, is it Vital? These wires carry power. They are tied together to stay neat. This keeps things safe. It helps machines work well. It makes machines last longer. Without wire harnesses, wires would be messy. They could break. This would cause big problems. Machines would stop working. Fixing them would be hard. Many industries use wire harnesses to prevent these issues. They help machines run better. They make things safer. A wire harness is like a body's nerves. It moves power to where it is needed. It keeps things running right. It protects wires. It helps machines last long. Without it, machines would break often. Fixing them would be hard. That is why wire harnesses are essential. Wire Harnesses are Best for Vehicles An engine harness helps the engine start and run. Without engine wire harnesses, wires could tangle. This could be unsafe. Wire harnesses help with safety, too. They connect airbags, GPS, and backup cameras. Electric cars need them to link the battery to the motor. This lets the car run well. Without them, electric vehicles would not work. Cars need many wires. These wires power lights, windows, and locks. They help with speed and brakes. They also show essential info on the dashboard. A wire harness keeps everything working. It stops wires from coming loose. It keeps cars safe. Without it, cars would...

Read More »Are Custom OBD Connectors Better Than Standard OBD Ports

Cars have OBD ports. These ports help check for problems. Standard ports do not always fit well. A loose fit can cause issues. It can make the connection weak. It can make car checks harder. Custom OBD connectors fix this problem. They grip tighter. They connect faster. They last longer. They help with easy car checks. In this guide, we will see how they work. We will learn why they might be better for you. What Is an OBD Connector? An OBD connector is a small plug in a car. It connects to a tool called a scanner. This scanner checks if the vehicle has a problem. If there is a problem, the scanner shows a code. This code helps a mechanic or car owner know what is wrong. Every car has an OBD port. Without it, finding car problems would be complex. It would take more time and effort to fix issues. The OBD system controls the car's engine, fuel, and other parts. If something goes wrong, the OBD connector helps find it fast. Car owners and mechanics use OBD scanners to read the codes. This makes fixing cars easier. Without an OBD port, people would have to check each part by hand. That would take more time and cost more money. Standard vs. Custom OBD Connectors Most cars have a standard OBDII port. This port is the same in all vehicles. A simple scanner can check for problems. A custom one is different. It is made for special needs. It may fit better, work faster, or have extra features. Some cars need a custom OBD-connector to work well, but most do not. If a vehicle has unique tuning or additional systems, a custom connector may help. A standard OBD port checks common problems, like engine trouble. It...

Read More »Properly Install a New Automotive Wire Harness

A vehicle needs a good Automotive Wire Harness. It connects essential parts. It makes sure power flows correctly. If wires are not in place, the vehicle may not start. Lights may not work. It could even be unsafe. Every wire has a job. It must be connected. A good harness prevents problems. It stops short circuits. It makes sure all parts get power. It also makes repairs easier. Installing it the right way is essential. It helps prevent accidents and keeps the car running well. Gather Every Tool and Automotive Wire Kit You Will Need Gather everythings you need for this. You must also check that your automotive wire kit has all the correct parts. Make a list of everything so you do not forget anything. The job will be much easier and faster if you have all your tools and parts ready. A well-organized workspace will also help you. It will help you keep all in order. It also helps to avoid any confusion during installation. Always Disconnect the Car Battery First So You Stay Safe Safety is the most essential part of working with car wires. If the wires are not disconnected then it could harm you and your wires harness. It might damage the wires or even your entire car. Taking out the battery ensures no power runs through the wires while you work. Start by removing the negative terminal first, then the positive one. This will help stop any electrical problems. Ensure the battery is placed somewhere safe where it won't cause any danger while you work. Remove the Old Automotive Wire Harness Gently Carefully take out the old automotive wiring harness. Do not pull too hard because this could damage other parts of your car. Go slow and be patient. Label every wire as you...

Read More »Is Low Pressure Molding Better for Sensitive Electronics

Low pressure molding covers delicate electronics like a soft shield. It keeps them safe from heat, dust, and damage. Some methods are too rough and break parts. Others do not protect enough. This method is just right. A unique material melts and flows over parts smoothly. It does not press too hard. When it cools, it forms a strong shell. This stops water, dirt, and damage. Many industries use this method. It helps electronics last a long time. Let's see why it is the best choice. Low Pressure Molding Keeps Tiny Parts Safe Small electronics are very delicate. They can break so quickly if not handled carefully. Low-pressure molding gently covers these tiny parts. It does not press too hard. Other molding methods use strong force. That force can damage circuits. When circuits break, the device stops working. Low-pressure molding applies a soft, even layer. It keeps everything safe. This method protects delicate devices. It helps them last longer. It keeps circuits, sensors, and chips from getting damaged. It is the best way to keep small parts safe. Uses Special Protective Materials Low-pressure molding uses unique protective materials. These materials are strong. They shield electronics from heat, water, dust, and dirt. Heat can cause electronics to overheat. Water can cause rust and short circuits. Dust can clog small parts. Dirt can make things stop working. The protective materials stop all these problems. They keep fragile parts safe. Even though the cover is challenging, it is gentle. It does not press too hard on the device. That makes it perfect for delicate electronics. It is excellent for medical tools. It is terrific for car sensors. It is great for factory machines. It protects electronics from harmful conditions. Low Pressure Injection molding Works With Smart Mold Systems New mold systems make low-pressure...

Read More »What Sectors Use Custom Plastic Injection Molded Connectors

Some things need unique Plastic Injection Molded Connectors to stay together. These pieces are made very carefully to fit just right. They are super strong and last a long time. Many places need these pieces so machines, tools, and other things can work correctly. These unique pieces make sure things don’t break and stay in place. Let’s look at all the areas that need them! Vehicles Need Plastic Injection Molded Connectors to Work Cars, trucks, and buses have lots and lots of little parts inside them! molded connectors help these big machines run. They help lights turn on, doors lock, and radios play music. These small plastic parts are super special! They are light, so cars do not have to work too hard. They do not get rusty, even when it rains or snows. That means cars last a long, long time! If cars did not have molded connectors, they would break faster and cost more to fix. These little plastic parts help cars be strong and safe! Hospitals use Plastic Injection Molded Connectors Doctors and nurses use special machines to help sick people get better. Molded connectors are inside these machines to help them work! They are in heart monitors, X-ray machines, and even tiny hearing aids. These pieces must be super strong and very clean. If they were dirty or broken, the machines would not work right! That would be bad for sick people. molded connectors help doctors and nurses save lives every day! Molded Connectors are Also In smart Gadgets Phones, TVs, computers, and video games all need molded connectors to work! These small parts help buttons turn on, and screens light up. Without them, headphones would not play music, and smartwatches would not tell time. These plastic parts also stop things from getting too hot and...

Read More »Use Cable Assemblies in the best and simplest ways

Cable Assemblies help things work. But they need to be used correctly so they do not break. They will last longer and work better if you take care of them. There are simple steps to keep wires safe and strong. If cables are put in place correctly, they will not get damaged. Good wire care means things will work better for a long time. Pick the Very Best Cable Assemblies for What You Need Cables are like magic strings! They help things work! Some cables bring power, like the power that makes lights turn on, and computers work. Some cables move things, like pictures, sounds, and words! Every cable has an exceptional job! If you pick the wrong one, things will not work right. That is not fun at all! Picking the right one makes everything easy and happy! Look at how long the cable is! If the cable is too short, it will not reach where you need it! That is super frustrating! If the cable is too long, it can get all messy and tangled like a big spaghetti pile! You do not want to trip over messy wires! That is not safe! Pick strong Cable-Assemblies, too! Some Cable-Assemblies are robust and can fight heat, water, and bumps! That helps them last a long, long time! Check the ends of the cable! The wrong ends will not fit! That means you cannot plug them in! That is a big problem! Ensure the cable you pick has the proper ends so everything fits perfectly! A suitable cable makes everything easy, smooth, and happy! How to Keep Your Wires Neat and Nice Messy, tangled wires are not good at all! They twist and turn and get all jumbled up! That can make them break! And if they fail, nothing...

Read More »Is a Custom OBD connector a vital part for machines

Cars and machines need to know if something is wrong. But how can they tell? A special plug called a Custom OBD connector helps them talk! This plug tells people if a car or machine needs fixing. It makes sure everything runs smoothly and does not stop working. When cars and machines have problems, this plug helps fix them fast! Let's see why this little plug is a very, very big deal! What is a Custom OBD connector? An OBD plug is a super special spot on cars, trucks, and big machines! It is like a tiny helper that tells you when something is wrong. When a machine is feeling sick, the OBD plug sends a message, like a bit of alarm, saying, "Help! Fix me!" This is super good because it helps people know what is wrong before things get terrible. When a special OBD plug is used, it works even better. It makes sure that machines send the best and most precise messages. This means machines can stay happy and work really well for a long, long time! Why a Special Custom OBD Connector is Needed Not all machines are the same! A regular OBD plug is made for most cars, but other machines need something just right for them. A special OBD plug is made to fit perfectly. It makes sure everything connects right. It helps machines talk to tools in the best way, with no mistakes at all. This makes fixing problems super fast, super easy, and super good. Machines can keep working without stopping too much, and that is awesome! Why a Special OBD Plug is Super Helpful Finds Problems Fast: A special OBD plug helps find problems really, really fast! That means no long waiting. No guessing. No big worries. Fits Just Right: Special...

Read More »Sectors that Use Custom Low Pressure Molding

Some things need Low Pressure Moldings so they do not break or get hurt. These covers help things last a really, really long time! They keep things secure from bumps, water, and dirt. Big jobs like making cars, building big machines, and making tiny computer parts all use these. Without covers, things could break too fast! Let's learn more about who needs these covers and why they are so important! Low Pressure Molding Helps Phones & Computers Stay Strong Phones and computers have lots of tiny, tiny parts inside. These parts are super important because they make everything work. But these little parts can get hurt very easily. If water splashes on them, they can stop working. If dust gets inside, they can break. If they get bumped or dropped, they might stop working forever! That would be really, really bad! Low-pressure molding makes a super strong cover around these tiny parts. It wraps them up like a warm, safe blanket. It keeps them dry. It keeps them clean. It keeps them safe from bumps and drops. This helps phones and computers last a long, long time! That means people can watch their favorite videos, play fun games, and talk to their friends without any problems. Low Pressure Molding Helps Cars Keep Moving Cars have lots and lots of little wires and tiny parts inside. These parts help the car move, stop, and turn. They make sure the car's lights turn on. They make sure the engine works. But these little parts need to stay safe! If water gets in, they can stop working. If dirt gets inside, they can break. If something terrible happens to them, the car might stop moving! That would be super scary! It makes a strong, tough cover that keeps these little parts safe. It...

Read More »