Custom Wire and Cable

End-to-End OEM/ODM Solutions: Your Design, Our Expertise, Zero Compromise

Get a Quick Quote

Our recommendation of

custom wire and cable materials

Different materials are used in different scenarios. We will make

professional recommendations based on customer needs. QL-Custom has

a professional team. We will accurately recommend customized wire

and cable materials based on your needs to ensure scientific

material selection, excellent performance, and meet project-specific

requirements.

- Conductor Materials

- Insulation Materials

- Sheath Materials

- Shielding material

- Filling material

Copper

High conductivity (58-60 MS/m), low resistance, minimal transmission loss; excellent ductility allowing drawing into ultra-fine wires (e.g., 0.05mm diameter); poor oxidation resistance requiring tin/silver plating for protection.

Silver-plated copper

Conductivity approaching pure silver, low high-frequency loss; heat-resistant but prone to oxidation blackening.

Nickel-plated copper

Hard wear-resistant coating, acid/alkali corrosion resistance, strong thermal stability.

Tin-plated copper

Tin coating enhances oxidation resistance, corrosion/sulfurization resistance, stable soldering with low cost.

Thermocouple Conductors

Paired dissimilar metals (e.g., NiCr/NiAl) generate stable thermoelectric potential, extreme temperature endurance.

PVC

Features: Low cost, excellent flame retardancy (oxygen index ≥28%). Low temperature tolerance (-15°C–70°C), prone to softening at high temperatures.

XLPE

Rated temperature increased to 90°C after cross-linking (short-circuit tolerance up to 250°C). High dielectric strength (>20 kV/mm), resistant to environmental stress cracking.

Rubber (e.g., EPDM, Silicone Rubber)

EPDM: Excellent ozone/weather resistance (-50°C–150°C).

Silicone rubber: High-temperature resistance (-60°C–200°C), superior flexibility.

Silicone rubber: High-temperature resistance (-60°C–200°C), superior flexibility.

Fluoropolymers (PTFE, FEP, PFA)

PTFE: Temperature resistance (-200°C–260°C), low friction coefficient, difficult processing.

FEP: Melt-processable, strong chemical corrosion resistance.

PFA: Heat resistance (260°C), corrosion resistance, low friction, superior insulation.

FEP: Melt-processable, strong chemical corrosion resistance.

PFA: Heat resistance (260°C), corrosion resistance, low friction, superior insulation.

Kapton

Extreme temperature tolerance (-269°C to +400°C); High strength; Electrical insulation; Corrosion resistance.

Fiber glass

High strength-to-weight ratio; Heat resistance (-50°C to 500°C); Corrosion resistance; Electrical insulation.

PVC

Wear-resistant, flame-retardant, adjustable softness with plasticizers. Brittle at low temperatures (requires cold-resistant plasticizers).

PUR

High wear resistance (10× higher than PVC), oil-resistant, hydrolysis-resistant, low-temperature tolerance (-40°C), suitable for dynamic bending.

LSZH

Low smoke emission and non-toxic combustion, IEC 60754-1/2 compliant. Lower mechanical strength, requires flame retardants additives (e.g., aluminum hydroxide).

Cross-linked PVC

High-temperature resistance (125°C); Creep resistance; Chemical corrosion resistance.

TPE

Combines rubber-like elasticity with plastic moldability; Low-temperature resistance (-60°C); Wear-resistant; Halogen-free and eco-friendly.

Mica FG Cable

Ultra-high temperature resistance (450°C+); Fireproof; Superior insulation; High mechanical strength.

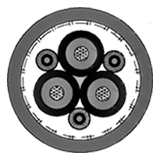

Copper Braided Shielding:

Coverage ≥85%, high-frequency shielding effectiveness >60dB (e.g., CAT6A cables).

Aluminum Foil Shielding:

Cost-effective, requires combination with drain wire (e.g., coaxial cables).

Composite Shielding:

Copper braid + aluminum foil, full-band anti-interference (e.g., military MIL-C-17 standard).

Grounding Shielding:

Resists EMI, ensures grounding safety, enhances signal stability (e.g., coaxial cables).

Polypropylene Rope:

Lightweight, maintains cable roundness (filling rate >90%).

Water-Blocking Yarn:

Absorbs water and expands to prevent longitudinal seepage (essential for submarine cables).

Fiberglass Reinforced Tape:

Enhances tensile strength (e.g., ADSS fiber optic cables).

Why QL-Custom is trusted by many customers

Contracted Manufacturer since 1997. Till today, QL-Custom has dealed with U.S. and Europe 312+ customers !

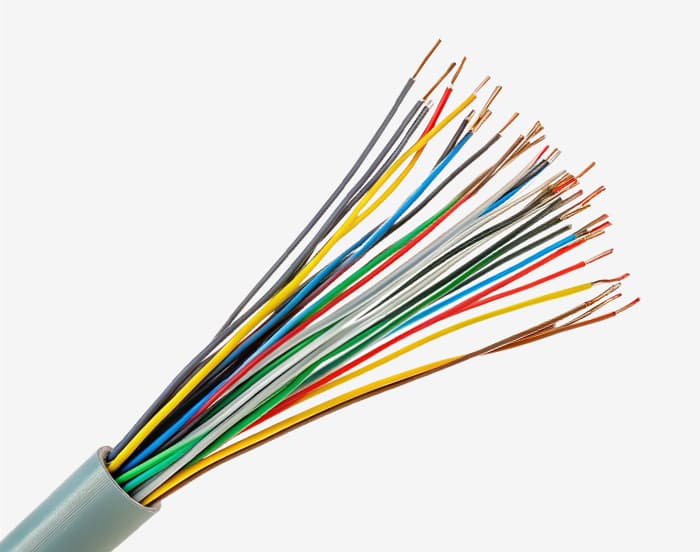

Customized wire and cable services

Customized wire and cable services offer tailored solutions to client demands, ensuring precise alignment of specifications, performance, and materials for high compatibility, rapid response, and risk-free operation, enhancing efficiency, safety, and adaptability across diverse applications.

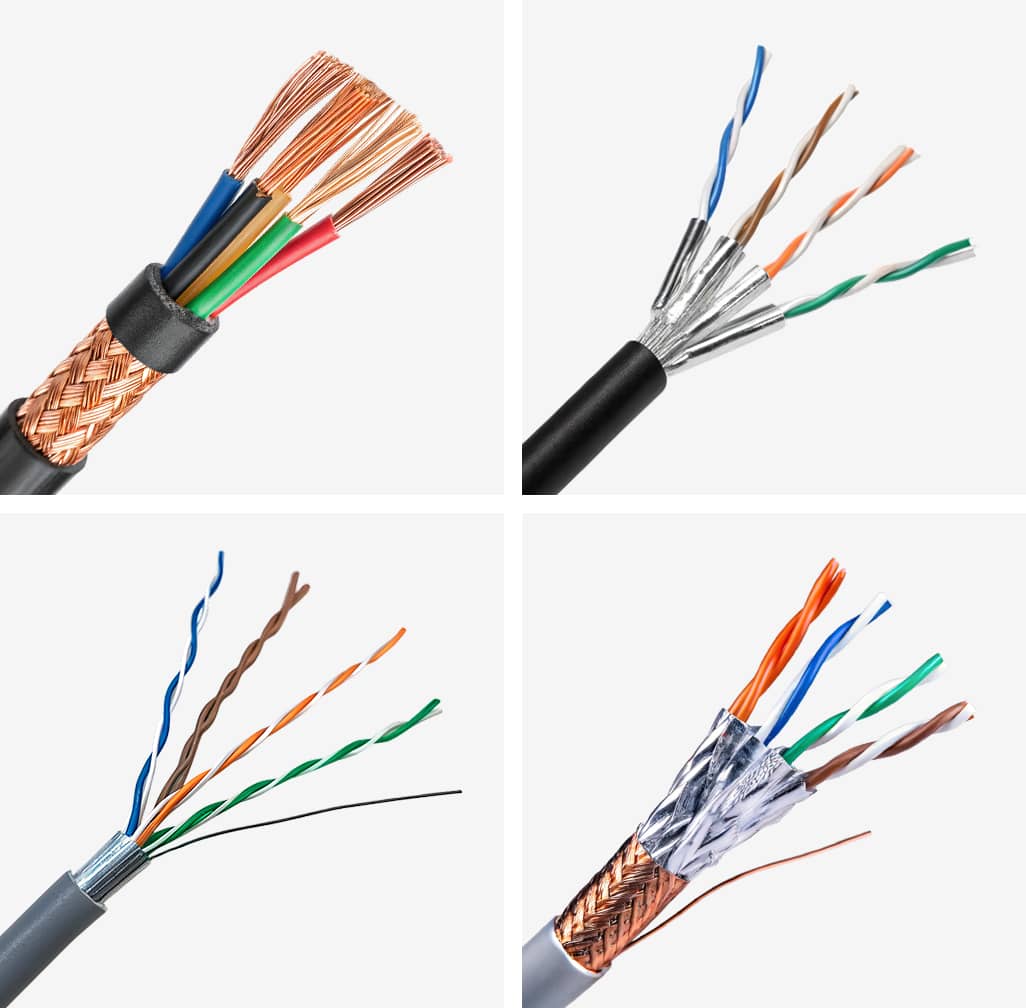

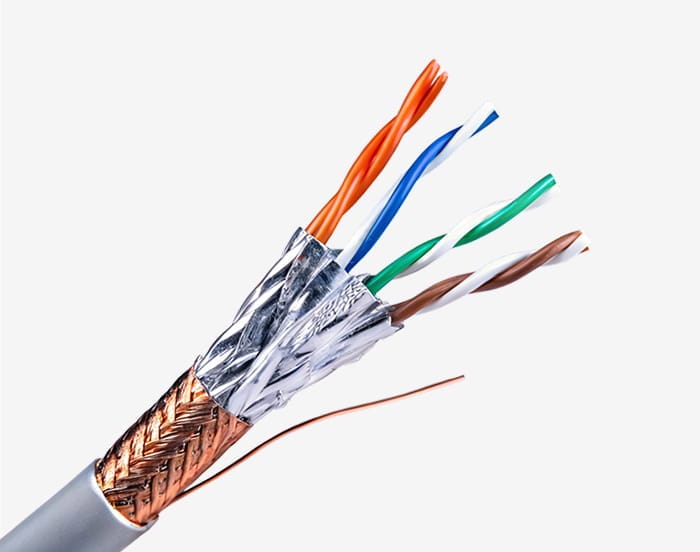

Shielded wire and cable scheme

Custom shielded cables utilize high-efficiency shielding structures to block electromagnetic interference, ensuring stable signal transmission. Ideal for precision instruments, industrial and communication applications, with tailored designs and material、EMC optimization support.

Low smoke halogen-free (LSZH) material

Custom cables adopt LSZH materials with low smoke emission, zero toxic gases, and high flame retardancy, enhancing personnel and equipment safety during fires. Complies with strict environmental standards, backed by stable material customization and technical support.

High temperature resistance

Custom cables employ heat-resistant materials (e.g., XLPE, ceramizable silicone rubber), maintaining stability under extreme temperatures with anti-aging/anti-softening properties. Suitable for metallurgy/chemical industries, supporting customized thermal management solutions.

Terminated Service

End-processing solutions for cables: precision crimping and welding services for terminal connections.

Oil, UV resistant

Custom cables feature oil,UV-resistant outer layers to withstand corrosion and UV degradation, ensuring durability in outdoor/oilfield/industrial environments. Combines safety with adaptability to diverse requirements.

Custom wire and cable advantage products

CMP fire-resistant wire and cable

Dragchain wire and cable

Microwave Coaxial cable

Ultra Flex cable

Low loss wire and cable

CAN Data cable

Ultra Thin cable

High Speed Transmission Cable

Custom Wire and Cable Service

Photovoltaic cables

UV-resistant; high-temperature tolerance (120°C+); suited for deserts and humid climates (e.g., Middle East, Southeast Asia).

Wind Power cables

Torsion-resistant design (360° dynamic bending); salt mist resistance (offshore wind); DNV-GL certified.

Energy Storage cables

1500V DC high-voltage resistance; low-smoke zero-halogen (LSZH); compliant with UL 1973.

Robotic cables

Super-flexible drag chain design (5 million cycle lifespan); integrated signal + power transmission.

High-Temperature cables

Ceramifiable silicone rubber sheath (1000°C fire resistance); meets BS 6387 standard.

Oil/Corrosion-Resistant cables

PUR/TPU outer sheath; acid/alkali/oil-resistant; DIN VDE 0282 certified.

Restricted cable OD

High-density materials such as TPEE, HDPE, FEP, and PEXC are adopted to reduce insulation layer thickness while maintaining voltage resistance and abrasion resistance. Higher-conductivity SPC replaces cotton fillers with Kevlar to minimize OD.

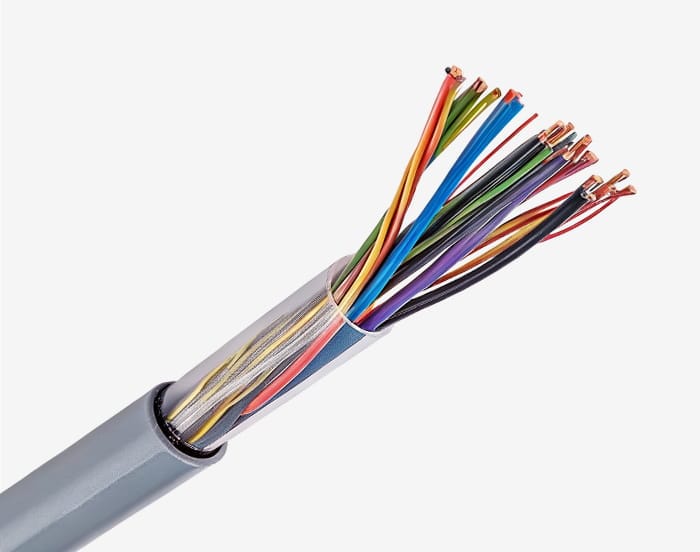

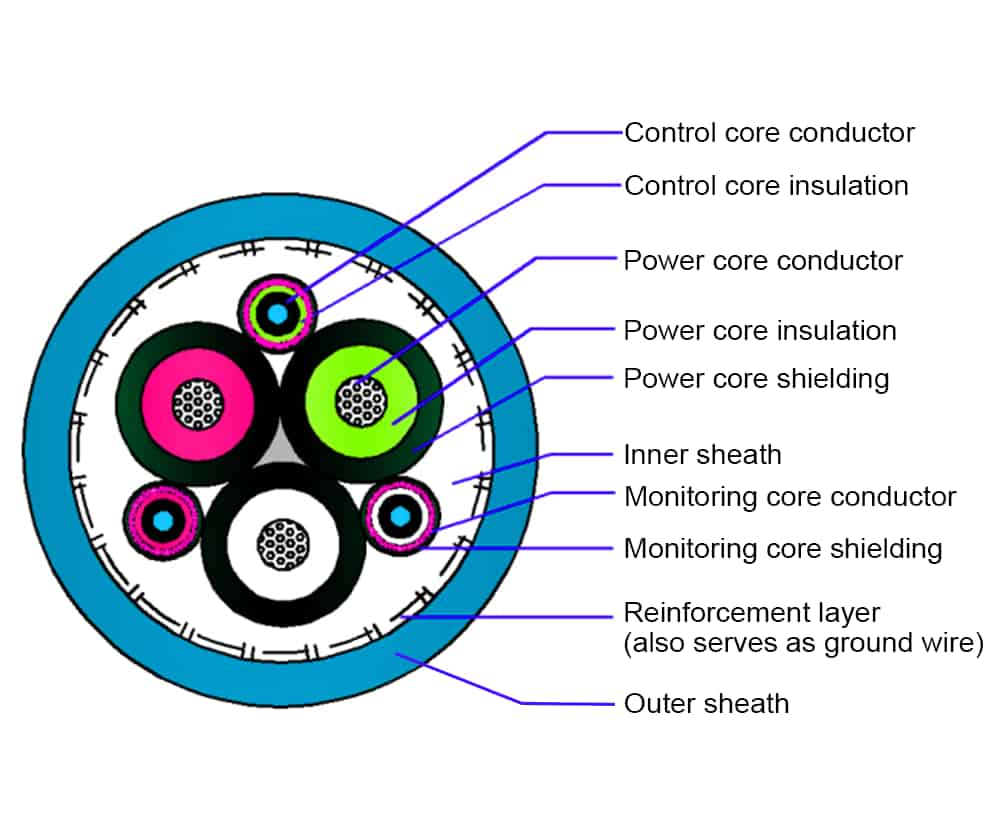

Cable in cable

Multi-functional Composite Cable combining power, signal, data, and coaxial components, with layered shielding (individual + overall shielding) for dual-layer protection.

Anti-interference Hybrid Cable

Integrates high-voltage cables and low-voltage control lines using physical isolation (separate compartments/partitions) + independent shielding to prevent crosstalk.

Shielding Solution

Braided Shielding

Tinned copper braid: 60%-95% coverage rate, shields low-frequency interference (<100MHz), resists mechanical wear.

High-density braiding (128/144 strands): Enhances shielding effectiveness to above 70dB.Foil Shielding

Full conductor coverage (100%) via longitudinal or spiral metal foil wrapping, blocks high-frequency interference (>1GHz).Twisted Pair Shielding

Strong anti-interference capability (shielding rate ≥90dB), compact design, stable signals, suited for high-frequency and complex electromagnetic environments.Combination Shielding

Foil + braid hybrid: Foil prevents high-frequency interference; outer copper braid counters low-frequency noise, achieving >90dB shielding effectiveness.

Aluminum Foil + Ground Wire Shielding: Provides full high/low-frequency protection with shielding rate ≥85dB, reliable grounding, and compact structure.

Our production workshop

Equipped with advanced facilities and a professional team, we rigorously manage each process from material selection to finished product inspection, ensuring superior cable quality that meets diverse customization requirements.

Get a Quick Quote

Our Quality Assurance

What our clients say about us !

John P., Automotive Supplier

Received UL-certified EV charging cables 3 days ahead of schedule! Their engineers even optimized the bend radius for our tight battery compartment. Most responsive Asian supplier we've worked with.

Emma W., Medical Device Co.

Precision matters for our MRI cables. They delivered IEC 60601-compliant prototypes with zero magnetic interference. Documentation was clearer than EU competitors'. Will repeat.

Hans G., Wind Energy Co. (Hamburg, Germany)

DNV-GL certified offshore cables survived our Baltic Sea tests. Modified the armor layers per our saltwater corrosion specs. Delivery met T+5 despite supply chain chaos.

Sarah L., Robotics Startup (Austin, USA)

Custom PUR cables for collaborative robots arrived in 18 days. Withstood 2M+ flex cycles in testing. Their WhatsApp support team answered 24/7 - lifesavers!

Franziska B., Industrial OEM (Stuttgart, Germany)

Precision-matched our DIN connectors. Provided complete material traceability sheets. Only 0.12% defect rate - better than local suppliers. Pricing? Fair for the quality.

Mike R., Film Studio (LA, USA)

Custom-colored stage power cables with Hollywood-spec flexibility. They actually understood 'urgent' means 72hrs. Now our go-to for film gear cabling.

Olivia T., University Lab (Oxford, UK)

Designed cryogenic cables for our quantum computing project. Tolerated multiple specification changes. IP protection agreement was professional.

Diego M., Solar Farm (Phoenix, USA)

2,000m of UV-resistant PV cables delivered to desert site. Withstood 50°C daily swings. Their logistics team handled last-mile delivery to remote location.