QL-Custom 于 2013 年推出了全新的模具热流道系统,主要针对高价值的塑料使用,为客户节省材料成本,我们超过 4 年的热流道系统设计经验可满足客户对不同流道系统的需求,同时,经验丰富的设计和模具师傅可确保每套模具的交付,QL-Custom 还可以为客户制作所需的终端产品,这得益于我们高效的注塑生产线。

>> 什么是热流道系统模具

热流道是一种节省材料使用的成型系统,材料流道较长,更接近模腔。该系统工作时不会浪费塑料。尤其是对于一些昂贵的材料,它能节省很多材料。在大批量生产时,虽然成本高于现有的模具设计,但它还是很受欢迎。

热流道系统分为全热流道和半热流道。全热流道设计复杂,但效果好,维护成本低。半热流道结构简单、稳定、使用方便、故障率低,由于结构简单,因此维护成本低,对生产的稳定性有较大的保证。热流道分类:开放式(半热流道)、针阀式(全流道)。

>> 热流道系统装配案例研究

- 将模具平放在模具上,用风清理所有的孔和模板。

- 检查每个孔的尺寸,重点检查深度。清除模板上的毛刺。还要检查锁分水器的螺丝孔,中心钉和防针孔是否打完。这个地方对于第一次做热流道模具的师傅来说经常会漏掉。

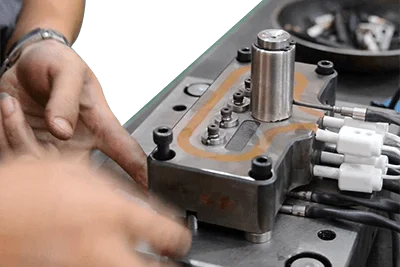

- 热口密封位和带红色模具的两个部件的阶段。

- 热翠测试设备,然后拆下检查密封位

(1)是否擦红红,楼梯位

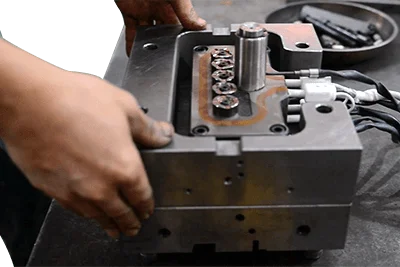

(2) 不接触模具。如果没有,停止安装,检查错误原因进行调整。确保配合紧密无漏料。此过程中应注意不要碰到尖头。 - 将所有热翠安装好,同时安装中心垫、中心销,防倾销。并在其平面上扫红。

- 检查翠平面和中心垫高,误差控制在 0.05 毫米以内。