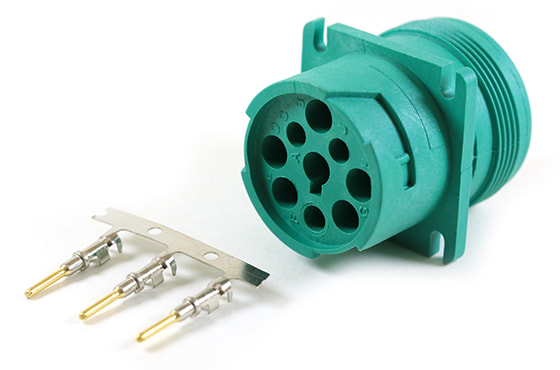

If a wire harness factory has control over the supply capacity of plastic molding materials, or has the ability to custom design and produce materials such as connectors, it will be of great help to the customer's required delivery time. Fortunately, we have the ability to customize molded connectors for customers, and we can effectively control this overall procedure. We not only have enough designers, but also several mold making workers, which is very effective for your molding projects. If you want to customize various types of plastic products to match your project, we have the ability to help you solve it.

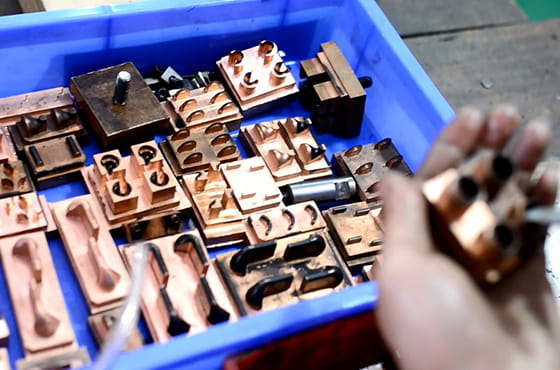

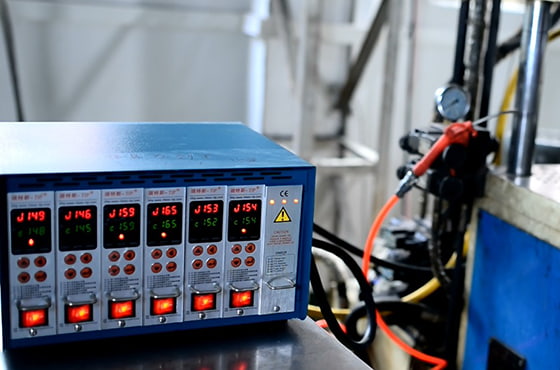

Molding works are divided into many types. From the material selection, what plastic needs to be molded already determines how the mold should be designed, what material the mold steel should be made of, and what standards the heat treatment of the mold should meet. And whether to use a vertical injection molding machine or a horizontal injection molding machine. So, first determine what plastic you need to use for molding

Get a Quick Quote

Mold Molding consists of discrete molding and horizontal molding. Vertical molding is often used for injection molding of wire plugs, connector rubber coatings, and small connector rubber cores. The horizontal forming machine is mostly used for waterproof boxes, lids, shells and covers of furniture and home appliances, etc.

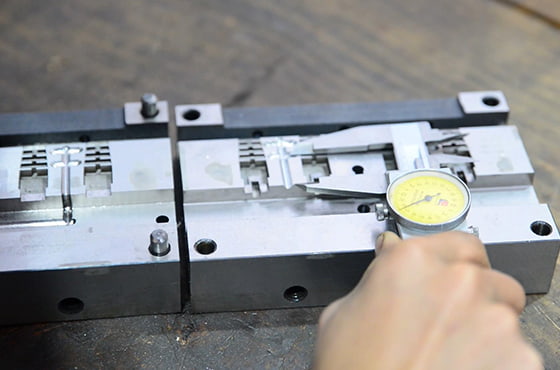

Get a Quick QuoteThe most common problem in injection molding is flashes. There is no other way to solve this problem. One is the precision of the mold, and the other is the mold closing line of the two halves of the mold. The more precise the mold is, the less likely this problem will occur. The other problem is shrinkage and marks, which are mainly determined by the drying time of the plastic material and the temperature and pressure adjustment of the molding machine. However, some rubber materials are very soft and have strong fluidity after melting in the molding machine, which may cause serious flash.

Get a Quick Quote

QL-Custom was originally purchased from a friend's company, but considering the quality requirements and meeting the different injection molding needs of various customers, we finally adopted a partnership approach to control the mold manufacturing workshop. This not only reduces costs for customers, but also saves the delivery time of mold builds. In addition, we are about to incorporate our partners’ workshops into the ISO quality management system, which will better standardize the quality of mold output.

The maximum molding size of QL-Custom is 1.2 meters long and 0.45 meters wide. There are essential differences between traditional plastic injection molding and blow molding. Blow molding can be used to make plastic chairs and automobile faceplates. If such products are also injection molded, the mold volume will be too large and the injection molding efficiency will be greatly reduced. The handling efficiency will also be unimaginable. Even if pulleys are used to push and pull, it will be difficult to quickly produce finished products.

We mentioned earlier that QL-Custom is already a partner in injection molding. We can evaluate the steel, processing, and design costs ourselves, so the quotation you get from our company must be at an advantageous price to help you get the project. Another, a 3D pre-printed product will be made if the solution not confirmed before mass production.

Since our mold manufacturing workshop has been established for a long time, we have accumulated a large number of cases, and we have learned many solutions to realize designs for customers. So no matter how complex your product is, QL-Custom has the ability to solve your mold manufacturing and injection molding solutions.

Generally speaking, the mold manufacturing cycle for injection molds is longer (up to 60 days), while the manufacturing cycle for plug molds is shorter (7-21 days). We can speed up the process according to your needs. That's why we must take control of the shop floor. Because of mold manufacturing, the stability of injection molded products does affect the customer's product delivery time.

We are alway here to help your wire harness business

Get a Quick QuoteIn order to make our customers trust us more, we will continue to update our frequently asked questions and knowledge, so that customers can learn more from our blog. And customers together progress, get a win-win situation.

Read MoreQL-Custom Technology Limited is an ISO9001:2015 professional company that specializes in Custom made Over molding cable assembly and wire harness. If you are looking for the best partner in plastic molding, low pressure molding (PCB over molding) and wiring, then you have finally come to the right place where you will be served by a highly experienced and competent team – leaders in the industry. We manufacture high quality parts that are used in a wide rang...

Read More