The Wire Cable Harness Drawing Standards

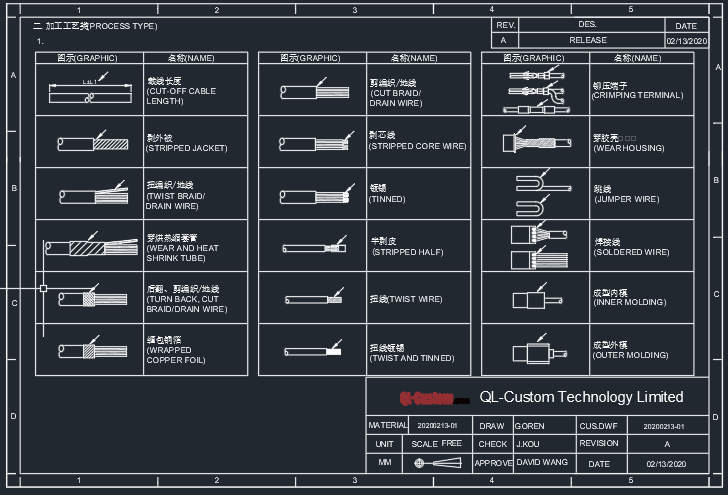

Importance of the Wire and Cable Harness Drawing In the realm of modern engineering and design, wire cable harness drawings hold paramount importance. These drawings serve as blueprints that detail the intricate layouts of wiring systems, ensuring that each component is correctly connected and functioning as intended. Without precise drawings, the likelihood of errors increases, which can lead to system failures, costly repairs, and even hazardous situations. For engineers and designers, mastering wire cable harness drawing standards is not just an option but a necessity to ensure the reliability and safety of their projects. Wire cable harness drawings are essential for several reasons. Firstly, they provide a visual representation of the electrical connections and layout, making it easier for engineers to understand and communicate the design to others involved in the project. This includes manufacturers, technicians, and quality control personnel. A well-drafted harness drawing eliminates ambiguities, reducing the risk of misinterpretation and ensuring that everyone is on the same page. Secondly, these drawings play a critical role in the manufacturing process. They guide the assembly of the wire harness, specifying the lengths of wires, the types of connectors, and the routing paths. This level of detail is crucial for ensuring that the harness fits correctly within the physical constraints of the application, whether it's in an automotive, aerospace, or industrial setting. Accurate drawings help streamline the production process, minimize errors, and enhance the overall quality of the final product. Mastering Wire Cable Harness Drawing Standards: A Comprehensive Guide for Engineers and Designers To master wire cable harness drawing standards, engineers and designers must familiarize themselves with industry norms and best practices. These standards are established by organizations such as the International Electrotechnical Commission (IEC), the Institute of Electrical and Electronics Engineers (IEEE), and the National Electrical Manufacturers Association (NEMA). Understanding...

阅读更多 "涉及哪些证书线束?

线束涉及哪些认证? 在竞争日益激烈的线束市场,产品认证和工厂认证显得尤为重要,通过专业检测机构对产品质量进行严格的质量控制,可以有效筛选出合格的产品以及优质的供应商,是对客户的一种保护。 1- 产品的 RoHS 认证 1.RoHS 认证是欧盟制定的一项强制性标准。它主要用于规范电子电气产品的材料和工艺标准,使其更有利于人体健康和环境保护。Rohs 已纳入欧盟强制性认证 CE,一般只要求提供检测报告就可以了,但如果客户需要证书,也可以出具 CE 证书。主要是针对产品的原材料进行认证。 Reach 2-Reach 只有检测报告,没有证书,REACH 认证是欧盟法规 "Registration, Evaluation, Authorization and Restriction of Legal Goods "的简称。主要针对产品的原材料进行认证。 防水 3-防水认证:首先,我们要弄清楚客户要求的是材料本身防水还是设计和制造防水,这是我们的首要任务。关于材料本身防水:材料本身防水是指连接器或电线电缆材料可以在户外使用,不会在浸水的情况下发生物理劣化。制造设计防水:是指该产品在设计和制造后,这种设计不会进水或进灰,如我们常见的应力消除设计。 UL 4-UL:美国安全实验室认证,证明产品符合美国安全标准。UL 主要针对北美地区,美国以外地区....。

阅读更多 "盘绕电缆的设计逻辑

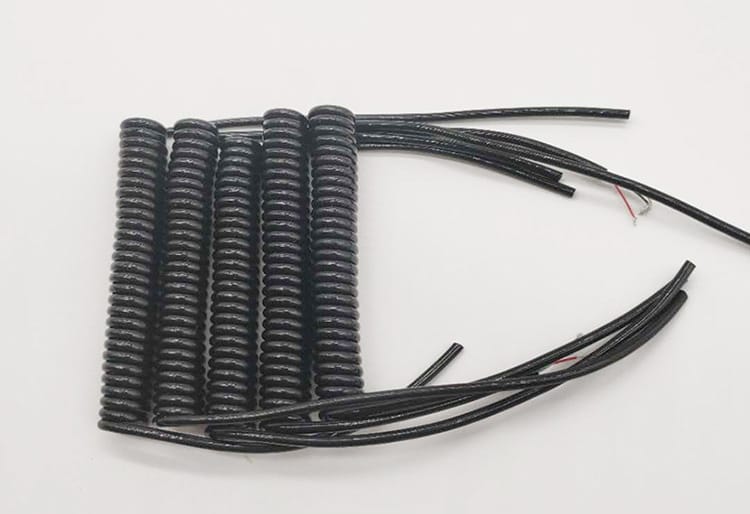

盘卷电缆的设计、制造、长度计算和注意事项 1.什么是盘卷电缆? 盘卷电缆又称可伸缩盘卷线或螺旋电缆,是一种可以像线圈一样伸缩的电缆。线圈电缆的原型实际上是直电缆。直电缆通过绕线缠绕在固定尺寸的夹具杆上,两侧的夹具用于夹紧电线。然后将其放入烤箱烘烤一段时间。取出后形成线圈电缆。 2.计算线圈电缆的实际长度 1.确定结构: 了解组成盘绕电缆的盘绕部分和直线部分的数量。 2.测量线圈参数: 线圈长度:我们需要清楚卷绕部分的长度,从一 pc 卷绕电缆 L=350mm 线圈内径:测量卷绕部分外径=15mm 这个参数决定了夹具棒的外径 线圈外径:测量卷绕部分外径=25mm 电缆外径:测量电缆外径5.0mm 然后我们就可以算出电缆卷绕部分有多少线圈。使用线圈部分长度/电线外径 350/5.0=70 个线圈 计算 1 个线圈长度 = πD= 3.14 X (25mm-5.0mm)=62.8mm (因为我们不能使用最大外径来计算圆周率) 1 个线圈 62.8mm X 70 个线圈 = 4396mm+ 两端长度即为 1 pc 电缆的实际长度 注意,测量方法相对简单直观,但可能会有一些误差。公式计算法需要精确测量盘卷电缆的结构参数,计算结果只是近似值。在实际计算中,请根据具体情况选择合适的方法。 4.计算公式...

阅读更多 "