Business license issued by the industrial and commercial administrative organs of industry and commerce, individual operators to engage in a production and business activities of the certificate. Its format by the State Administration for Industry and Commerce unified regulations. Tax license proof that QL-Custom company is a legal company and all incoms are reasonal.

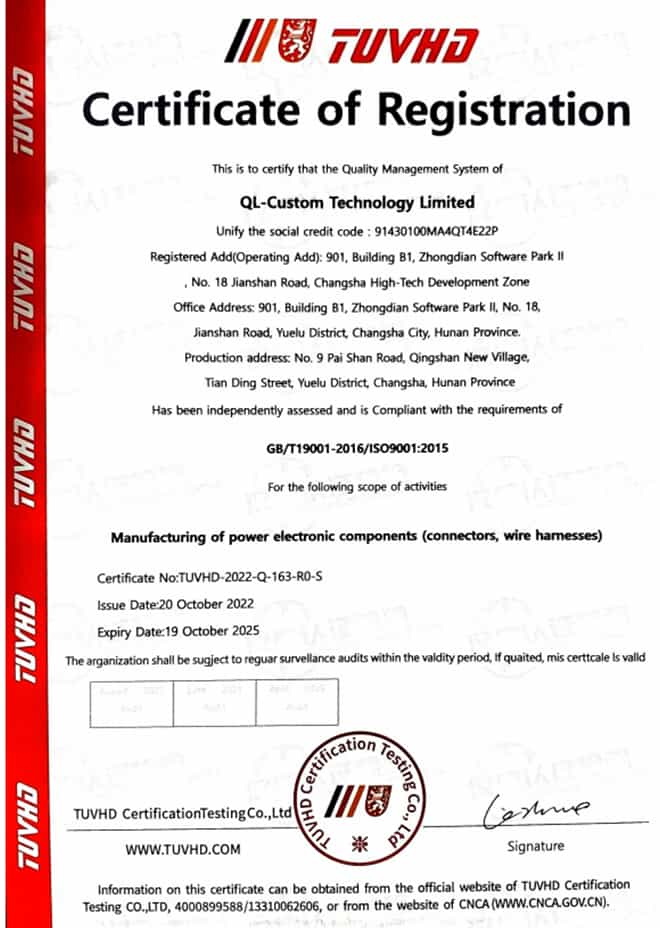

ISO9001 is used to demonstrate the ability of an organization to provide products that meet customer requirements and applicable regulatory requirements, with the aim of increasing customer satisfaction. In accordance with the practice of international economic cooperation and technological exchange, the two sides must have a common language, a unified understanding and a common standard in the quality of products (including services) before they can cooperate and communicate. ISO certification quality management system certification just to provide such a trust, is conducive to the quickly reached an agreement between customers and us.

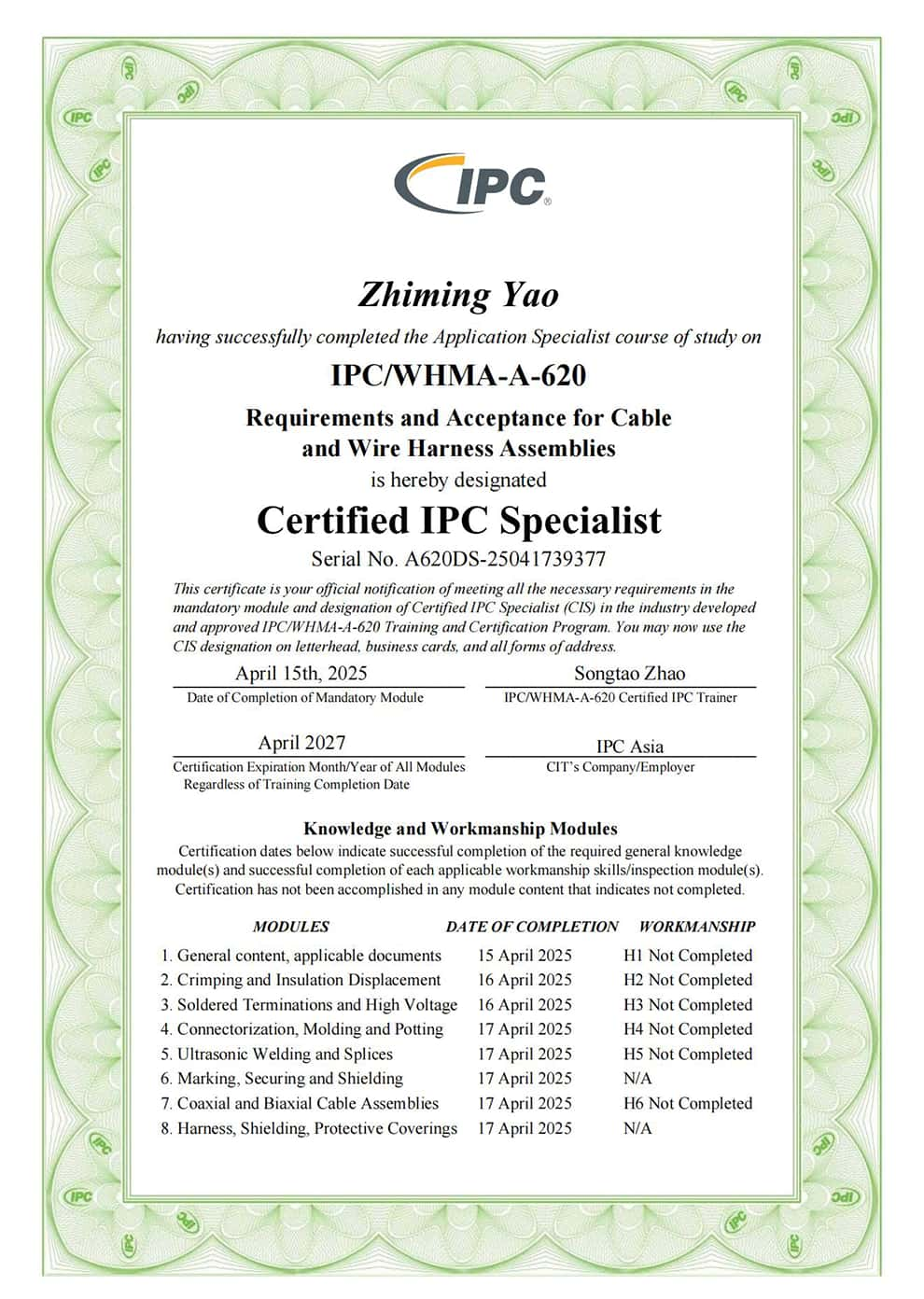

IPC620 is a North American Wire Harness Manufacturer Association standard which can guide wire harness manufacturer how to gurantee a wire harness manufacturing quality. IPC620 has class 1-3 to identify accepatability of wire harness grades, we often use the most strengency grade to control our customers' cargos to gurantee our customers receive every pc are correct and meet customers' needs.

The new Directive 2011/65 / EU (ROHS 2.0) to replace the new directive 2002/95 / EC will take effect 20 days later (ie 21 July 2011).

New RoHS certificate model 2011/65 / EU Directive CE certificate model

New RoHS certificate model 2011/65 / EU Directive CE certificate model

“Effective” means the RoHS 2.0 Directive on the EU Member States from July 21, 2011 entry into force, the Member States must be July 21, 2011 to January 2, 2013 time Completion of the RoHS2.0 directive can be converted to the work of internal laws and regulations of Member States! In the July 21, 2011 to January 2, 2013 this conversion period, companies still only need to comply with Directive 2002/95 / EC.

RoHS is a mandatory standard developed by the EU legislation, its full name is “Restrictions on the use of certain electrical and electronic equipment in the instructions” (Restriction of Hazardous Substances). The standard will be July 1, 2006 began the formal implementation, mainly for the specification of electrical and electronic products, materials and process standards, making it more conducive to human health and environmental protection.

QL-Custom promise our used all conductors and metals are lead free.

The new Directive 2011/65 / EU (ROHS 2.0) to replace the new directive 2002/95 / EC will take effect 20 days later (ie 21 July 2011).

New RoHS certificate model 2011/65 / EU Directive CE certificate model

New RoHS certificate model 2011/65 / EU Directive CE certificate model

“Effective” means the RoHS 2.0 Directive on the EU Member States from July 21, 2011 entry into force, the Member States must be July 21, 2011 to January 2, 2013 time Completion of the RoHS2.0 directive can be converted to the work of internal laws and regulations of Member States! In the July 21, 2011 to January 2,2013 this conversion period, companies still only need to comply with Directive 2002/95 / EC.

RoHS is a mandatory standard developed by the European Union legislation, its full name is “Restrictions on the use of certain electrical and electronic equipment in the instructions” (Restriction of Hazardous Substances). The standard will be July 1, 2006 began the formal implementation, mainly for the specification of electrical and electronic products, materials and process standards, making it more conducive to human health and environmental protection.

QL-Custom promise our used all plastic and resins are lead free.

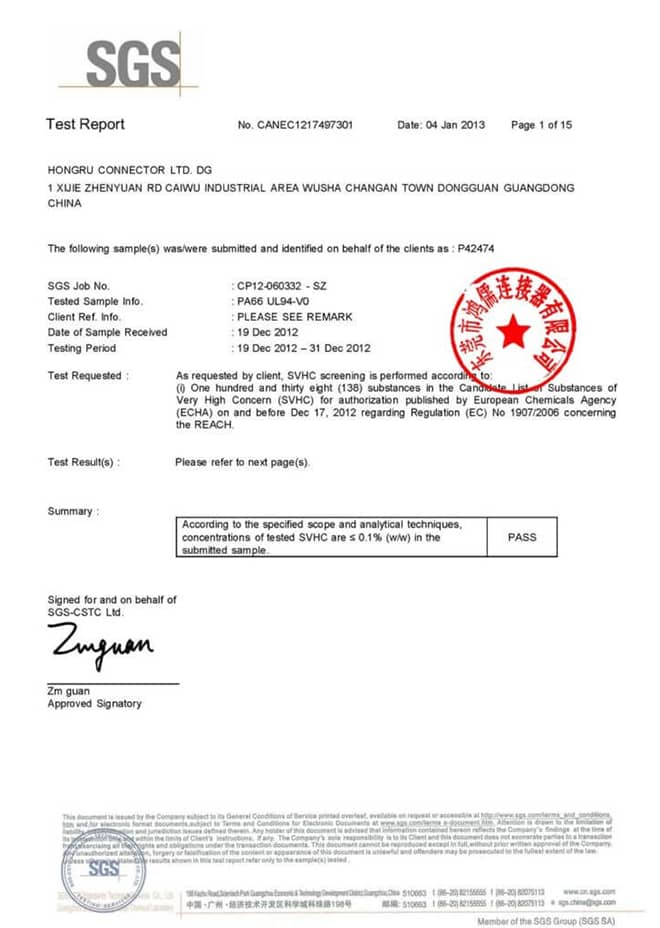

REACH is a chemical regulatory system implemented as of June 1, 2007, which is abbreviated as “REGULATION on the Registration, Evaluation, Authorization and Restriction of Chemicals”. The competent authority for this regulation is the European Chemicals Agency (ECHA).REACH regulations are extremely complex, but for Chinese manufacturers or European importers, the greater impact is their SVHC requirements. Contact us to lear more.Currently ,Reach 72 items or 138 items are used for automotive industries . Below is an example of our supplier’s Reach 138 items test report .

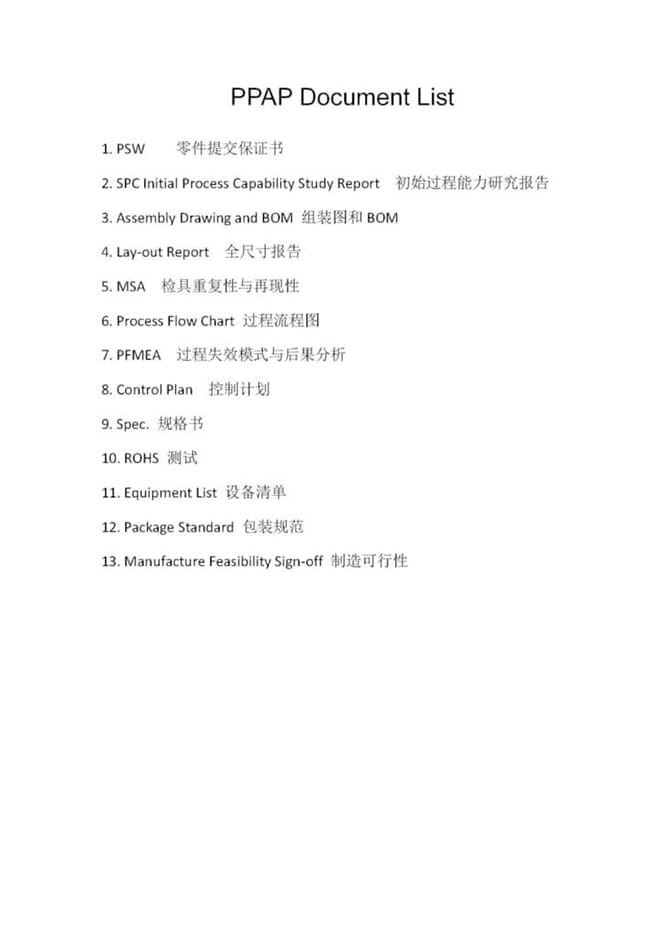

Production Part Approval Process (PPAP) specifies the general requirements for the approval of production parts, including production parts and bulk materials. The purpose of the PPAP is to determine whether the supplier has correctly understood all the requirements of the customer’s engineering records and specifications and whether the production process has the potential to meet the customer’s requirements in the actual production process. PPAP must be suitable for the supply of bulk materials, production materials, roduction parts or repair parts of internal and external suppliers on-site. For bulk materials, PPAP is not required unless requested by the customer. How to meet customer needs? How to ensure the stability of production quality? How to successfully pass the customer recognition of our products? Today’s advanced quality management philosophy is based on the process of methods, preventive measures, continuous improvement as the theme, would prefer to take the time and labor in advance from the product design, process development process to ensure product quality improvement planning to ensure follow-up production to reduce variation And waste. PPAP is usually used as the automotive industry requires the production of parts and components, requiring factories need TS certification. Below is an example of PPAP document list requested should prepare before mass production.

First digit characteristic

Degree of protection (first number in code)

Briefly describe the definition

0 No protection

1 against solid particles with a diameter of 50 mm or greater or a 50 mm diameter solid

MANN ZUG3 three anti-smart phone

MANN ZUG3 three anti-smart phone

Particles can not penetrate completely.

2 anti-diameter 12.5mm or larger particles of solid objects or 12.5mm diameter of the solid particles can not penetrate completely.

3 against the diameter of 2.5mm or more solid solid particulate matter tip or 2.5mm diameter of the solid particles can not penetrate.

4 anti-diameter of 1mm or more solid solid particulate matter tip or 1mm diameter of the solid particles can not penetrate.

5 Dust protection: does not completely prevent dust from entering, but will not interfere with the normal operation of the instrument and reduce the degree of security.

6 dust confinement: dust can not enter the object diameter of the entire shell can not exceed the gap

Second digit characteristic

Degree of protection (second number in code)

Briefly describe the definition

0 No protection;

1 anti-vertical drop of water droplets: the vertical drop of water droplets will not cause harmful effects;

2 Vertical drop of water drops when the housing is tilted up to 15 °: Vertical drop of water droplets will not cause harmful effects when the enclosure is tilted at any angle up to 15 ° on either side of the enclosure;

3 Water mist: Spray on any vertical side at an angle not exceeding 60 ° will not cause harmful effects;

4 splashing water: against the shell from any direction of splashing water will not cause harmful effects;

5 Anti-spray: against the shell from any direction will not cause harmful effects of water;

6 anti-strong water spray: facing the shell from any direction strong spray will not cause harmful effects;

7 anti-short-term immersion: room temperature and pressure, when the shell is temporarily immersed in 1M deep water will not cause harmful effects;

8 Anti-continuous soak: the manufacturers and users agree, but the conditions than 7 harsh conditions, continuous soaking in water will not cause harmful effects.

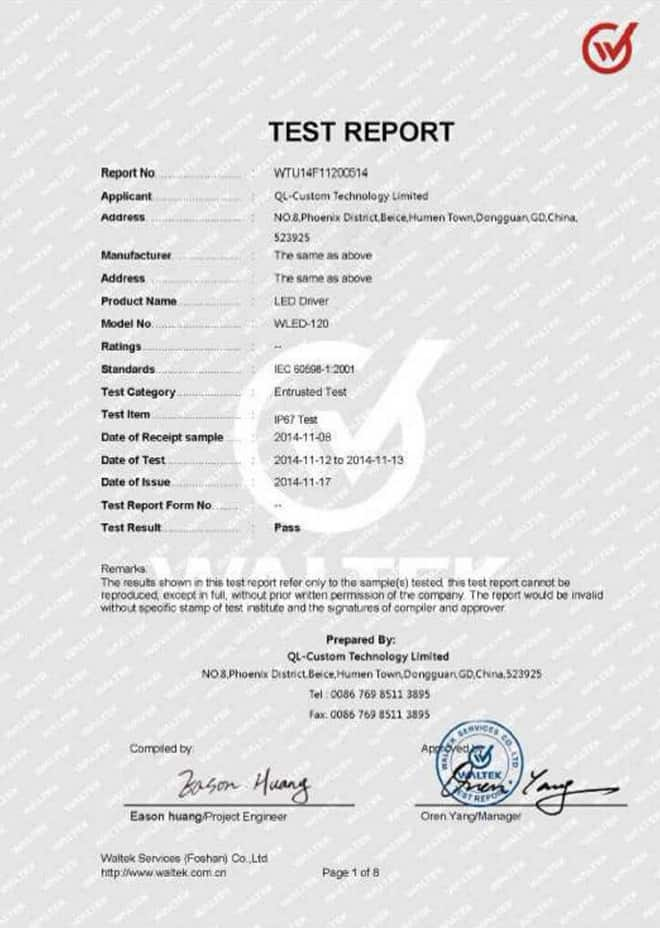

IP67 now refers to the protection level of the electronics industry IP is the ingress Protection Rating (or International Protection code) abbreviation, which defines an interface on the liquid and solid particles protection. IP followed by two digits, the first one is the dust protection level, the range is 0-6, respectively, from large foreign particles to dust protection; The second is the liquid level of protection, the range is 0-8, respectively, said Protection from vertical water drops to bottom pressure. The larger the number, the greater the ability. IP67 explanation is that protective dust inhalation (overall to prevent contact, protective dust penetration); protection of short immersion (immersion). At present in the wiring industry is the highest IP67 level. In addition, the industrial connector temperature, engage in seismic and other harsh environment considerations.

This report demonstrates that QL-Custom has the full capability to design high-water-proof molding and cabling products.

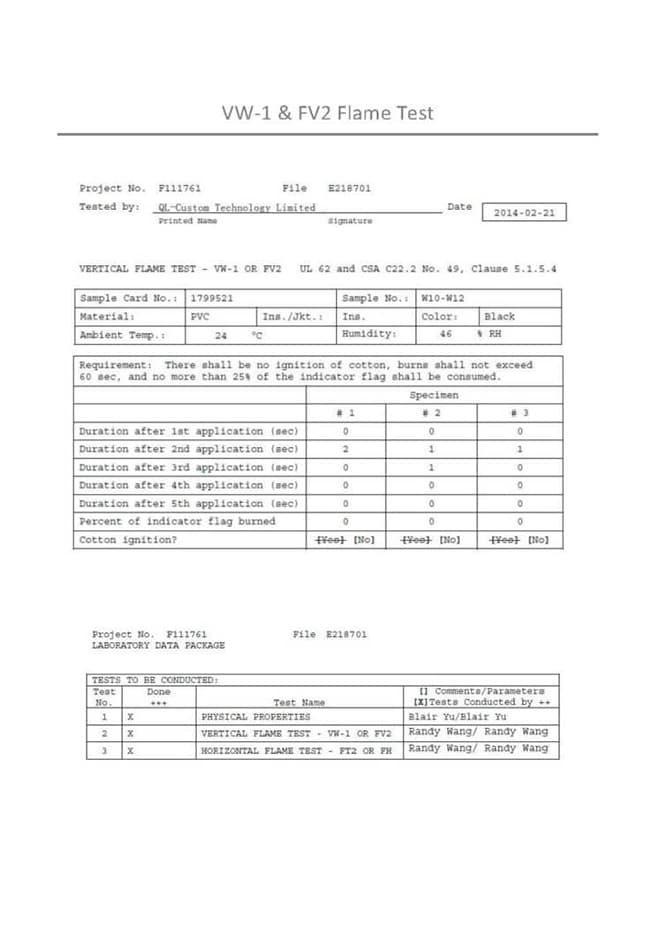

UL94 There 12 levels:

HBM, V-0, V-1, V-2, 5VA, VTM-0, VTM-1, VTM-2, HBF, HF1, HF2 for foam materials Level test program is as follows:

1) HB: Horizontal Burning Test

2) V0-V2: Vertical Burning Test

3) 5VA / 5VB: 5V 500w (125 mm) Vertical Burning Test

Use application:

– This standard applies to equipment and electrical parts of the plastic flammability test

– The final acceptance of the material depends on its use in the overall plant and in accordance with the standards applicable to the equipment

– This standard can be used for other non-metallic materials; but does not apply to building materials and decorative plastic materials

– The methods described in this standard include standard size samples and are only used to measure and characterize the flammability of materials used in equipment and electrical appliances relative to heat and flame in controlled laboratory environments

Qualified Analyze:

UL94 HB: Horizontal combustion

The plastic burns slowly but does not extinguish itself. This type is the lowest level of UL, often with vertical V0, V1 or V2 approach does not work when using this method.

UL94 V0, V1, V2, 5V: vertical combustion

UL94 V0 Method of assessment: After the flame has been removed after ignition, the sample can be self-extinguished rapidly to within 10 seconds of no burning of the melt (ie, the burning of the melt is located one foot below the test sample Cotton pad, can not ignite cotton).

UL94 V1 evaluation method and V0 similar, but it requires a longer self-extinguishing time. This test allowed the melt to drip onto the cotton pad, but not the cotton.

The UL94 V2 is the same as the V1 except that it allows the burning droplets to ignite cotton below one foot.

UL94 5V is the most stringent detection method, it relates to the actual plastic products in the flame life. The test required a flame length of 5 in. Five burns were applied to the test specimen. No droplet dripping was allowed during the test. The test sample was not allowed to distort significantly and no burnt holes could be produced.

In order to make our customers trust us more, we will continue to update our frequently asked questions and knowledge, so that customers can learn more from our blog. And customers together progress, get a win-win situation.

Read MoreQL-Custom Technology Limited is an ISO9001:2015 professional company that specializes in Custom made Over molding cable assembly and wire harness. If you are looking for the best partner in plastic molding, low pressure molding (PCB over molding) and wiring, then you have finally come to the right place where you will be served by a highly experienced and competent team – leaders in the industry. We manufacture high quality parts that are used in a wide rang...

Read More