Select the Best Custom Plastic Injection Molded Connector

By Tina / 2025年3月16日

A suitable injection molded connector keeps things working smoothly. A bad one can cause big problems. It can make parts lose, break connections, or stop things from working. Choosing the right one helps devices last longer. It makes them work better, too. This guide will help you. You will learn what to look for. You will see which materials are best. You will know how to make a wise choice.

Injection Molding for a Molded Connector

Injection molding is the best way to make custom plastic injection molded connectors. First, plastic is heated until it melts into a liquid. Then, this melted plastic is pushed into a mold. The mold shapes it into the proper form. After that, the plastic cools down and hardens. Once it is solid, the connector is ready to use. This method is used to make strong and exact connectors. Many industries use injection molding. Car companies use it for connectors inside cars. Electronics companies use it for connectors. Medical companies use it for special connectors.

Why Use Plastic Injection Molding in Connectors

Plastic injection molding is very popular. It is fast and affordable. It makes many high-quality connectors at once. After a mold is made, it can produce thousands of identical connectors quickly. Since machines do most of the work, there are fewer mistakes. This means less wasted plastic, which saves money. Another reason people use it is because it allows for very detailed designs. This is helpful when making small or complex connectors. The process is also very reliable. The connectors come out the same each time, so they fit well and last long.

Pick the Right Plastic Mold for Connectors

A plastic mold gives the plastic its shape. Choosing the right mold is very important for a connector. A mold should be strong so it does not break. It should also be the right size and shape for your project. Some molds are made of metal, while others use rigid plastic. The best mold depends on how many connectors you need and how long you will use it. The mold can crack or wear out too fast if the mold is weak. A well-made mold will last a long time. It will help make strong, perfect connectors every time.

How to Find the Best Injection Molders

A good injection molder is a company that makes plastic connectors using molds. Finding the right company is essential. The best molders make high-quality connectors. They should have good reviews and experience making connectors. They should use strong materials and advanced machines. Some molders work with big connectors, while others make small, detailed connectors. A good molder will help you choose the best design and materials for your project. They will ensure your connectors are strong, durable, and made correctly.

Types of Injection Molds

Not all injection molds are the same. Some are simple, while others are complex. Simple molds make basic shapes for connectors. They cost less and are easier to make. Complex molds can create detailed or multi-connector designs. They take more time and money to make but allow for unique shapes and features. Some molds can make many connectors at once, which speeds up production. You will need a high-precision mold if your connector has tiny holes, thin lines, or moving pieces. Choosing the right mold helps make sure your connectors come out perfect every time.

Custom Plastic Injection Molds

Sometimes, a standard mold will not work for your project. In this case, a custom plastic injection mold is the best choice. A custom mold is designed for your exact needs. You can pick the size, shape, and material. Custom molds cost more at first. But they save money over time. They help reduce waste and make better-quality connectors. Many industries use custom molds. Car companies, medical companies, and electronics makers all use them. A custom mold helps create connectors that fit perfectly and work better than standard ones.

Why High-Quality Plastic Molding Matters

Good plastic molding makes strong and durable connectors. If the molding process is not done well, the plastic may break or not fit together. High-quality molding prevents these problems. It makes sure connectors last a long time. Choosing the best materials is essential. Working with an experienced molder helps, too. Firm, well-made connectors improve the performance of the products they are used in. Whenever they are used, strong connectors help everything work better and last longer.

Buy the Best Custom Plastic Injection Molded Connectors

Seeking strong and long-lasting connectors? You need parts that keep wires safe and working well. You need parts that do not break under pressure. You need parts that last a long time and can handle tough jobs. The best ones are at QL-Custom Technology Ltd.. Their connectors are made with care and built to last. They use the best materials. They make sure your electronics and machines work smoothly. These connectors keep your equipment running for years. No need to worry about weak parts breaking or replacing them often. Get the best ones and make your machines stronger and safer!

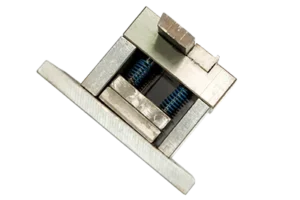

Durable Custom Plastic Injection Molded Connectors

Custom Overmolded plug

These plugs are strong and secure. They keep wires safe and in place. They stop loose connections that can cause problems. They protect wires from breaking, bending, or wearing out. They are made to last a long time, even in harsh conditions. These are perfect for cars, electronics, and machines. No need to worry about broken plugs or replacing them often. These plugs are built to last, providing strong, steady connections every time!

Custom ABS PC plastics

These are made from ABS and PC plastics. That means they are tough, heat-resistant, and do not break easily. They can handle heat, pressure, and rough conditions without melting or cracking. They are often used in factories, gadgets, and high-heat places. If you need strong and safe parts, these are a great choice. They handle tough jobs and keep your machines running. And these last a long time without damage.

Custom Rubber seal molding

These parts are waterproof and weatherproof. They keep out rain, dust, and dirt to protect your machines. They do not wear out fast, even in bad weather or extreme conditions. They are perfect for outdoor equipment, boats, and cars. They stop leaks and keep your machines safe from water damage. They are flexible, durable, and made to last for years.

Choosing the best plastic injection molded connector is simple. Use a strong mold. Work with experienced molders. Choose the best materials. Taking the time to make the right choices will save money. It will also lead to better products. Making connectors with high-quality plastic injection molding ensures reliability and durability. With the proper mold and the right process, you will always get strong, high-quality connectors.

The correct connector stays strong. It works well for a long time. Choosing wisely saves time, money, and stress. Follow these easy tips. Get the best one. Avoid future problems!