our recommendation of

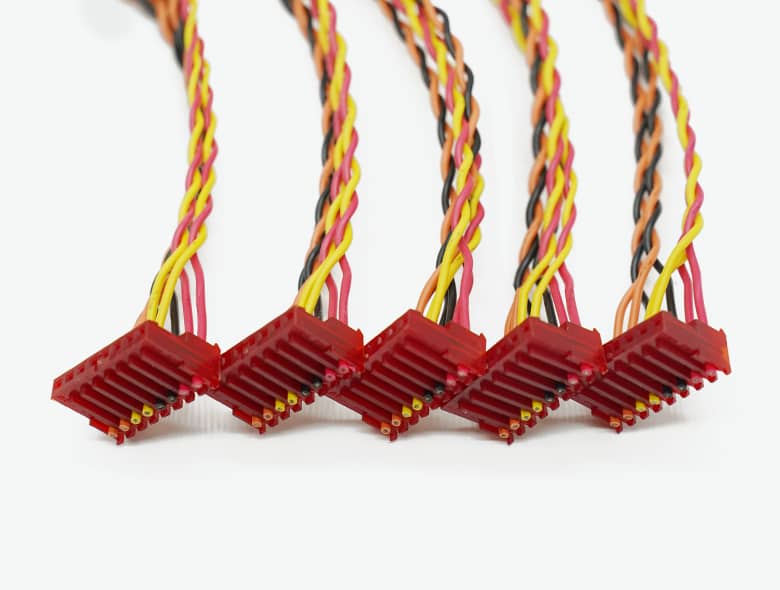

Custom Wire Harness Materials

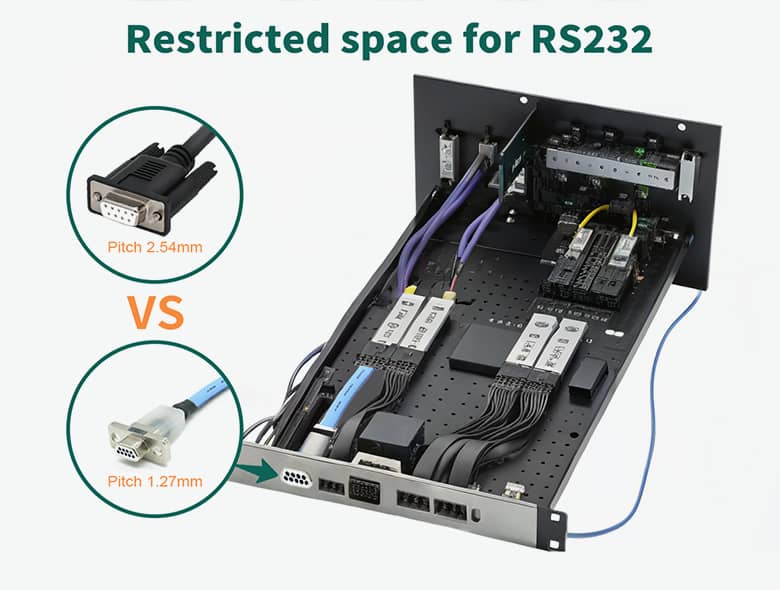

Normally, many customers already have wire harness designs, but some customers initially only have an idea. This is when they need us the most, because they are unclear about the selection of connectors and cables. These types of customers don’t have specific requirements for the appearance of the connectors. This is when QL-Custom truly takes control of custom wire harness applications and adds value. We are happy to help customers solve these types of problems.

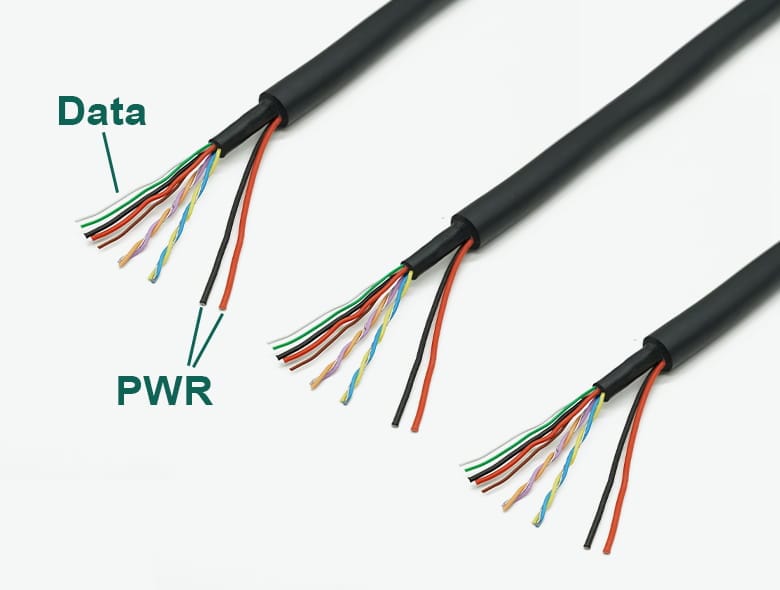

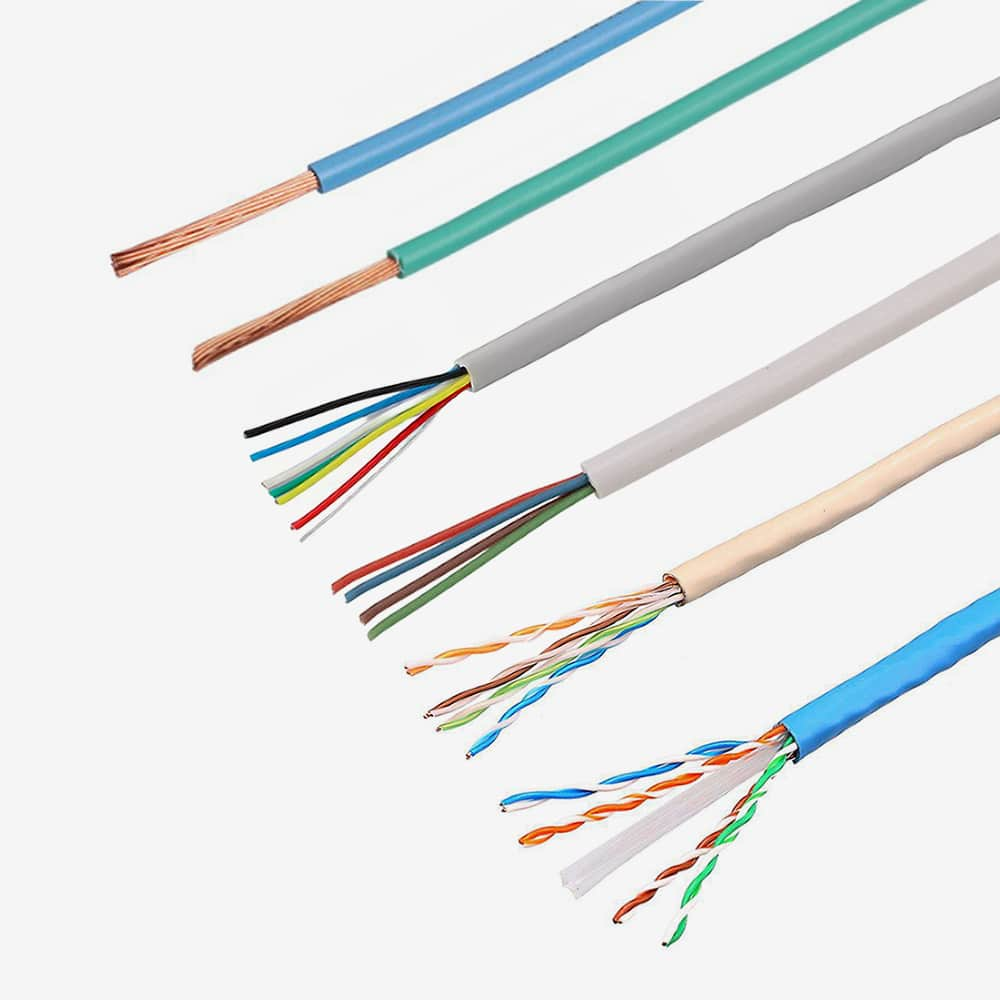

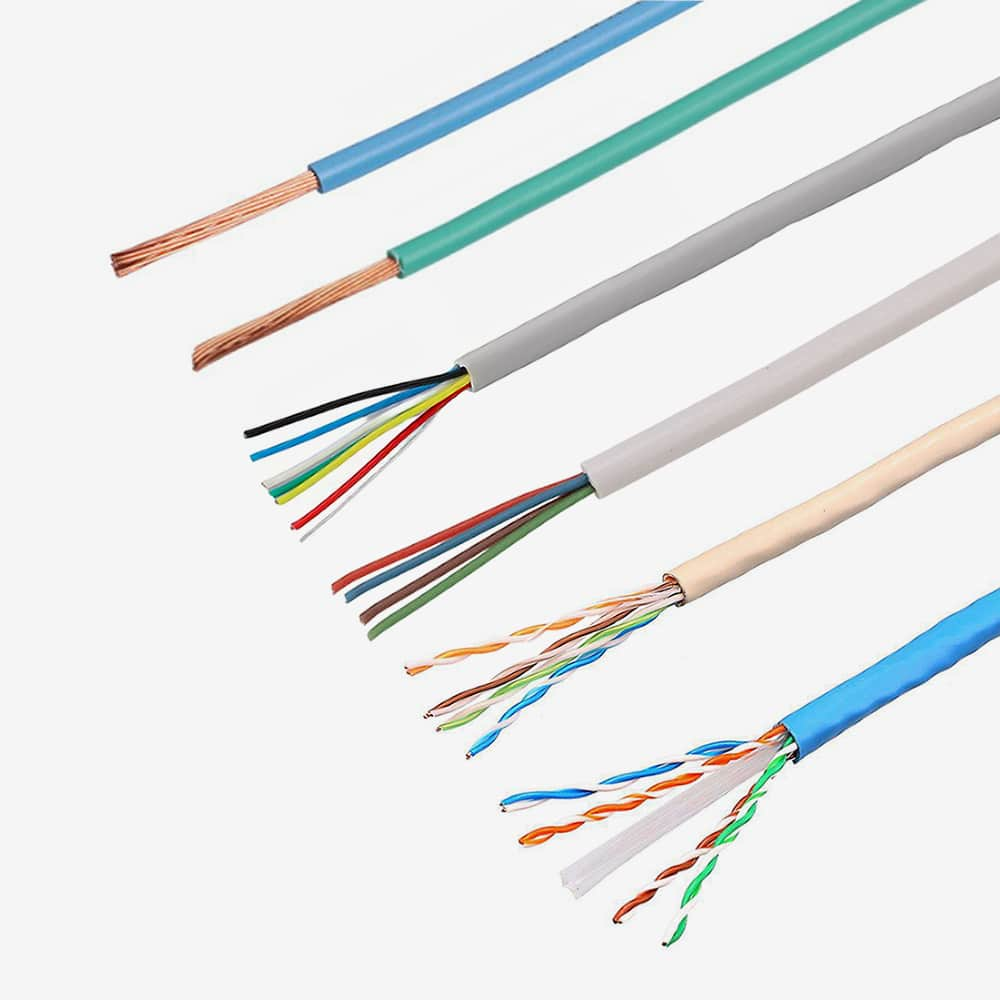

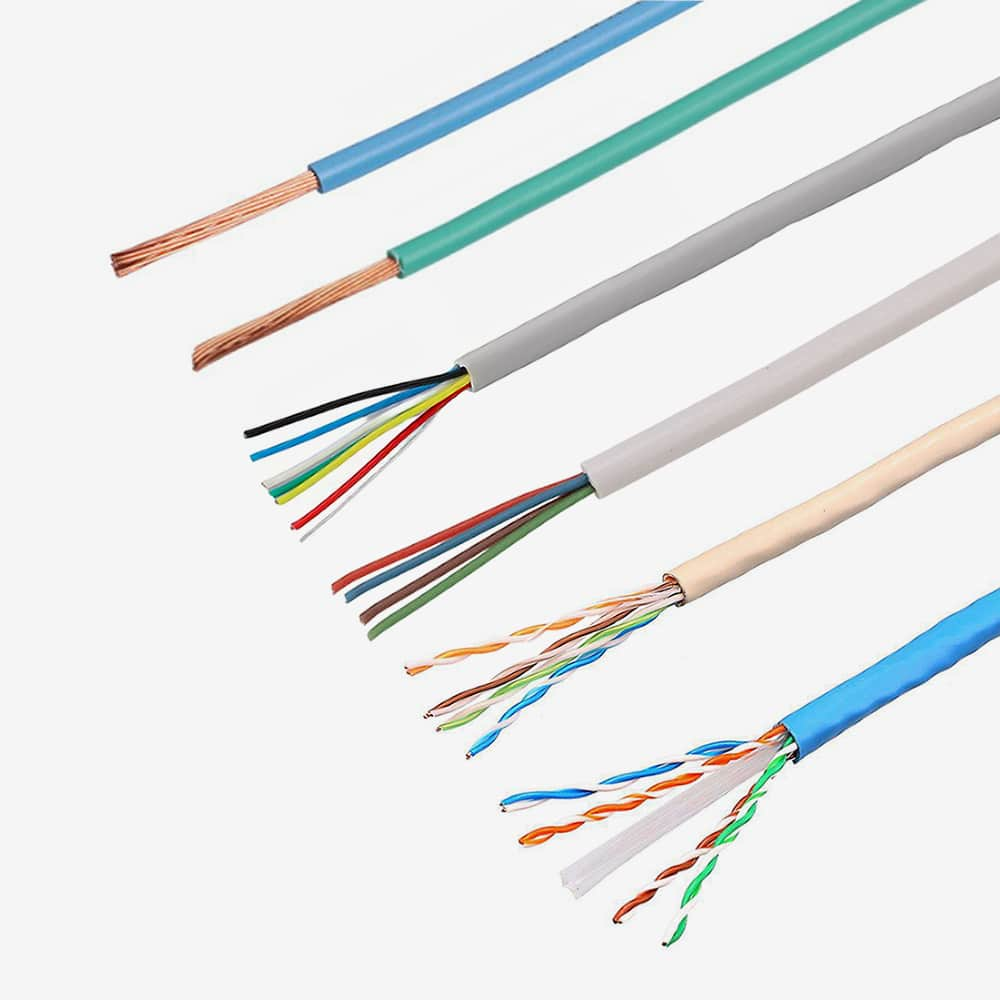

Hook up wires and CAN signal wires options

Special Purpose Wire and Cables

Cable Fire Proof

UV Resistant Cable and Wires

Equal Wire and Connectors

Popular Brand Wire and Connectors

Rectangle or Circular Connectors

Hook up wires and CAN signal wires options

Special Purpose Wire and Cables

Equal Wire and Connectors

Rectangle or Circular Connectors

Popular Brand Wire and Connectors

Cable Fire Proof

UV Resistant Cable and Wires

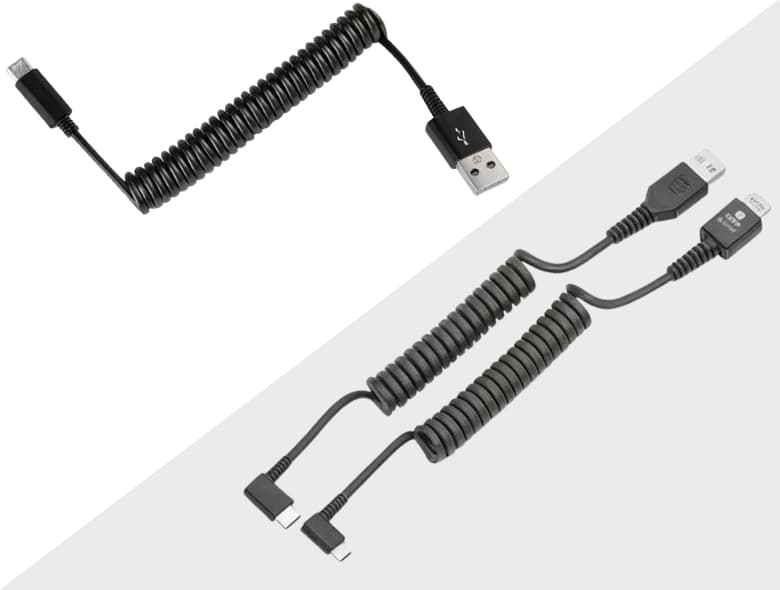

Custom Wire Harness Solution Service

Simply put, custom wire harness solutions meet all your wiring harness needs. Some suppliers don’t provide certain services, leaving customers to provide those. If everything is provided by the customer, what do we do? If we can't meet the customer's wire needs, what value do we add? How long can a supplier that doesn’t consider custom requirements survive? Therefore, you can rest assured when handing over your requirements to us. Your project is our project.

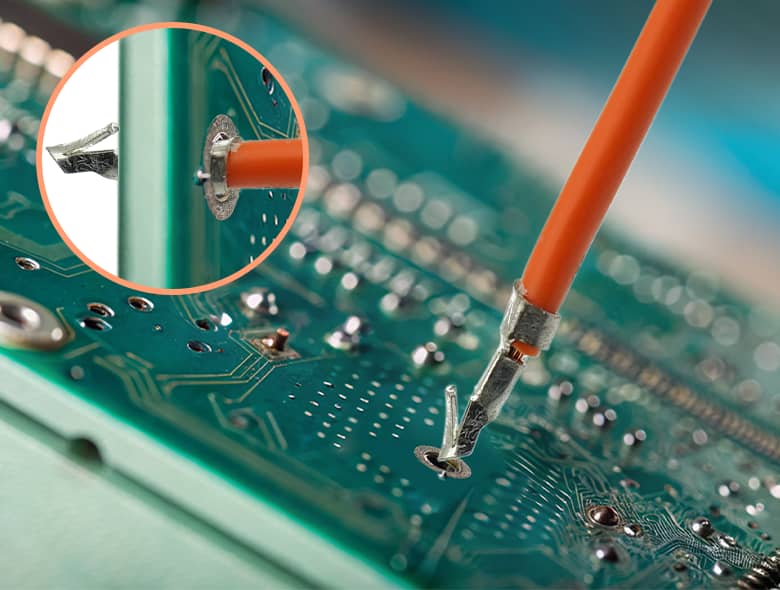

Custom Overmolded Cable Assemblies

When obtaining overmolded cable assembly quotes, have you often received mold quotes costing hundreds or even thousands of dollars? This is because the product hasn’t been made before. At QL-Custom, we have thousands of molds, which allows us to save costs wherever possible. Of course, if your requirements are special, we can also provide quotes in the shortest time.

Custom Tooling Service

From simple to complex molds, from PVC, TPE to high-temperature plastics, you can contact us to get the best and fastest quotes and solutions. We assist you in completing your project evaluation and implementation.

Special Purpose Plastic Overmolded Cables

When you have special requirements using TPE, TPU, or Nylon molding, you will notice that their molding temperatures and adhesion between the molded body and material are different. QL-Custom has fully mastered these molding techniques, including the temperature of the molding machines and the injection pressure adjustments.

Overmolded Hood Durability

When designing plug fixed positions, some customers may opt for panel mount requirements. Panel mounting needs to ensure whether the screws are external or internal locking, and determine the screw hole spacing and connector exposed length to avoid narrow terminal contact surfaces, which could increase current or signal impedance.

Panel Mounted Overmolded Cable Plugs

When designing plug fixed positions, some customers may opt for panel mount requirements. Panel mounting needs to ensure whether the screws are external or internal locking, and determine the screw hole spacing and connector exposed length to avoid narrow terminal contact surfaces, which could increase current or signal impedance.

Overall Cable Part Overmolding Solutions

Full encapsulation of the wires means that all wires between connectors are fully overmolded. Based on molding principles, the longest molding length can be 130-140mm, and anything longer could result in poor molding. This solution is suitable for short-distance FPC flat wires, as well as medical or adult product designs.

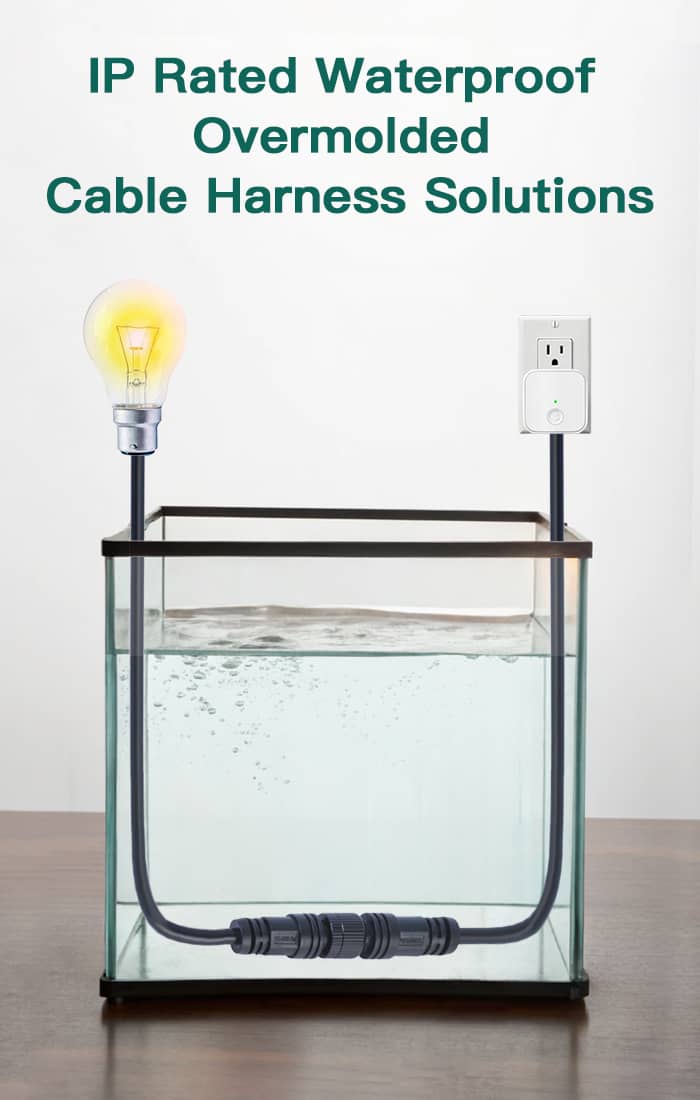

IP Rated Waterproof Overmolded Cable Harness Solutions

Custom cable harnesses with waterproof ratings require a concept of waterproofing in the overall product design. IP67, IP68, or even IP69 designs must use male and female connectors together, not just male connectors or female connectors. Or connectors to boards. The design must ensure a waterproof seal between solid hardware components when the male and female connectors are inserted or when connectors are mounted on boards. If just two pieces of hardware connect directly, complete waterproofing cannot be achieved.

Trust us one time , you will get more confidence to gain your expected product !

We are alway here to help your wire harness business

Custom Wire Harness Quotation and MFG Service

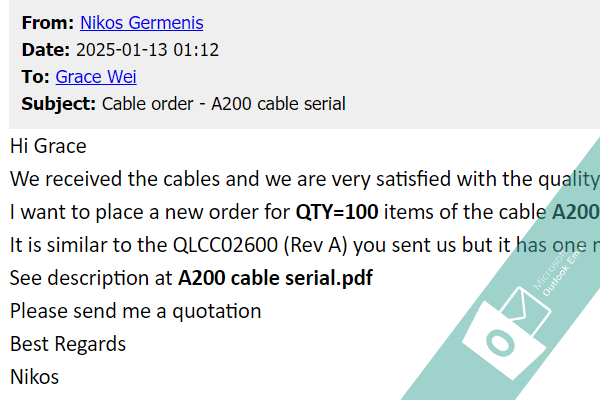

Are you still struggling to find the right custom wire harness supplier? Contact us to solve the difficulties you face and get a great quote. Contacting us will help you solve a series of challenges and ensure that your project will no longer struggle with custom wire harnesses. A quick and easy solution.

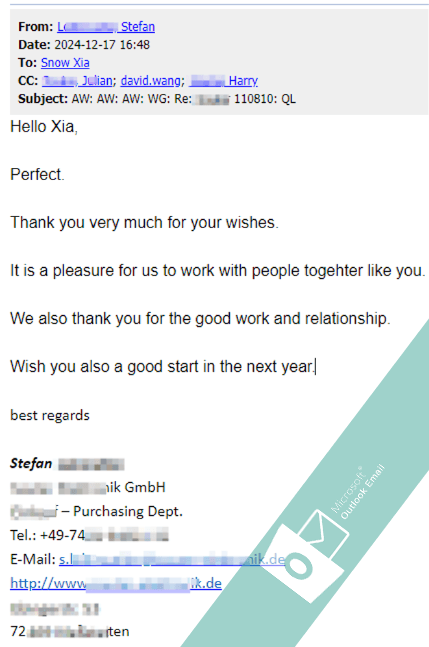

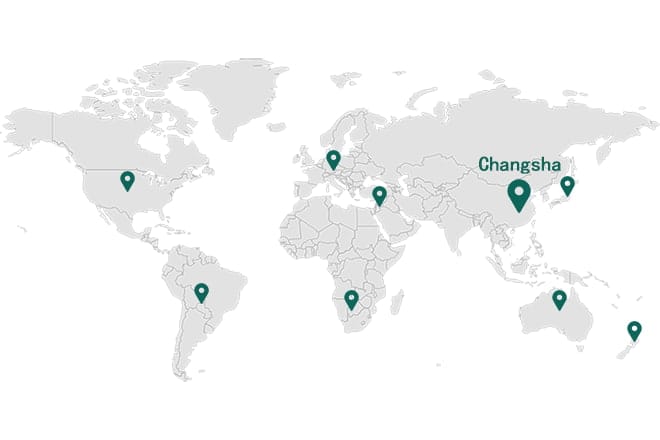

North America or Europe Customers

Do you think your local suppliers produce everything locally? If so, why do we have over a thousand customers in our industry? Contact us and you'll realize how affordable QL-Custom custom wire harnesses are, how reasonable our solutions are, and how fast our samples can be.

1

Get a Very Quick Response Quote

From simple to complex wire harnesses, we only need 30 minutes to 4 hours to respond.

2

Quick Turn Samples

As long as the raw materials don't require customization, your sample can be shipped on the same day from the drawing to the first sample.

3

Mass Production

To ensure product quality, we usually complete production within 2-3 weeks based on quantity, but for larger quantities, we can discuss and determine the timeline together.

4

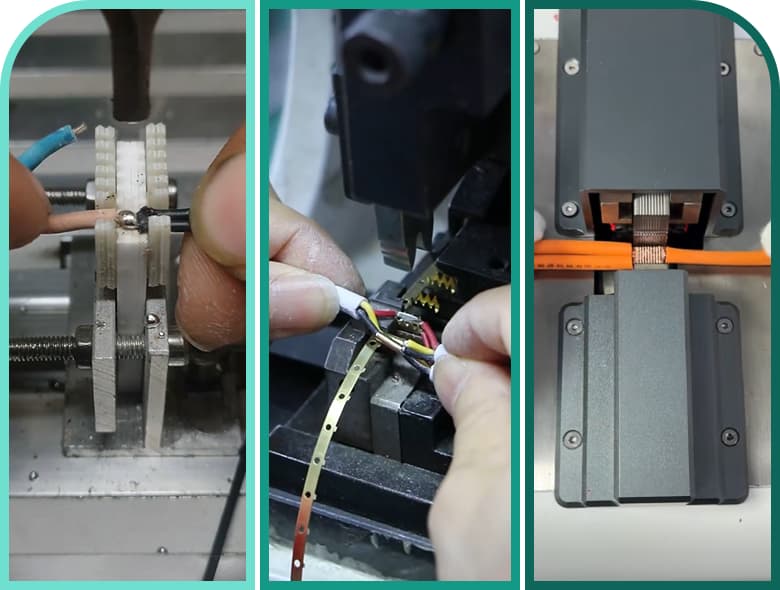

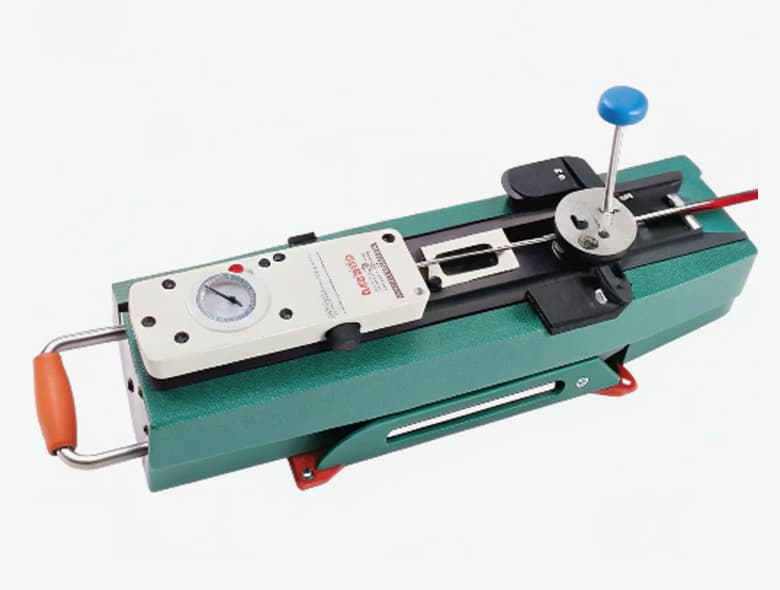

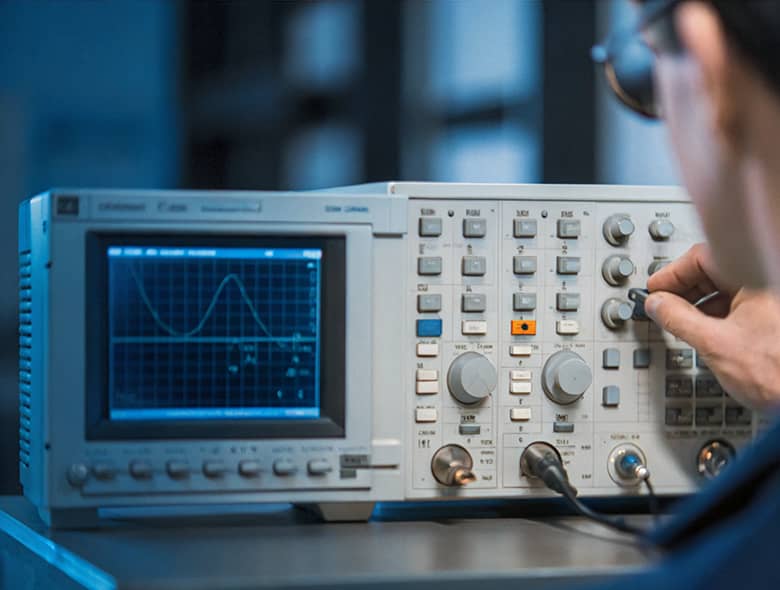

Guaranteed Quality

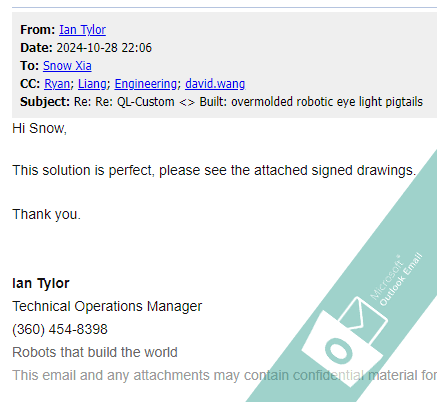

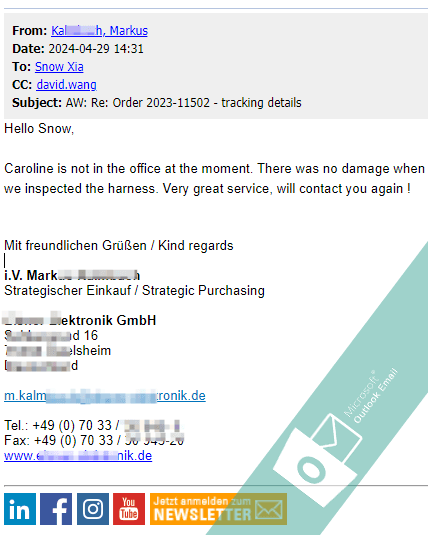

Every wire harness shipped from QL-Custom goes through 100% quality inspection, including both appearance and electrical performance. We always include a test report in the box with each shipment. Please check carefully upon receipt. If there is any quality feedback, we will immediately initiate an investigation. Therefore, when we ask you to sign the drawings, please make sure to confirm everything before signing and sending them to us.

5

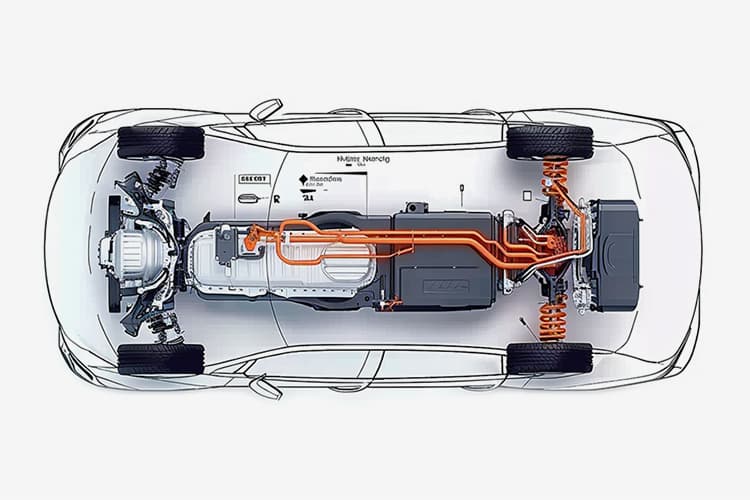

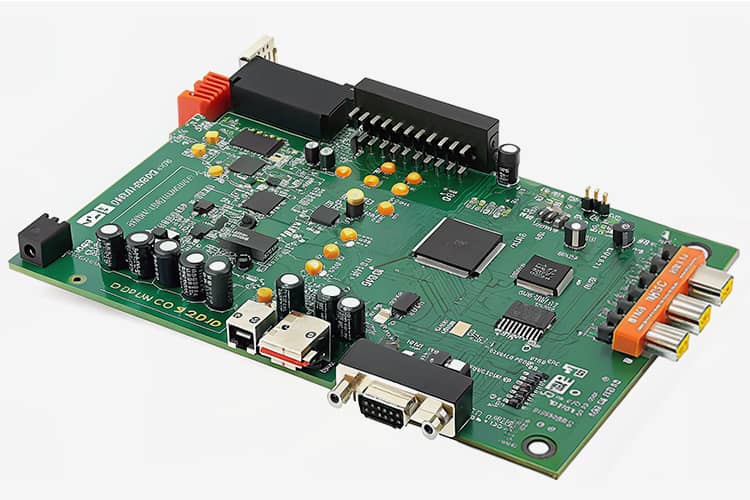

Custom Wire Harness Applications

Wire harness applications are very broad. If you want to know which industries wire harnesses serve, you can refer to the list we have provided, but of course, we serve beyond that. If you have additional questions or need to learn more, we are more than happy to assist. If you have cooperation needs, feel free to contact us. We will respond as quickly as possible.

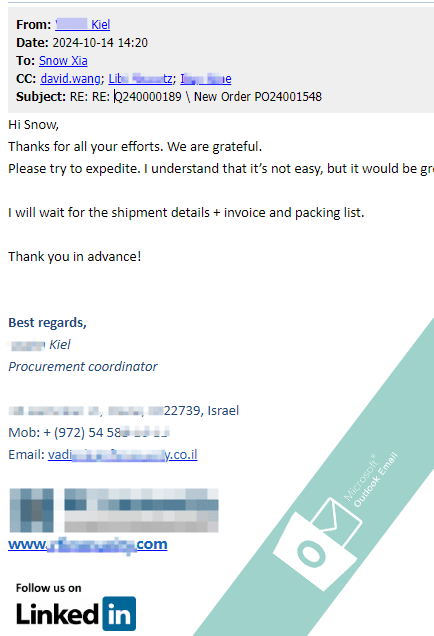

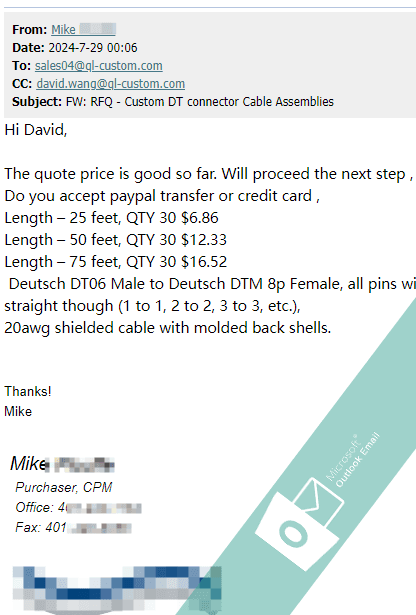

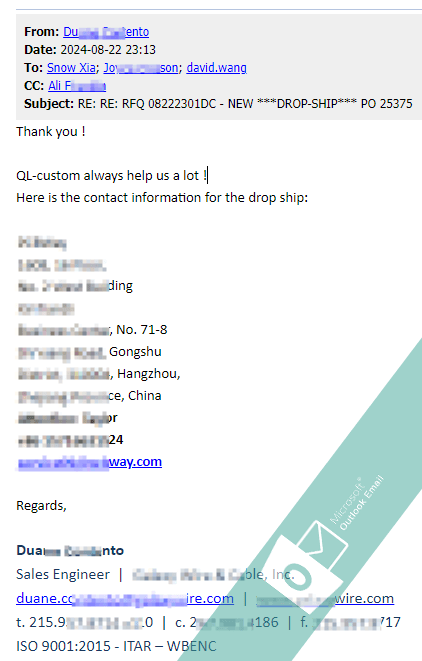

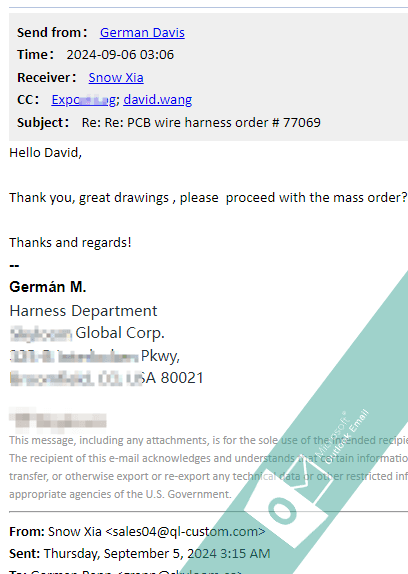

Email Customer Feedback