What Testing Methods Ensure a Reliable Custom Wire Harness

By Tina / 2025年4月11日

A custom wire harness is a bundle of wires put together to connect different parts of a machine. It keeps wires neat and safe. Without a good quality wire harness machine could be damaged. Even worse, bad wiring can be dangerous for people using the machines. This is why testing is crucial.

Testing helps ensure that harnesses wire is strong and safe. It also ensures that the harness will last long and not fail when needed. A good wire harness keeps machines running smoothly and safely.

Our Promise at QL-Custom Technology Ltd.

At QL-Custom Technology Ltd., we focus on making the best wire harnesses. Every harness we make is tested carefully to ensure it is strong and works well. Quality comes first, and we do not take shortcuts.

We make sure every harness is built to handle harsh conditions. We aim to create harnesses that last a long time and help machines run without problems. Our wire harnesses are designed to work well in any situation. They work well on all small devices or big machines.

Why Testing Custom Wire Harness Matters

- Without testing there could be many kinds of issues. It is a vital part of making wire harnesses. An untested wire harness can cause many problems to the machine.

- It can find the damaged parts. It also ensures that the harness will last and not break suddenly.

- Another big reason for testing is safety. A wire harness must follow strict safety rules. A bad harness could lead to power failures, electric shocks, or fires. Testing helps prevent these Issues. Testing makes sure every wire is in the right place and working correctly.

- Testing also checks if the harness can handle different conditions. Machines are used in places that can be hot, cold, wet, or dry. A strong wire harness should work in all these conditions without breaking.

Different Kinds of Tests for Custom Wire Harness

Many tests are done to check if a Custom Wire Harness is good. Each test helps find different problems to ensure the harness is safe and strong.

Visual Inspection

The first test is a visual inspection. This means looking closely at the harness to find any problems. It helps to find out the major issues early. It also helps to save money on the productions.

Continuity Test

The next test is the continuity test. In this test the flow of the electricity is tested carefully.

It makes sure the harness is built correctly. If a wire is not connected correctly, it can stop a machine from working, so this test is crucial.

Hi-Pot Test

The Hi-Pot test checks if the harness can handle high voltage without failing. It finds insulation issues and ensures electricity does not leak where it shouldn’t.

This test helps prevent electric shocks and short circuits. It is vital for harnesses used in high-voltage machines or sensitive electronics.

Pull Test

A pull test checks if the wires inside the harness are firmly attached. It makes sure they do not come loose when pulled or moved.

This test also checks if the connectors stay in place. It ensures the harness can handle pressure and will not fail because of loose links.

Functional Test

A functional test checks if the harness works correctly in real-world situations.

It tests how the harness performs when under stress. It also checks if it will last a long time without breaking. This is the final test before the harness is sent to customers to ensure it is ready for use.

Environmental and Stress Test

Machines have to work in many different conditions. This is why environmental testing is done.

This test checks if the harness can handle extreme heat and cold. It also checks if it can survive in water or very humid conditions. It even tests if the harness can handle shaking and vibrations.

If a harness passes this test, it can work in harsh conditions without breaking.

Automated Testing

Automated testing is another essential step. Machines help test auto harnesses faster and more accurately than humans can.

These tests help find mistakes quickly. They speed up the testing process. They also ensure that every wire and harness is checked before being sent out.

Select QL-Custom Technology Ltd. for Custom Wire Harness

At QL-Custom Technology Ltd., we make high-quality custom wire harnesses. Here are some reasons why you should choose us over other companies.

Expert Team & Certifications

We have a team of experts who understand everything about wire harnesses. We follow strict rules to make sure every product meets high-quality standards.

Our company follows ISO9001:2015 standards, which means we are serious about quality. Our team has many years of experience and knows how to make the best wire harnesses for any industry. We have certificates like Company Registered, ISO, UL. We also have RoHS For Copper, RoHS For Plastic Resin that proves that we use the best materials. Reach 72-138-1, PPAP Document List, Water-proof IP67, Flame Test shows how we test our items.

Our Custom Wire Harnesses That Pass Every Test

QL-Custom Technology Ltd. makes the best custom wire harnesses. These harnesses pass all safety tests and never fail. They help machines run well and stop problems before they start. They work in all places and all types of weather. These are built strong and made to last a long time.

Molded In-Line Fuse Holder

A fuse holder keeps wires safe by stopping too much power from flowing. Too much power can break wires or even start fires. Wires that get too much power can burn, melt, or stop working. Our molded in-line fuse holder prevents this from happening. It keeps circuits safe and blocks fires. It stops power surges and prevents damage. It keeps machines running smoothly and safely. It works well in wet, hot, and cold places. It also works in areas that move a lot.

Omron Switch Cable Relief

Wires that bend too much can break, which can stop machines from working. Broken cables are bad because they cause power loss and machine failure. It can also make switches stop working. Our Omron switch cable relief prevents this from happening. It helps wires last longer by keeping them from bending too much. It makes switches work better and keeps wires from becoming loose. It keeps power flowing and machines working well.

M12 Connector

M12 connectors hold wires tight and stop them from coming loose. Loose cables are bad because they can cause power loss and weak signals. It can also break machines. M12 connectors stop these problems. It helps signals stay strong and keep power flowing without any issues. M12 are used in factories, robots, and cars. These connectors are waterproof and dustproof, making them very strong. They stop signal loss and help machines communicate with each other.

Custom Coiled Cable

Coiled cables can stretch and shrink, making them perfect for moving parts. They help keep wires neat and stop them from getting tangled. Tangled wires can break and stop working well. These cables prevent that problem. These are used in cars, phones, hospital machines, and many other places. These cables are strong and bendy, lasting a long time without breaking. They work well in both hot and cold spots.

Micro D-Sub Cable

Some machines need small but strong cables. Micro D-Sub cables fit in tight spaces while still being very powerful. It sends signals fast and keeps them clear. This one does not lose power or signal strength. These are used in planes, army tools, phone networks, and big machines. These cables are robust and last a long time. It helps machines work well and stop signal loss. They are easy to install and meet all safety rules.

Visit QL-Custom Technology Ltd. We make strong, safe, and long-lasting wires. These are the best at keeping machines running well. They make harness wiring easy and stop problems before they happen. These harnesses keep signals strong and power flowing without fail. They help machines work their best every day!

Industries We Serve with Custom Wire Harness

We work with many industries and make harnesses for different uses. Our wire harnesses are used in the following ways:

- Car wire harness and transportation

- Medical equipment and healthcare

- Robotics and automation

- Industrial machines and electronics

- Military and aerospace

- Clean energy solutions

No matter your industry, we can create the perfect wire harness for you.

Complete Service Manufacturing

We handle everything from designing the harness to delivering the final product. We create and test prototypes to make sure they work perfectly.

We also produce harnesses in large quantities while maintaining strict quality control. Every product is tested before shipping. We offer fast global shipping so you get your harnesses on time.

Our Commitment to Quality

We are fully committed to making the best quality harnesses. We use only the best materials. Our company ensures every harness is tested for safety, strength, and reliability.

We also make sure to deliver on time, every time, so you can count on us for your wire harness needs.

A good wire harness must undergo many tests before it is ready. Without proper testing, a wire harness could fail. And it could cause significant problems and expensive repairs.

At QL-Custom Technology Ltd., we take quality very seriously. Every wire and electrical harness we make is tested to ensure safety, strength, and reliability. If you need high-quality wire harnesses, contact us. We provide the best-tested wiring harness solutions for every industry!

People Also Ask

What is a Custom Wire Harness test?

A Custom Wire Harness test checks if all the wires work the right way. It makes sure they are safe and will not break. It helps find weak or broken wires before they cause problems. If a wire does not work, a machine might stop working. Testing helps find and fix problems early. Every wire must pass this test before it can be used.

Why is testing a wire harness important?

Testing stops wire failures before they happen. It keeps people and machines safe from harm. A bad wire can make power stop or even start a fire. This can be dangerous. Testing helps find these problems before they get worse. It saves money and prevents accidents. Good wires help machines work well and last longer.

How do you check wire strength?

Pull the wires hard to see if they stay in place. If a wire comes loose, it is weak and unsafe. A strong wire should not move or break. This test ensures that the wires will not fall apart when used. Strong cables are essential for safety and long-lasting machines.

Why test for shorts?

A short circuit happens when wires touch in the wrong way. This can make sparks, which can start fires. A test makes sure cables do not cause shorts. If wires are touching where they should not, they must be fixed. Safe cables do not create sparks.

How do you check for bad connections?

Wires must be tight where they connect. Loose spots can stop power from flowing the right way. Tools help find bad connections. A good wire must fit tightly to work well. Loose cables can prevent machines from working and cause problems.

What is a load test?

Wires carry power to different parts of a machine. This test checks if a wire can handle much power without breaking. If a wire gets too hot, it is too weak. A good wire must carry power safely. This helps machines work without problems.

How do you test for heat damage?

High heat can melt wires. A melted wire can cause a fire. This test puts wires in heat to see if they stay safe. Wires must handle heat without melting or breaking.

Why test different temperatures?

Wires work in both hot and cold places. This test checks if they work in all temperatures. Cold can make wires stiff. Heat can make them weak. Wires must work in all conditions without breaking.

What is a UV exposure test?

Sunlight can damage wires over time. This test checks if wires can handle strong sunlight. Wires used outside must pass this test to last a long time. If a wire cannot handle sunlight, it may crack or break.

How do you test wire coating?

The coating protects wires from damage. This test scratches and rubs the coating to see if it stays strong. A good wire has a coating that does not wear off too soon. A strong coating keeps wires safe for a long time.

FAQs

Why test wire harnesses?

Testing finds bad wires and loose parts. Fixing them keeps things safe.

What is a continuity test?

This test checks if power moves through the wire. If the power stops, the wire is broken. This test finds bad cables so they can be fixed.

What is a short circuit test?

This test finds wires that touch by mistake. Short circuits can cause sparks or fires. This test helps stop the danger.

What is a high-voltage test?

This test sends strong power through the wire. It checks if the Custom Wire Harness can handle it.

How often should wires be tested?

Wires should be tested often. Over time, they wear out. Testing finds problems early.

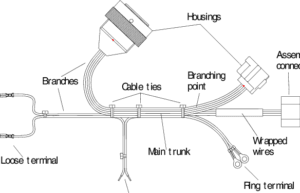

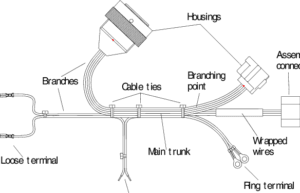

Designs of Custom Wire Harness