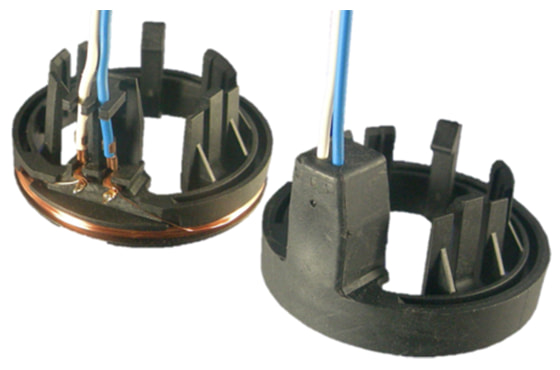

Low pressure injection molding is a very easy to useLow injection pressure injects packaging material into the mold cavitues, a packaging engineer with rapid curing molding Law. To achieve insulation, temperature resistance and impact resistance, shock-absorbing, moisture-proof, waterproof, dust-proof, resistantChemical exposure. Application: circuit boards, electronic plug-ins Type, wiring harness, battery, switch, LED light, Comprehensive volume, etc.

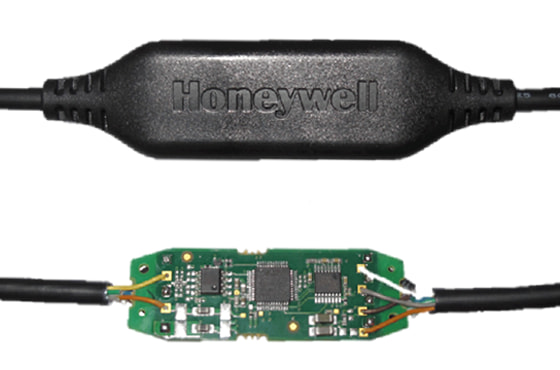

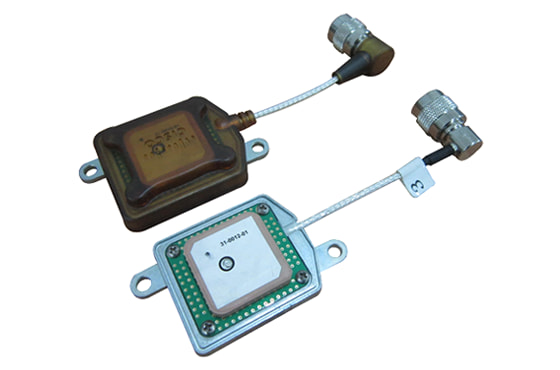

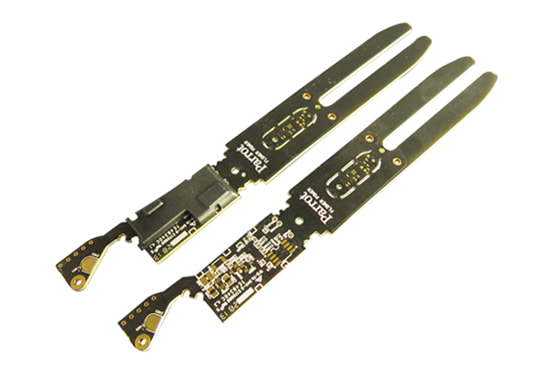

Low-pressure injection molding is very friendly to ICs, PCB circuit components, magnetic rings, and LEDs. These components often lose their original functions under high pressure when using ordinary injection molding. The molding under very low pressure effectively protects the normal function of the components. Especially when amber translucent PA rubber is used for molding, the original body can still be seen. Especially in components with LED light, the light can be seen more clearly during product operation. However, compared with TPE TPU PVC, this material is not resistant to alcohol or acid and alkali corrosion.

Get a Quick QuoteMost of the molding is high-pressure injection molding. These moldings are our common vertical injection molding machines. Low-pressure injection molding effectively broadens the business scope. In our previous molding experiments, high-pressure (common injection molding machine) injection molding After being molded onto a sensitive component, the function of the component will lose data. However, in low-pressure molding, when the melted rubber is injected into the mold cavity, the pressure is uniform, and the mold cavity is not filled under instantaneous high pressure, thus effectively protecting the function of the component. Integrity.

Get a Quick Quote

The biggest feature of low-pressure injection molds is that plastic is fed from the side. This is different from the way many vertical molding machines feed plastic. Ordinary molds sprue on the upper half of the mold, while low-pressure injection molds inject from the side. In addition, The molding machine has a great feature. The plastic melting container and the injection molding machine are separate. This is to better control the temperature of the plastic after it is liquefied.

Regarding low-pressure molding rubber, the most original brand of rubber is Technomelt. Currently, there are many brands produced in China. These are generally reliable. After all, the cost of using all Technomelt brands is too high and cannot be used to protect components. Instead of damaging it, higher-end materials are used which increases the cost.

If you need to customize a similar one, you can contact us. We will wholeheartedly customize a USB converter for you and use low-pressure injection molding technology to make it more beautiful.

There are not many low-pressure molding cases for LEDs, but some extremely high-end products may use sensitive ICs in order to design more perfect products and better control the lighting effects. At this time, our low-pressure injection molding process is needed.

Low-pressure injection molding is indeed rarely used in various industries, but it is necessary to prepare for this process. For example, automotive products rarely use low-pressure injection molding, but components are often needed to be added to modified products, and our process can just meet the needs of customers.

We are alway here to help your wire harness business

Get a Quick QuoteIn order to make our customers trust us more, we will continue to update our frequently asked questions and knowledge, so that customers can learn more from our blog. And customers together progress, get a win-win situation.

Read MoreQL-Custom Technology Limited is an ISO9001:2015 professional company that specializes in Custom made Over molding cable assembly and wire harness. If you are looking for the best partner in plastic molding, low pressure molding (PCB over molding) and wiring, then you have finally come to the right place where you will be served by a highly experienced and competent team – leaders in the industry. We manufacture high quality parts that are used in a wide rang...

Read More