Custom Cable Labels and Wire Markers, Harness Tags

Custom cable labels, also known as wire markers or harness tags, are used to identify and organize wires and cables. These labels display words, numbers, or barcodes, allowing workers to distinguish one wire from another. When wires are clearly labeled, it is easier to identify and resolve problems, as well as perform repairs. Labels also help keep people safe by lowering the chance of wiring mistakes. You can see labeled wires in data centers, factories, cars, and many other places. Good labeling saves time and helps work move faster. Types of Custom Cable Hire Harness Labels: Categories There are many kinds of cable and harness labels. The main types are thermal transfer labels, laser printing labels, inkjet printing labels, embossed labels, and handwritten labels. Thermal Transfer Label Thermal transfer labels are printed using a special printer and an ink ribbon. Heat from the printer causes the ink from the ribbon to move onto the label. These labels are typically made from durable materials such as polyester or vinyl. The text and barcodes come out very clear and sharp. These labels are resistant to fading and can withstand heat, oil, and rubbing. Laser Printing Label Laser printing labels is made using a standard office laser printer. The labels come on sheets and are made for laser heat. These labels provide clean and sharp text without the need for wet ink. Many laser labels come with a transparent top layer that protects the print. They are suitable for small and medium projects because they can be easily created at the office. Inkjet Printing Labels Inkjet labels are printed using inkjet printers. These printers use liquid ink, so the label paper must be special to hold the ink. One significant advantage of inkjet labels is that they can be printed in color....

Read More »High-Flex Custom Wire Harness for Moving Equipment

A high-flex custom wire harness has strong wires that can be bent, twisted, and moved around many times without breaking. These harnesses are made to protect users at all times when there are moving parts. The makers of the harness use soft but strong wire, colorful wraps, and well-organized designs to keep it from breaking. Many groups choose these systems because it's important to protect data, communications, and power in equipment that is always running. Use a high-flex harness to work steadily for a long time, with only a few breaks. Moving Tools Need High-Flex Harness Parts Tools that move around a lot need wires that can bend all the time. A frayed wire could break and quickly cut the line, which would hurt the machine. A good harness makes everything work well. This helps motors, arms, belts, and joints get the right data or power flow. Less heat, tension, and pulling forces are other benefits. A lot of brands use custom wire harnesses, custom cable and wire harnesses, and full custom wire harness assembly solutions for this reason. When properly planned, each harness lasts longer and is safer to use. Built by Trusted Experts You want a skilled team that knows how to plan and build a strong, flexible harness. Knowing the product's anticipated bend force, motion patterns, stable use, and daily stress is crucial for a custom wire harness manufacturer. They use clean methods and strict testing on every part. A lot of groups work with a Chinese custom wire harness supplier because they do good work, get things done quickly, and charge fair prices. Brands are also looking for teams that can help with custom wire harness manufacturing, custom wire harness assembly, and careful custom wire harness planning. Uses in Many Moving Systems These high-flex sets can...

Read More »Modular Custom Wire Harness for Fast Integration

Teams are able to focus on what really matters thanks to a custom wire harness assembly that ensures all machines link fast, work steadily, and remain secure. There will be no dangling cables, tangled mess, or time-consuming inspections thanks to this construction style, which maintains all wires gathered in one tidy, solid channel. The setup process is simplified and teams save time by not having to guess which line goes where because the wires stay in one distinct path. Because they can see each line clearly and make adjustments fast when necessary, this makes every shift go more smoothly. Because it provides a clean, stable, and long-lasting link, this sort of arrangement is trusted in many sectors, including car repair, shop equipment, and production lines. Custom Wire Harness: Easy Fit in Any System Both big and small machines can benefit from bespoke Custom wire harnesses and cable assemblies because of the versatility they offer in terms of form, bend radius, tool size, and odd route accommodation. You have complete control over the build's placement within your system by selecting the wire type, length, cut, and shape. With the cables neatly organized in predetermined pathways, teams can fix components fast since they can see and reach every cord. Because workers aren't left to guess where each line goes and cables never intersect in odd routes, this well-organized arrangement helps cut down on mistakes. It is also useful in situations where tools need to be swapped out regularly or when new devices need to be connected quickly. With this style, work flows easily with little interruptions. Extra Advantages of Modular Harness Quick Change: Changing out individual components of a modular harness is a breeze and won't ruin your setup every time. As a result, teams are able to do jobs more quickly....

Read More »Vehicle Signal Automotive Wire Harnesses for Data Networks

Automotive wire harnesses make it easy and safe for big vehicles like cars, trucks, and construction equipment to send and receive accurate data. Each harness puts a bunch of small wires into one smooth, straight path, which makes it easy to follow each connection. This tight construction keeps the wires away from dirt and dust, even when it's wet or muddy. The harness's strong wrap and solid parts will keep the cables from shaking. They also make sure that the machine's moving parts stay safe. Your tools can work safely, reliably, and for a long time because of this setup. Vital Uses of Automotive Wire Harnesses These automotive wire harnesses keep the data clean and steady, so each part of the machine can connect quickly and without any problems. The strong wrap will help keep the wires safe from heat, friction, and sharp bends. If the wires are safe, the whole system can handle regular maintenance for a long time. The strong seals on both ends of the wires keep dirt and water out, so they won't wear out quickly. It helps save time and money on repairs. A clean link and safe path will make your system work better. Built for J1939 Use Automobile wiring harnesses are made to easily and beautifully support the J1939 data format. They use the right connector type, shield, and cable size to make sure that data flows smoothly. Because of this, the data transfer between the engine, brakes, sensors, and other parts of the vehicle happens more quickly. When the connection is clean, the machine doesn't break down as often and doesn't wear out as quickly. This helps make the trip safe and comfortable. With the right plugs and setup, you can still get good data even on rough job sites. Easy Fit...

Read More »High Grade Automotive Wire Harnesses for Car Lighting

On a daily basis, high-quality vehicle lighting can't do its job without stable and secure Automotive Wire Harnesses. The lights need to be turned on quickly. Their light must not fade. In low light or inclement weather, they must not let you down. Having a reliable automotive wire harness in place makes sure that power moves freely from one component to another. Very carefully, it connects control units, sensors, lights, and switches. J1708 OEM cables offer a higher level of assurance in the clean flow of data and fast signal speed in vehicles of all sizes, from compact automobiles to large trucks. Lights may be turned on instantly with the aid of these cords. They also assist lights maintain their brightness for extended periods of time. Road safety for both drivers and riders is greatly enhanced by this. Car Lighting Needs High Grade Automotive Wire Harnesses Every time you start your car, make sure the lights are on. On dark roads, there is no way to turn back. No matter the weather, they keep on working. Lighting could be affected by a frayed cable. Moreover, it has the capability to turn off light bulbs simultaneously. A high-quality Automotive Wire Harnesses keeps the power supply robust and smooth by using the best wire for automobile harness duties. It defends against engine heat. The winter air is less likely to chill you when you wear it. Additionally, it is resistant to shaking caused by lengthy truck routes and harsh roads. It is easy to maneuver and remains steadfast on its course. As a result, light lines are suitable for regular usage in any road condition. High Grade Automotive Wire Harnesses Products Designed specifically for truck lighting, these reliable cable types guarantee smooth data transfer and can endure the harsh conditions of heavy...

Read More »Custom Wire Harnesses for Industrial Manufacturing Projects

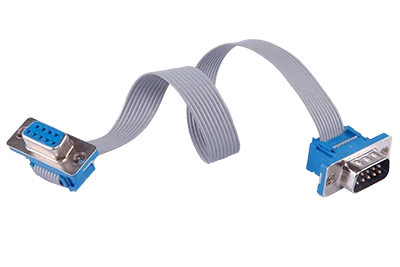

Custom wire harnesses are essential for the efficient operation of machines of all sizes in busy environments. These harnesses keep wires safe, stable, and away from heat, dust, sharp edges, and rough parts. They do this by bundling several stray wires into one clean thread. When the cables are neatly stored, the whole area becomes quieter, less cluttered, and safer for everyone who works there. These harnesses help keep things tidy and let teams move around more easily. These harnesses fit so well that it's usually easy to put them on, even in wide open spaces. Many teams use custom wire harnesses when daily strength and readiness are very important. The Vital Uses of Custom Wire Harnesses A good Custom Wire Harnesses keeps all the wires in one place so they don't slide, twist, or scrape against each other. This makes the work line safer, lowers the risk of accidents, and stops tools from breaking down when you least expect it. When the cables are neatly organized, the machine runs more smoothly and doesn't stop as often. With custom wire harness assembly services, you build the set with your own tools, making sure that every wire, wrap, plug, tube, and clip fits your project perfectly. This way, the wires will last longer and be better protected, even after long shifts. Many teams trust custom wire harness manufacturers because they make high-quality products that last a long time and have a lot of thought put into their designs. Workers can do more in less time, with less stress on their tools, and with less effort overall when they use custom harnesses. For big businesses, it's also important that they help teams stay in line with strict safety rules. Flat Ribbon Cable: Soft Shape for Tight Spots Flat ribbon cable is easy...

Read More »Custom Wire Harness for Complex Electrical Circuit Projects

Almost every tool, car, machine, and appliance needs its own wire harness. They make sure that power is safely transferred. A strong wire harness keeps a project with many parts organized and easy to understand. This makes the system safer and easier to fix. Many groups look for companies that make custom wire harnesses so they can get harnesses made to their exact needs. When done well, specialized work makes even the hardest jobs easier. Importance of Smart Harness Plans A well-designed harness can make a system last longer. When the wires are organized and the right kinds of wires are used, there are fewer problems. Also, repairs go faster because each wire is easy to find. A lot of builders choose custom wire harness assembly because it gives them wire sets that are clean, strong, and made just for their project. When you work with a qualified custom wire harness maker, you get parts that have been tested, are reliable, and are built to last through daily use. Careful preparation protects wires from vibration, dust, and damage in addition to lowering temperatures. Key Uses in Many Fields Custom wire harnesses are everywhere in modern life. You can find them in cars, home appliances, lights, machines, and even tiny gadgets. A harness is a helpful way to keep wires safe and organized. They not only lower the temperature of the system, but they also make it last longer. A lot of teams use custom wire harness design services to make harnesses that work in tight spaces or can hold special equipment. With a custom design, teams can get more done in less time because every wire is carefully labeled and placed. Suggested Cables for Complex Jobs Custom XLR Cable A custom-made XLR cable will let you send audio without any...

Read More »Flexible and High-Temp Automotive Wire Harnesses Solutions

Modern cars are equipped with advanced technology. There are safety systems, screens, sensors, and many small computers. All of these need power and clear data signals. If the Automotive Wire Harnesses is weak or poorly organized, these systems can fail at the most critical time. Clean, safe wiring is not just a minor detail; it's a crucial aspect of electrical safety. It is one of the most essential components of the entire vehicle. A good automotive wire harness design works like a map for all the wires in the car. It shows where each wire goes and how it is held in place. The harness keeps wires away from sharp metal, hot parts, and moving parts. It protects them from dust, dirt, and constant bumps from the road. When the harness is planned well, the car is easier to fix, test, and upgrade. A technician can follow the harness and quickly find the right line. Advantages of Flexible and High-Temp Harnesses Built for Heat and Tight Spaces The inside of a car is a harsh place for wires. Many cables pass close to the engine, which can get very hot. Others run near exhaust parts or sharp brackets. Some must bend around tight corners inside the dash or under the floor. A high-voltage automotive wire harness can face even more heat and stress than normal cables. That is why these automotive wire harnesses need jackets and materials that can handle high temperatures without cracking or melting. A strong harness for OBD and GPS work should: Bend safely in tiny spaces without damage Stand up to engine heat, dust, and mud for years Resist oil, fuel, water, and other common fluids Keep signal loss low so OBD and GPS data stay clear When the automotive wire harness manufacturing process is...

Read More »Heavy-Duty Automotive Wire Harnesses for OEM Precision

Automotive wire harnesses that are strong are necessary for cars to work well every day. These wire sets will stay strong no matter how hot or shaky the car gets. Every set has strong housings and safe parts that protect the wires from dust, water, and heat, among other things. These parts hold a lot of links in place, which keeps the work going smoothly. These strong setups make things last longer and give a wide range of vehicles reliable power paths. Many auto shops like these sets because they are fast and last a long time. You can use them with both old and new cars. Also, they make it easier for technicians to quickly test and fix lines. Essentiality of Heavy-Duty Automotive Wire Harnesses By buying high-quality wire sets, you can keep all the moving parts of your car talking to each other. These parts all work together to move energy and information around the car. A neat and safe wiring setup makes it less likely that someone will get hurt by wires sticking out, and it also makes the car safer. A lot of companies try to make sets that don't shrink in hot weather and stay tight no matter how fast or slow the car is going. These sets can help you connect plugs like OBD and DB. Techs can also quickly find problems with good setups. If you do this, the car will last longer and need fewer repairs. Automotive wire Harnesses Fit for Many Car Jobs These Automotive Wire Harnesses sets can be used for many things by cars, trucks, and work vans. They carry a lot of little lines in a neat way. This keeps the inside of the car from getting messy and saves space. The tech has access to tools for...

Read More »Secure Automotive Wire Harnesses for Vibration-Heavy Zones

Every day, cars travel long distances, over rough ground, and around sharp turns. These areas shake a lot. This shaking could break the wires if they aren't made well. That's why it's so important to have good parts for your car's wiring harness. They hold the wires in place. They stop the cuts, pulls, and heat damage. Cars with high-quality automotive wire harnesses run well, safely, and reliably for a long time. A lot of companies that make wire harnesses for cars now work hard to make sure that their products stay stable even when they are in places where there is a lot of shaking. These companies use high-quality, tried-and-true parts and creative designs to protect the cables even when the car body shakes a lot. Working Process: in Hard‑Shake Spaces Shaking can break automotive wire harnesses that aren't strong. The vehicle harness wire, on the other hand, is safe and secure if it is well-made. The engine compartment, gearbox and undercarriage are all places where the car shakes a lot. The wires need to be held tightly and wrapped gently. A well-designed wire harness keeps wires from touching, twisting, or breaking, which keeps the vehicle's electrical system safe. High-quality automobile wire harness suppliers use coverings that are soft but strong, fasteners that are safe, and pathways for all of the wires that are well-protected. This makes things last longer, easier to work with, and fewer mistakes. Technical teams may also use it to check or fix cables more quickly. Useful Sections of Automotive Wire Harnesses Different parts of a car move in different ways. These areas get hard shakes every day. Best used with high-quality wire harness tools for: areas of the engine that get hot and areas of the battery that drain quickly. Mobile or swivelling...

Read More »