How Automotive Wire Harnesses Have Changed Over Time

By Tina / 2025年4月20日

Cars use Automotive Wire Harnesses to move power from one place to another. This power helps make lights shine, engines run, radios play, and many more things work. We call these wires a wire harness when they are put together safely and tidily. A wire harness keeps everything working smoothly and safely. It stops wires from getting messy or breaking. It also makes it easier to fix or change things later. Every part of your car that needs power or talks to another part uses a wire harness to work.

QL-Custom Technology Ltd. is very good at making these wire harnesses. Our team is competent, skilled, and always follows safety rules. We use new tools and machines to make our products even better. We send our harnesses to many parts of the world. Our harnesses are used in cars, robots, hospital machines, cameras, and more. We constantly check our work to ensure it is strong, safe, and lasts long. People trust us because we care a lot about doing a good job.

How Automotive Wire Harness Began in Cars

In the past, cars were much simpler. They had very few parts that needed power. The wires were thick and had no colors. There were no labels or tags to help. This made it hard to fix things when wires broke or got mixed up. People often had to guess which wire did what.

Each car company used different kinds of Automotive Wire Harnesses. This meant it was not easy to make or repair cars. But cars did not have many extra features, so this was okay for a while. As more things like radios, air conditioning, and safety lights were added, cars needed better wires and better ways to organize them.

Automotive Wire Harnesses Got Better

As cars grew more complex, they needed more and better Automotive Wire Harnesses. New wire harnesses used different colors to tell wires apart. This made it easier to fix or replace them. Covers were added to protect wires from heat, cold, water, and dust. This helped wires last longer and stay safe.

Clips were used to keep wires from moving too much inside the car. This stopped them from getting loose or breaking. Later, the painless wiring harness was made. This was a big step forward. It made it easy to take out and put in wires. People could now fix things quicker and spend less money. This also made cars work better and safer. Mechanics and car builders liked this new harness because it saved time and worked well.

Smart Cars Need Automotive Wire Harnesses

Computers helped run the engine, lights, and more. Computers need harness to send and get messages. So, a new way called the CAN bus was made. It helped Automotive Wire Harnesses talk to each other faster and better. Now, cars can do more things with fewer wires.

The engine wiring harness had to do more jobs. It had to send power and messages at the same time. This meant wires had to be very strong and very smart. They had to stay connected all the time and never make mistakes. Cars became smarter, and so did the wires inside them.

Today’s Wire Harnesses

Today, cars are full of innovative tools. They have GPS, cameras, warning lights, and touch screens. All these tools need power and data. That means cars need good harnesses. Today’s wires are small, light, and very strong. They do not break easily. They can handle hot and cold weather. They also resist water and dirt.

At QL-Custom, we make smart and safe harnesses. Our wiring harness kits are made to fit perfectly. We test each harness to make sure it works right. Our harnesses work in all kinds of cars, including electric and hybrid ones. We ensure our harnesses are ready for any weather or place.

We only use the best parts. We label every harness clearly. This helps with repairs later. Our team always looks for ways to make things better. We want each harness to be clean, safe, and strong. Our job is to build the best wire harnesses for any need.

Smart Automotive Wire Harnesses Available

Forklift Engine Harness

This group of harnesses is made for forklifts. It helps all the forklift parts talk to each other. It connects lights, the engine, and more. It works in tough spots where there is lots of dust, heat, and noise. The wire is wrapped tight so nothing breaks. It is made for challenging jobs and long hours. It helps forklifts do their work well every day.

Sensor Pigtails

These short wire harnesses are made for sensors. They are great because they are easy to test and replace. When something goes wrong, you can switch them out fast. They help keep machines working without stopping for a long time. They make work easier by saving time.

ISO Wire Harness

This is for car radios and music parts. It fits lots of car brands and models. You do not have to cut or tape wires. Just plug it in, and it works. It helps car owners and music lovers get great sound fast. It is very easy to use and saves time when setting up sound systems.

Oil Gas Sensor Wire Harness

This is made for machines in the oil and gas world. These places are rough, with heat, dirt, and danger. But this is strong and safe. It keeps the signals moving and helps the machines do their job right. It’s a good pick for hard places where safety is a must.

ECU Tuning Wire Harness

This helps improve how a car’s engine works. It connects smart car parts and helps them work better together. It helps make the car faster and smoother. It is excellent for people who want their vehicles to run the best they can.

What QL-Custom Technology Ltd. Does

At QL-Custom, we help you from start to end. First, we talk about what you need. Then, we design the harness. We make a sample for you to check. After that, we build the whole order. We test every Automotive Wire Harness before we send it. Then we ship it fast to you.

We make harnesses for cars, robots, hospital tools, and more. We check every product for fire safety, water safety, and strength. We only send out the best. Our workers use clean, modern spaces. We buy only from good vendors. We always keep parts ready so we can work fast. Our team knows how to manage big and small projects. You can trust us to do the job well.

How We Build Automotive Wire Harnesses

We use intelligent machines to make wire harnesses. These machines cut, strip, and connect wires quickly. They make sure everything is the right size and shape. This helps us make electrical harnesses that are neat and strong. The machines also help reduce mistakes and save time.

Our team members are also very skilled. They work on special orders and check each harness by hand. They make sure every harness is perfect. We also use EDM tools to build small parts. This helps us make engine harnesses that fit just right.

We take our time to check every step. We also test our harnesses in many ways. We test them with heat, cold, and water. We do this to make sure they will work well in any place. We want all our products to be safe and last a long time.

What’s Coming Next for Automotive Wire Harness?

Cars are changing very fast. Some can park by themselves. Others can drive on their own. Cars can now talk to phones and other vehicles. This means harnesses have to be even better. They have to be smart, small, and fast.

In the future, wire harnesses will send more data. They will use less energy. Some will even tell you when there’s a problem. This is the future of the universal automotive harness. These new harnesses will help make cars better, safer, and easier.

At QL-Custom, we are ready for these changes. We always learn new things. We use the best tools and care about the earth. Our harnesses are made to last and be safe for nature. We want to grow and improve in innovative ways.

Why Choose QL-Custom?

- Have a kind and brilliant team

- Love what we do, and it shows

- Use only the best parts

- Test every harness many times

- Send your order fast

- Care about your needs

Old cars had only a few wires. New cars have many. These harnesses help everything work, from lights to engines.

QL-Custom Technology Ltd. builds strong and smart harnesses. We listen to you and work hard to give you what you need. We make great harnesses and send them to you fast. We are your best partner for automotive wires.

FAQs

What were early wire harnesses like?

Long ago, cars had only a few wires. These wires powered simple things like lights or horns. The wire harness was small and manageable because vehicles did not have many features.

What changed over time?

More wires were needed as cars added new parts like radios, electric locks, and seat heaters. So, wire harnesses became more complex in carrying power and signals to all the new parts.

Do electric cars need more?

Yes. Electric cars have big batteries, lots of sensors, and bright screens. These need many wires. The wire harness in these cars must be strong and safe.

Are harnesses smarter today?

Yes. Some harnesses can even check if a wire has a problem. They send signals to the car’s computer to help find issues quickly.

Will they change more soon?

Yes. As cars get better, wire harnesses will too. In the future, they may be even smaller, lighter, and smarter than they are today.

People Also Ask

What is the main point of an automotive wire harness?

An automotive wire harness are some wires that work as a group. These wires help carry power and small signals to many car parts. It helps in many ways.

Why did cars start using wire harnesses?

Long ago, cars were simple and didn’t need many wires. But when cars started getting radios, heaters, fans, and more lights, they required more wires to run all these parts. Loose cables were easy to break and could be a big mess. So, wire harnesses were made to keep wires together.

What was the wire harness making process in the past?

People had to cut the wires and wrap them without machines. The cables were not very strong, and the covers around them were thin. They could break if it got too hot or if water got inside.

What are the differences in new wire harnesses?

Today, wire harnesses are made using strong tools and intelligent machines. That means they last longer and keep the vehicle safe.

What materials were used before?

Copper and rubber. It could melt when it got hot and crack as it got old. This made the wires easy to damage.

What materials are used now?

Today, wire harnesses still use copper inside because it is good at carrying power. But now the outside cover is made of plastic. Plastic is much stronger than rubber. It does not melt or crack as fast. It keeps water out and helps wires stay safe for many years.

What are the chances in wire harnesses?

Wire harnesses now have more wires and more jobs. They must carry more power and also take more small signals. That means the harnesses need to be smarter and better made.

Do electric cars use wire harnesses, too?

Yes, electric cars use these in many ways. It helps the car to run smoothly.

Are wire harnesses safer now?

Yes, wire harnesses are much safer now than they were before. Machines make them the right way every time. Each one is checked before it goes into a car. This helps stop problems before they happen. It keeps the car working right and helps protect people inside.

Will wire harnesses change more in the future?

Yes, wire harnesses will keep changing as cars get better. In the future, they may get smaller but still carry more power. Some vehicles use fewer wires or no wires at all. They might send signals through the air. Wire harnesses will grow and change as cars do more things.

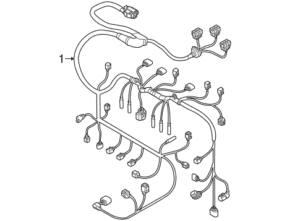

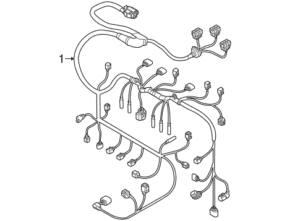

Image of Automotive Wire Harness With Diagram