Que plásticos podem ser utilizados para isolamento de fios e revestimento de cabos?

Por Tina / 2024年10月24日

Que plásticos podem ser utilizados para isolamento de fios e revestimento de cabos?

O isolamento de fios e o revestimento de cabos são essenciais em aplicações eléctricas, o que significa que os materiais utilizados são cruciais para garantir a segurança, o desempenho e a durabilidade dos cabos. Então, que plásticos podem ser utilizados como materiais de isolamento e revestimento de fios e cabos?

Compreender o isolamento dos fios e o revestimento dos cabos

Definição de isolamento de fios

Para utilizar corretamente o isolamento do fio, é necessário saber o que é. O isolamento de um fio é uma camada de material não condutor que envolve um condutor. Impede eficazmente as fugas e protege o condutor de factores ambientais externos, evitando acidentes como fugas, curto-circuitos e choques eléctricos provocados pelo contacto entre o condutor interno e o exterior.

Definição de revestimento de cabos

O revestimento de cabos é uma camada protetora que envolve vários fios ou cabos isolados. São utilizadas para proteger os fios internos de danos ambientais externos, tais como danos físicos, humidade, produtos químicos e radiação UV. O isolamento de fios visa principalmente fios individuais, enquanto o revestimento de cabos pode proteger vários fios ou cabos

Que materiais são utilizados para o isolamento de fios?

Cloreto de polivinilo (PVC)

O PVC tem excelentes propriedades eléctricas, boa flexibilidade e pode ser utilizado em ambientes húmidos, o que o torna um dos materiais mais utilizados para o isolamento de fios. O preço do PVC é muito vantajoso, o que constitui também uma razão importante para a sua utilização generalizada.

Polietileno reticulado (XLPE)

O XLPE em si não é um plástico, mas o composto de borracha PE é irradiado após a extrusão para reticular as suas moléculas químicas, tornando-o mais resistente à temperatura após o envelhecimento.

O XLPE tem uma resistência ao calor extremamente elevada. Pode suportar temperaturas mais elevadas. Os cabos isolados com XLPE podem trabalhar num ambiente de 90°C durante muito tempo. Mais notoriamente, pode suportar temperaturas instantâneas de curto-circuito de 170-250°C.

Polietileno (PE)

O polietileno divide-se principalmente em três categorias: polietileno linear de baixa densidade (LLDPE), polietileno de baixa densidade (LDPE) e polietileno de alta densidade (HDPE). O PEAD tem uma força e resistência ao impacto muito boas, enquanto o PEBD é mais proeminente em termos de flexibilidade e facilidade de processamento. Ambos são frequentemente utilizados para o isolamento de fios.

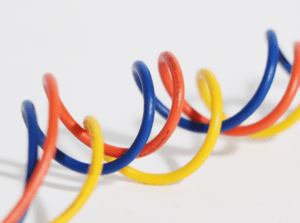

Elastómero termoplástico (TPE)

O elastómero termoplástico, também conhecido como borracha artificial ou borracha sintética, pode ser processado por moldagem por injeção como o plástico, embora seja tão macio como a borracha. Combinando as vantagens da borracha e do plástico, tem uma excelente flexibilidade e durabilidade.

Borracha de silicone

A borracha de silicone tem um excelente desempenho e pode ser utilizada em ambientes extremamente frios ou quentes. Proporciona um excelente isolamento como material de isolamento de cabos. É normalmente utilizada em ambientes aeroespaciais e de alta tensão exigentes.

Teflon (PTFE)

O Teflon pode ser utilizado continuamente num ambiente a 260°C, com uma temperatura máxima de funcionamento de 290-300°C. Até à data, quase nenhuma substância sólida consegue aderir permanentemente ao Teflon. É anti-aderente, resistente a altas temperaturas e tem uma boa estabilidade química.

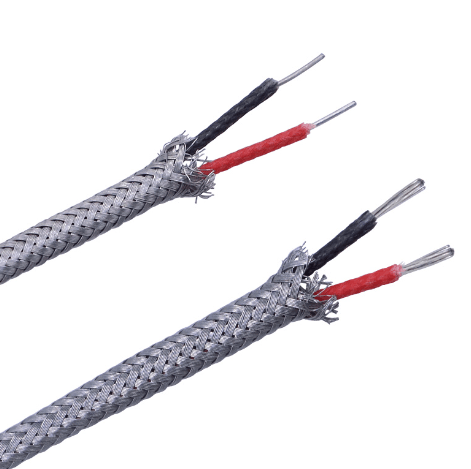

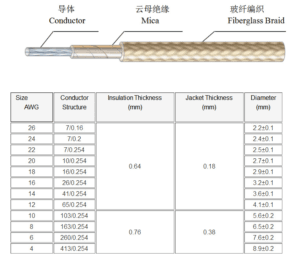

Fibra de vidro

A fibra de vidro tem muitas vantagens, tais como forte resistência ao calor, bom isolamento e resistência à corrosão, e elevada resistência mecânica. É normalmente utilizada em aplicações de alta temperatura.

Que materiais são utilizados para revestir os cabos.

Cloreto de polivinilo (PVC)

O PVC pode ser utilizado não só para o isolamento de fios, mas também para o revestimento de cabos.

Baixa emissão de fumos e sem halogéneos (LSZH)

Em caso de incêndio, a queima de um grande número de cabos num espaço confinado produzirá uma grande quantidade de fumaça preta, aumentando a dificuldade de fuga. Os cabos de baixa emissão de fumaça e sem halogéneos (LSZH) libertam uma quantidade mínima de fumaça e não libertam halogéneos quando expostos ao fogo, tornando-os cabos mais seguros em caso de incêndio e adequados para utilização em espaços confinados, como transportes públicos e edifícios.

As formas abreviadas incluem LSZH, LSOH, LS0H, LSFH e OHLH

Poliuretano (PU)

O poliuretano tem a flexibilidade da borracha e é mais resistente ao desgaste, o que o torna adequado para ambientes propensos ao desgaste mecânico.

Borracha

Os materiais de borracha são muito flexíveis e são frequentemente utilizados no revestimento de cabos. São frequentemente utilizados em aplicações no exterior.

![]()

Elastómero termoplástico (TPE)

O TPE pode ser utilizado tanto para o isolamento de fios como para o revestimento de cabos, oferecendo um serviço abrangente de flexibilidade e durabilidade para muitas aplicações.

Em resumo, a segurança e a qualidade do desempenho das aplicações eléctricas dependem em grande medida dos materiais plásticos utilizados no isolamento dos fios e no revestimento dos cabos. A compreensão das caraterísticas dos diferentes materiais permite-nos fazer rapidamente as escolhas certas com base nas nossas necessidades específicas.