Are there Benefits of Custom Plastic Injection Molding

Machines have lots of little parts. Some of these parts are made of plastic. People use a big machine to melt plastic and press it into a shape to make plastic parts. This is called Custom Plastic Injection Molding! Plastic moulding helps make parts the same size and shape every time. That way, every part fits just right. It also costs less than making parts by hand. Plastic parts made this way are strong and last a long time. Let’s learn why plastic moulding is so helpful! How Do We Make Plastic Pieces That Fit Together? Plastic pieces need to fit together like a puzzle! They cannot be too big. They cannot be too small. They need to be just right! Plastic injection moulding makes every piece the same shape and size. This means no mistakes! No wobbly parts! Every piece will match and work perfectly, just like magic! Factories use this method to make substantial plastic parts for many things, like toys, machines, and cars. Custom Plastic Injection Molding: Make So Many Pieces Making plastic pieces this way helps save lots and lots of money. First, we make a unique mold. Then, we can use it repeatedly to make thousands, even millions, of pieces! We do not have to wait a long time for each one. We can make so many pieces super fast! This also means we do not waste extra plastic, and that helps save even more money. Less waste is better for the earth, too! Strong and Tough Plastic Pieces That Last a Long These plastic pieces are not weak! They are powerful! They do not break easily. They do not melt when it is hot. They do not crack when it is cold. They stay in good shape for a very, very long time! That...

Read More »Benefits of Using a Custom Wire Harness in Electronics

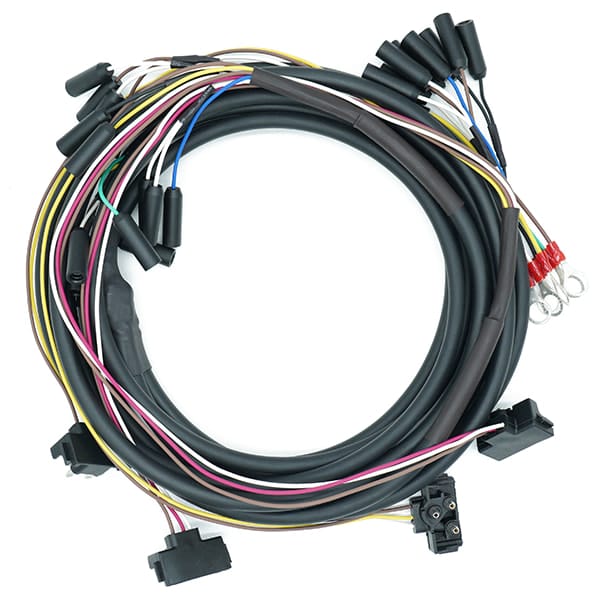

Wires are tiny ropes that carry power to machines. When wires are all over the place, they get messy and can break. If a wire breaks, the machine may stop working. That is bad! A Custom Wire Harness is a way to keep wires safe. The wires stay in one place and do not get tangled. That means machines can work better and last longer. It also helps people stay safe. Let’s learn why wire bundles are super helpful for machines. A Custom Wire Harness Helps People Save Time A wire harness bundle is a bunch of wires in one neat and tidy group. When wires are all loose, they can get messy and complicated. But they stay nice and neat when they are in a wire bundle. This makes it so much faster to set things up. People do not have to guess where each wire goes because everything is already in the right spot. It also helps to stop mistakes. If the cables are not mixed up, everything will work just right. That means no problems, no worries, and no time wasted! Custom Wire Harness Keeps Wires Neat If wires are loose, they can turn into a big, big mess. They can twist, tangle, and get all mixed up. That makes it hard to know which wire goes where. A wire bundle stops this from happening. It keeps all the cables in one place, all neat and tidy. This makes it so much easier to work with. It also helps if something breaks because people can find the correct wire fast. No more guessing or searching—everything is right where it should be! Custom Wire Harness Keeps Wires Safe from Water Wires need to stay safe to work the right way. They can break if wires get wet, dirty,...

Read More »How do OBD Cables help troubleshoot vehicle problems

OBD cables are tools to help cars. They connect the vehicle to a machine. This machine finds problems inside the car. It shows codes that tell what is wrong. This makes fixing the vehicle easy and fast. OBD wires save lots of time. They help mechanics fix cars quickly and satisfactorily. What Are OBD Cables and How Do They Help Your Car? OBD connectors are little plugs that help find what is wrong with your car. They are like a bridge between your vehicle and a tool that checks for problems. The car’s computer saves clues when something is wrong. The OBD connector lets the tool read these clues. This helps mechanics, or even you, know what needs fixing. It makes fixing cars faster and easier. Without this, it would take a lot more time to figure out what is wrong. How Do OBD Connectors Help Find Car Problems? Your car has a little computer inside. This computer checks if everything is working fine. If something is broken, it saves a code. The OBD plug helps read this code. When you connect the plug, the tool shows the code on its screen. It’s like the car is talking to you, telling you what’s wrong. This makes fixing the vehicle easy. It saves time because you don’t have to guess. It helps everyone, from drivers to mechanics. Why Are OBD Power Pins So Important? The OBD power pins are small parts, but they do a big job. They give power to the tool that checks your car. Without these power pins, the tool will not turn on. That means it won’t work. The pins make sure the tool has the energy it needs. If the pins are broken, you can’t read what’s wrong with the car. They may be tiny, but...

Read More »Can Technomelt Hotmelt Resins be used for automotive works

Technomelt hotmelt resins are like glue for car parts. They stick parts together very well. They can handle lots of heat and stay strong. They fill spaces and stop leaks. This helps make cars safer and better. These resins work in hard places and last a long time. They keep car parts safe and in place. What Are Technomelt Hotmelt Resins? Resins are like sticky glue. They hold things together. Hotmelt resins are robust and work well. They melt when they are heated up. When they cool down, they keep things tightly. These resins are perfect for cars. Cars have many parts that need to stay together. The parts must remain strong, even when it is very hot or very cold. They also must hold when cars move and bump around. Technomelt resins help cars stay strong and work like they should. They are super helpful for building cars and keeping parts in place. Why Are Technomelt Hotmelt Resins Good for Cars? Technomelt hotmelt resins are strong and tough. They can handle heat when it is very hot outside. They also work when it is freezing cold. Cars move a lot and shake on bumpy roads. These resins do not break or fall apart. They seal gaps to stop water, air, or dirt from coming inside the car. This makes cars quiet and more comfortable. Car makers like Technomelt resins because they work very fast. They help save time when cars are being built. These resins make cars better, stronger, and safer. How Do Technomelt Resins and Epoxy Resins Compare? Epoxy resins are strong, too. They are great for some jobs. However, epoxy resins take a long time to harden. You have to wait before they are ready. Technomelt resins are faster. They work right away when they are heated....

Read More »What are the best sectors for using Cable Assembly

Cable Assembly connects wires together. They are used in many jobs. Cars use them to power lights and systems. Planes need them to keep everything running safely. Factories use them to power big machines. These assemblies protect wires from damage. They stop problems like short circuits. They are strong and last a long time. Hospitals also use them as medical tools. Cable assemblies are helpful in many ways. They keep things safe and working right. Many industries use them every day. Electrical Power Systems: Cable Assembly Bring Power Power cables bring electricity to homes. They help lights turn on. These cables also help machines work. Without these cables, we wouldn’t have power. Cable assemblies are like tiny helpers that connect all the parts. They make sure the electricity can travel safely to our homes. These little cables help our world stay bright. Automotive Industry: Help Cars Run and Keep Us Safe Cable assy helps link everything, from the engine to the lights. These cables ensure that the vehicle can drive and that we can see it at night. Cable assemblies help keep the car working right. They also keep us safe by making sure the car’s lights, sensors, and brakes all work when we need them. Without these cables, our cars couldn’t drive or keep us safe. Industrial Equipment: Machines in Factories Work Right Big machines in factories use wire assemblies. These cables bring power to the machines. If the cables break, the machines stop. When the machines stop, work in the factory stops too. Cable assemblies are vital because they keep everything running. They help the machines work better and last longer. If these cables didn’t work, the factory couldn’t make anything. Consumer Electronics: Make These Working well Cable assy is used in our phones, TVs, and computers. These...

Read More »How does a Custom wire harness help us

A custom wire harness keeps wires neat and tidy. It stops wires from getting messy. This helps gadgets work better and last longer. A custom harness is made to fit just right. It saves space and looks clean. It also makes fixing wires easy. These harnesses are used in cars, planes, and gadgets. They keep wires safe from damage. A wire harness is a wise choice. It keeps everything working smoothly. It also makes gadgets safer to use. Neat wires mean fewer problems and a longer life for your gadget. Custom Wire Harness Helps to Makes Things Work A wire harness is like a special box for wires. It holds many wires together. The wires stay in place and don't get lost. This helps things work. You can use the harness in cars, machines, and other things. It helps everything stay neat. The wires do not get tangled. A custom wire-harness is a simple way to make sure everything works well. How Custom Wire Harness Saves Time A wiring harness is very helpful. It holds all the wires together. The cables are not messy. You do not need to figure out which wire goes where. Everything fits just right. The cables are prepared. You can start your work fast. It saves you time. When the wires are all together, the job is much easier. A wiring harness kit makes it so much faster to finish the work. How Wiring Specialties Make a Perfect Wire Harness Wiring specialities help make the best wiring harness. They make sure the wires are just right for your project. You do not need to worry about where to put the cables. A wiring harness fits your needs. It helps you do the work without mistakes. It is made for you. It is safe and easy....

Read More »What is Connector?

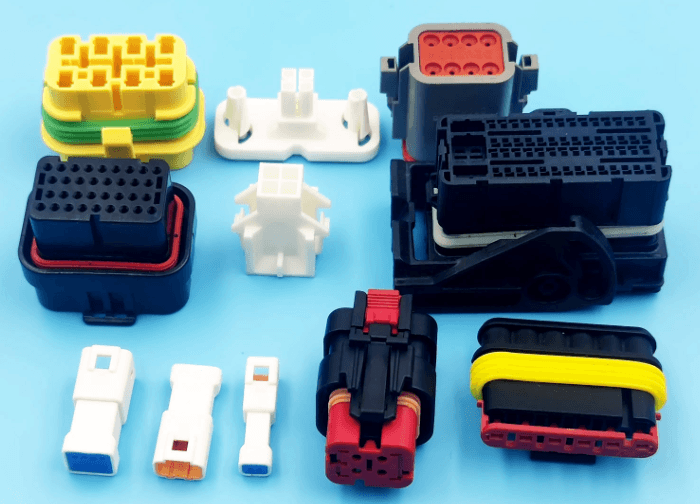

What is a Connector ? 1- Overview of Connectors Our daily lives are filled with electrical appliances,from refrigerators and televisions to hair dryers and robot vacuums, in our homes and offices. Transportation relies on electricity, powering cars, high-speed trains, and airplanes. Countless other devices and systems also depend on electrical power. These electrically powered devices and systems are comprised of intricate networks of wires and circuits, known as wire harnesses. These harnesses connect to various components and devices, and the interface points where these connections occur utilize connectors. Within these connectors, terminals play a crucial role, connecting to the conductive copper wires. Connectors, also known as plugs and sockets, facilitate electrical connections between components in a circuit or electronic device, enabling the transmission of current and signals. They simplify maintenance and repair, allowing for easy disconnection and reconnection when circuits age or malfunction. Connectors are ubiquitous, serving a wide range of purposes and significantly enhancing efficiency. 2- Use of Connectors 1. Data and information transmission 2. Power supply 3. Connecting displays and televisions; functioning in audio and video equipment 4. Mechanical connections 3- Connector' brands Popular brands TE Connectivity, Amphenol, Molex, Yazaki, JAE, JST, Hirose, Deutsch, 3M, AMP, Foxconn, Harting, Rosenberger, LEMO, Aptiv, Sumitomo Electric, Phoenix Contact. 4- China brands CJT, AVIC, Derun Electronics, Luxshare-ICT, Yamaichi Electronics, Commscope, LOTES, Kstar, and many others.

Read More »What is equal (Substitute) Connector?

What are Alternative Connectors? 1- Overview of Alternative Connectors Connectors play a vital role in wire harnesses, serving as crucial conductors that link electrical circuits. These essential components are originally designed and manufactured by Original Equipment Manufacturers (OEMs), typically located overseas. Domestic procurement often involves dealing with distributors or international websites, leading to long lead times. Furthermore, OEM connectors often carry a premium price, adding cost pressures. These factors have led to the emergence of domestically produced connectors, often referred to as "alternative connectors." Developed based on OEM product specifications, these alternatives offer near-identical dimensions and performance, differing primarily in brand and manufacturing location. The availability of alternative connectors not only reduces costs and shortens lead times but also fosters market competition and technological advancement. They are a product of market demand, fulfilling essential functional requirements while providing consumers with greater choice and value. 2- Methods for Finding Alternative Connectors 1. Some online platforms offer alternative part number lookup functionality. You can input the part number you want to replace, navigate to the specification parameters, select the relevant data to match, and click search to find suitable alternatives. 2. If no alternatives are available on the platform, you can search for the OEM part number on distributor websites. These sites often provide datasheets with detailed specifications. Download the datasheet and inquire with domestic connector suppliers about potential alternatives with similar dimensions and specifications. 3. If a suitable alternative with similar specifications cannot be found, consider using other connector types or alternative solutions. When choosing an alternative solution, consider the actual needs and usage habits. 3- Advantages and Disadvantages of Using Alternative Connectors Advantages: Cost and Service Advantages: Due to lower labor costs in the domestic market, domestic connector manufacturers are competitive in...

Read More »What is Tyco connector, the types,prices?

What is Tyco (TE) Connector ? Tyco Electronics, now known as TE Connectivity, is a global leader in manufacturing connectors and sensors. TE's connectors are widely used in industries like automotive, industrial equipment, consumer electronics, and energy. They provide reliable data, power, and signal transmission solutions. Tyco (TE) Connector Series TE Connectivity offers a wide range of connector products for various applications, see below screenshot: Including but not limited to the following series: AMP SUPERSEAL Series: Designed for waterproof applications, these connectors meet IP67 standards and are commonly used in automotive and industrial equipment. AMPSEAL Series: Provides robust environmental sealing, suitable for electronics in harsh environments. HVA Series: High-voltage connectors widely used in electric vehicles and new energy systems. Waterproof Connectors in Automotive Application TE's waterproof connectors, especially from the AMP SUPERSEAL and AMPSEAL series, are often used in critical parts of vehicles: Engine Bay: Connects the engine control modules and sensors, designed to handle high temperatures and humidity. Chassis Systems: Suitable for sensors in suspension and braking systems, protecting against mud and water intrusion. Lighting Systems: Used for headlights and external lighting, ensuring waterproof performance. Lead Times & QL-Custom's Advantages Standard TE connector lead times can stretch over several weeks, particularly for high-demand models. QL-Custom can reduce delivery times by: Partnering with local large distributors for better inventory and faster responses. Pre-stocking materials to avoid supply chain delays. Leveraging a broad supply chain network to source and deliver parts efficiently, preventing stockouts. Pricing & QL-Custom's Price Advantage TE connector prices vary based on model and order volume. QL-Custom offers competitive pricing due to: Long-term partnerships with large distributors that grant bulk purchasing discounts. Pre-purchasing materials at lower market prices, locking in better costs. Access to a wide supplier network, enabling...

Read More »What is Switchcraft connector, the types, series, prices?

What is a Switchcraft Connector ? Switchcraft connectors, manufactured by the American company Switchcraft, are a series of connectivity products known as the industry benchmark for superior product lines. They are a leading supplier of components for various sectors, including audio-visual, medical, military, home appliances, and telecommunications. What are the different series of Switchcraft connectors? Audio connectors, including XLR connectors, sealed XLR connectors, XLR panel-mounted connectors, and XLR cable-mounted connectors. These are primarily used in professional audio equipment and musical instruments, providing stable and reliable connections for audio signal transmission. RF connectors, including MicroBNC connectors, DIN 1.0/2.3 connectors, and BNC connectors. These are primarily used for video signal transmission and are also commonly used in instrumentation equipment for high-frequency signal transmission. Modular panel connectors, including the NH series narrow panel mount connectors and the EH series. These connectors feature flexible design and various configuration options, suitable for a wide range of standard panel mounting applications. Harsh environment connector series, including sealed waterproof signal connectors, sealed circular connectors, and cable sealing glands. These are often used for sealed power connectors or multi-pin signal connectors in applications such as outdoor communication base stations, power transmission, industrial automation, and aerospace. What are the key features of Switchcraft connectors? Extensive product range: Diverse connector types cater to various connection needs, allowing users to select the appropriate model based on specific equipment requirements. High-quality materials and construction: Switchcraft connectors utilize high-quality metals and plastics to ensure robust mechanical properties and durability. Stringent manufacturing processes ensure high dimensional accuracy, contributing to long-term reliability. Stringent quality certifications: Switchcraft connectors adhere to industry standards and regulations, including RoHS, UL, CSA, VDE, and IP68, meeting safety and environmental requirements in various countries and regions. Excellent electrical performance: Featuring...

Read More »