Superior Custom Wire Harness for the right Job

By Tina / 2025年3月28日

The custom wire harness connects machine parts while keeping wires organized and secure. It ensures electrical components function smoothly. Regular cables can be messy. They get tangled and break easily. A custom harness is made for a specific job. This helps machines work better and last longer. It also enhances safety, which is why industries like automotive, aerospace, and heavy machinery depend on them.

Wire harnesses come in various sizes, lengths, and coverings to keep wires securely in place. This stops them from moving or tangling. Keeping wires neat helps air flow better. It also reduces heat. This makes machines work more smoothly. Wire harnesses are used in homes and factories. They keep electric connections strong and safe. Engineers use them to enhance the safety and maintainability of electrical systems.

QL-Custom Technology Ltd. manufactures high-quality wire harnesses. Our products are safe and high quality. Many industries trust us. We test every harness to make sure it is the best. We always look for new ways to improve. Our team works with customers to make the right products for them. Our harnesses are easy to install. They last a long time and work well.

Why Choose Us for Custom Wire Harnesses?

QL-Custom Technology Ltd. is ISO9001:2015 certified. This site is expert in custom wire harnesses. QL-Custom also makes over-molding cable assemblies. Our team has many years of experience.

Our products are trusted by the electronics, medical, automotive, robotics, military, clean energy, and camera industries. Our team focuses on innovation, quality, and customer happiness. If you need a custom wire harness, choose us!

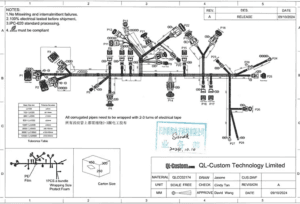

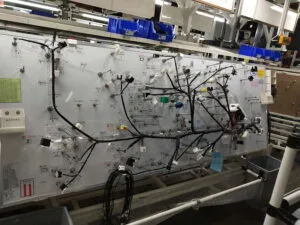

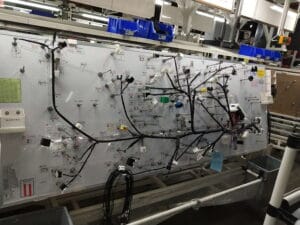

Making Custom Cable Harnesses: Technical Processes

Using advanced machinery and stringent quality control processes, we produce high-quality custom wire harnesses. Our machines use automation to make parts fast and correct. EDM machining shapes parts with great accuracy. Some steps require manual work to make sure every part is perfect. Injection molding is used to make strong harnesses. Automatic crimping locks wires tightly. Our wire harnesses go in cars, robots, medical tools, and more. We always make sure they meet the highest industry standards.

Making a wire harness prototype is the first step. This helps test if the design is suitable before making many copies. Engineers check if the wire works well in real situations. When the design is final, the wires are cut, peeled, and assembled. This makes a jumper wire harness or an industrial wire harness. Connectors and covers are added to keep wires safe.

After making the wire, tests check if everything is correct. Machines check if the wire works without problems. The last step is quality control. This ensures that every appliance’s wire harness is perfect before shipping. This whole process makes sure the wires are safe and strong.

Benefits of Using Our Custom Wire Harness

Perfect fit: Made for a specific job. No wasted space.

Safer: Prevents electric problems. Keeps everything secure.

Easy to install: Quick and simple setup.

Neat and tidy: No messy wires. Easy to manage.

Durable: Built to last for years.

Works for any industry: Fits all kinds of machines.

Strong protection: Handles heat, water, and harsh conditions.

Follows safety rules: Meets strict safety standards.

A pre-terminated wire harness makes setup fast. An industrial wire harness is strong and made for complex jobs. These harnesses help stop electric noise. This keeps signals clear and strong.

Our Work and Experiences

We have finished over 9000+ cases. We have 1200+ happy clients. With 20+ years of experience, our site is known for quality and trust. Our wire harnesses meet high safety and performance standards. Our main aim is to improve by using new ideas and precise work.

Certificates for Custom Wire Harnesses

QL-Custom Technology Ltd. makes strong, safe, and high-quality wire harnesses. The company follows strict rules to keep our products safe and reliable. There are essential certificates to prove our quality.

Our company is fully registered and meets the ISO9001:2015 quality standard. We follow UL safety rules to keep products safe. Our materials are eco friendly. They meet RoHS standards for Copper and meet RoHS standards for Plastic Resin. We also follow Reach 72-138-1 safety rules. To track all products, there is also a PPAP Document List for you.

Our harnesses pass the Water-proof IP67 test. This means they resist water. They also pass Flame Tests. They are safe from fire. Our products are strong, secure, and ready for many uses.

Best Materials Used for Custom Wire Harnesses

Choosing the right materials is very important. Copper wires are best. They carry power well. Protective covers like PVC, Teflon, and silicone keep wires safe. They stop heat, water, and chemicals from causing damage. A test version is created before making a harness. This makes sure it works well. It also helps pick the best materials for the job.

Custom harnesses help electric systems work better. They make them safer and last longer. They are used in cars, factories, and high-tech devices. They keep machines running smoothly. Businesses that use strong, custom harnesses save money and keep their machines in great shape.

A quick turn wire harness is made fast but still firm. Flexible wires, rust-free ends, and UV-resistant covers make them last longer. Suitable materials make machines safer. They also help businesses save money by avoiding repairs.

Key Components of a Wire Harness

Key Components of a Custom Wire Harness

Wires – Carry electrical current between components.

Connectors – Secure and join wires, preventing power loss.

Terminals – Attach wires to machines; may be crimped, soldered, or push-on.

Protective Sleeving – Shields wires from heat, abrasion, and contaminants.

Design Considerations for Custom Wire Harnesses

Many things matter when making a custom harness. Voltage and current decide how thick the wire should be. The wire also needs the right cover to stay safe. If the wire is too thin, it can overheat. If the cover is weak, the wire can break.

The place where the wire is used also matters a lot. Heat, water, and chemicals can hurt wires. Our custom braided wire harness lasts longer because it can handle rough places.

Wires need to be flexible. If a control panel wire harness moves a lot, it must bend without breaking. Wires in cars and planes move often, so they need to be strong and soft. Wires must also stay safe from magnetic waves and signals from other devices. Good planning makes sure the wire works well for a long time.

Common Issues: Solved by Our Customization

Poor Fit – Normal wires may not fit well. A custom turnkey wire harness is made to fit perfectly.

Weak Connections – Loose wires can cause problems. A pre-terminated wire harness has strong and ready-to-use ends.

Wire Damage – Bending too much can break wires. A pigtail wire harness helps stop breaks.

Environmental Wear – Heat, cold, and water can damage wires. A custom braided wire harness lasts longer in challenging places.

Complex Assembly – Some wires take too long to install. A quick turn wire harness is easy to use and saves time.

Future of Electrical Harnesses

Wire harnesses will get better in the future. Machines will help make wire harness prototypes faster. New materials will make overmolded wire harnesses stronger and lighter.

Innovative design tools will make control panel wire harnesses work better. More cars and homes will use electric power, so high-voltage cables will be needed. Some wires might even have tiny chips to check their health. The future looks exciting for wire harnesses.

Real-World Applications: Engine Harness

Planes and cars need custom wiring harnesses to work well. Planes need wires that handle heat, shaking, and electric signals. Overmolded wire harnesses help keep planes safe. They help power and control many systems inside the plane.

Cars need jumper wire harnesses to connect many parts. Lights, screens, and safety tools all use wires. More electric cars mean more wire harnesses that handle considerable power. Strong and safe wires make cars better and safer.

Best Custom Wire Harnesses QL-Custom Offer

ECU Tuning Wire Harness

This harness helps the engine talk to sensors. It makes the engine work better and saves fuel. It is made with strong materials so it lasts long. We test every harness to make sure it works well. If you want your car to run better, this harness is for you.

Oil Gas Sensor Wire Harness

This harness works in the oil and gas industries. It helps sensors read data correctly. It can handle heat, cold, and chemicals. Our strong insulation keeps wires safe. This harness helps keep machines running safely and smoothly. Using our product means fewer problems and lower costs.

ISO Wire Harness

This harness meets global safety rules. It is excellent for cars, machines, and other industries. It keeps wires connected and stable. Our ISO harnesses are built to last. They fit into any system easily. Businesses trust this harness because it is reliable.

Truck Engine Wire Harness

Trucks need strong wire harnesses to work right. Our truck engine harness keeps everything connected. It is made to handle heat, cold, and shaking. Even in rough conditions, it keeps the truck running well.

Forklift Engine Harness

Forklifts need good wiring to lift heavy things safely. Our forklift harness is rigid. It does not break easily and keeps working all day. No matter where forklifts are used, our harness helps them run better.

Who Uses Our Wire Harnesses?

Automotive: Cars and trucks need Custom wire harnesses to work well. Our harnesses help different car parts talk to each other. This makes driving safer and smoother. QL-Custom works with car makers to build the best harnesses for vehicles.

Aerospace: Airplanes and space machines need safe wiring. Our harnesses work well under extreme heat, cold, and pressure. They help planes fly safely. Our team makes sure every harness meets the highest safety standards.

Electronics: Wires in gadgets must be appropriately connected. Our harnesses help electronic devices work correctly. They are strong and last a long time. There are harnesses for phones, computers, and medical devices.

Manufacturing: Factories need wiring to keep machines running. Our wire harnesses connect machines safely. This helps factories work faster and better. Our harnesses lower the chances of machine failures.

QL-Custom Technology Ltd.

At QL-Custom Technology Ltd., we specialize in high-quality wire harnesses designed to improve machine efficiency and safety. Whether you need harnesses for cars, planes, or industrial machinery, we deliver customized solutions tailored to your needs. Our expert team and top facilities help us deliver the best harnesses. If you need a strong and safe wire harness, trust us to provide it.

People Also Ask

What is a custom wire harness?

A custom wire harness is a bundle of wires put together to connect different parts of a machine. It keeps wires neat and safe and helps machines run without trouble. Without it, wires can get messy and break, causing problems.

Is a wire harness better than loose wires?

A wire harness keeps wires from getting tangled, bent, or broken. It holds them in place so machines work better and don’t fail. It also makes repairs easier and cuts down on fixing time and costs. Loose wires can rub together, wear out, and stop working over time.

Where can I use wire harnesses?

Wire harnesses are used in cars, planes, factories, and homes. They help electrical parts work safely and competently. You can also find them in medical tools, smart home devices, and everyday electronics.

Can I choose QL-Custom Technology Ltd. for wire harnesses?

Yes. At QL-Custom Technology Ltd., make high-quality, long-lasting wire harnesses that are safe and fit perfectly. Our products are designed to work well and stand the test of time. Whether you need harnesses for cars, machines, or special equipment, there are top solutions for the best performance.

How do wire harnesses make machines safer?

They keep wires in place so they don’t move, overheat, or wear out too fast. This lowers the risk of short circuits, fires, and machine breakdowns. They also protect wires from water, dust, and damage, keeping machines running longer.

What makes a custom wire harness special?

A custom harness is made for a specific machine. It is the right size, shape, and type for the job. This makes it last longer and work better than regular wires that might not fit as well.

Can a custom wire harness save money?

Yes! A strong wire harness stops wires from breaking, so there are fewer repairs and less downtime. Since it lasts longer, you don’t have to replace it as often. Businesses save money and keep machines working smoothly.

What materials are used in wire harnesses?

Wire harnesses are made from strong materials to make them last. The wires are usually copper because they carry electricity well. The cables are covered with coatings like PVC, Teflon, or silicone to protect them from heat, water, and dirt.

Can I use custom wire harnesses in electric cars?

Yes! Electric and hybrid vehicles need special wire harnesses to handle power safely. These harnesses help send electricity while also making the car lighter. As more people use electric vehicles, high-quality wire harnesses are more crucial than ever.

Are the wire harnesses tested?

Before they are used, wire harnesses undergo strict tests to ensure they work well and are safe. Tests check if electricity flows correctly if the wires are strong, and if they can handle real-world conditions without failing.

FAQs

Why do I need this tool?

If regular cables don’t fit, a custom harness is the answer. It makes things work better.

Where are these items used?

These are used in vehicles & mechanical tools. They help machines run smoothly.

What is the manufacturing process of it?

Experts design, cut, and arrange the wires. Then, they add connectors and test everything.

What is the price of it?

It depends on the materials and design you pick.

What is the estimated time amount it could take?

It depends on the design. Simple ones take days. Complex ones take weeks.

Delivery Time & Order for Custom Wiring Harness

QL-Custom is a B2B manufacturer. We know fast delivery is essential. QL-Custom has flexible minimum order quantities (MOQ). The team handles small orders and large orders. Our production is fast. You can get your orders in a short time. Our team replies to questions within 4 hours. Our team is ready to help with custom requests.

Wire Harness Design & Diagram