Who is QL-Custom

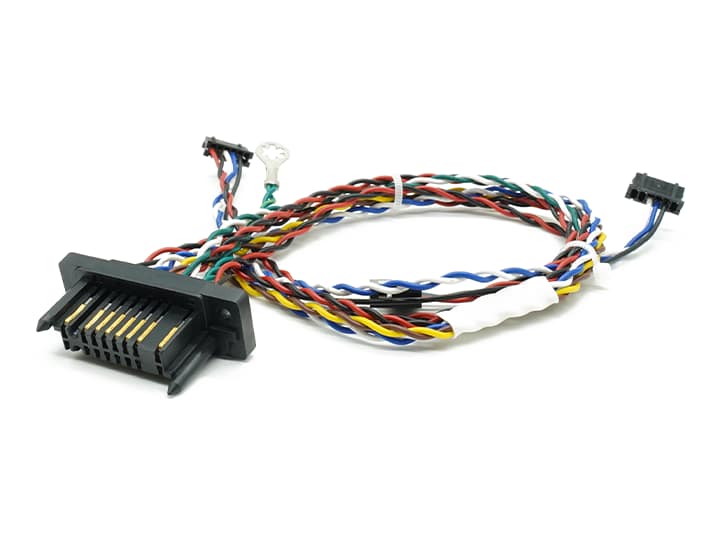

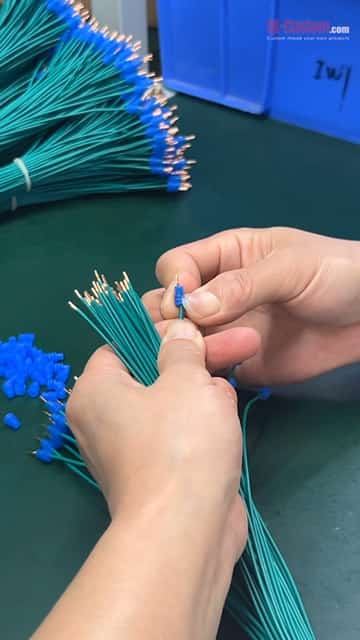

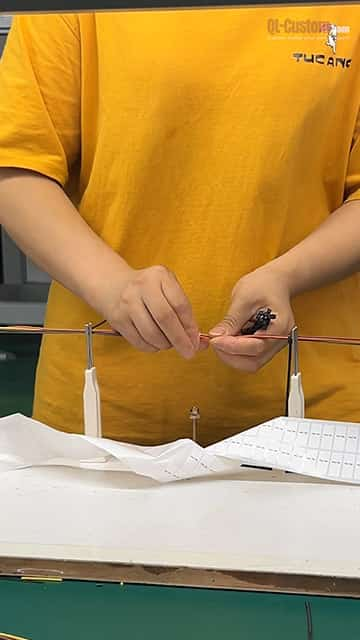

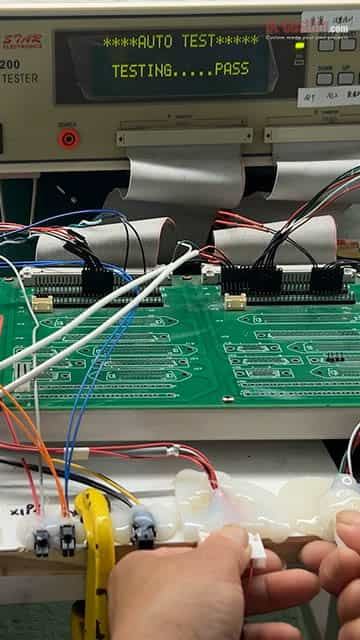

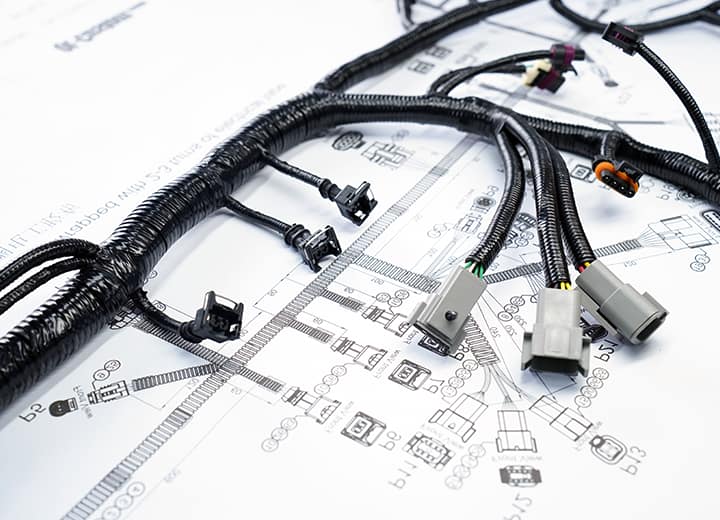

QL-Custom Technology Ltd is a Chinese wire and cable harness manufacturer based in Changsha, a central city of China. As a Custom Cable, Over-Molding Cable, and Custom Wiring Harness manufacturer in China, we provide global customers with efficient, accurate communication and professional services that help them win in their markets. We always consider and stand with our customers’ position, and maintaining market competitiveness requires us to strictly control product quality. Quality is the vitality of a company, and it is the ultimate measure of whether we are the right long-term partner for your business.

We welcome customers to visit our company. A confident and proffectional factory that can stand the test and examination.

Get a Quick Quote