Was ist Spritzgießen?

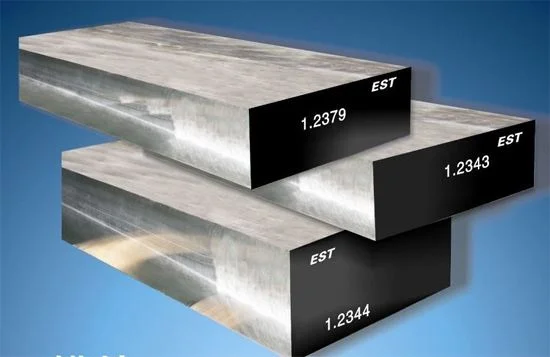

Spritzgießen ist ein Herstellungsverfahren, das von Steel Formwerkzeug wird die Kunststoffschmelze in den Behälter gegossen. Formhohlräume nach sofortige Kühlung und die gleiche Form der Teile ausgeben. Das Spritzgießen wird meist verwendet, wenn eine große Anzahl von identische Produkte in einer kurzen Vorlaufzeit (derzeit 3 Wochen). Der Prozess kann mit verschiedenen Methoden durchgeführt werdenKunststoffmaterialien einschließlich Polymere, Elastomere und duroplastische Harze.

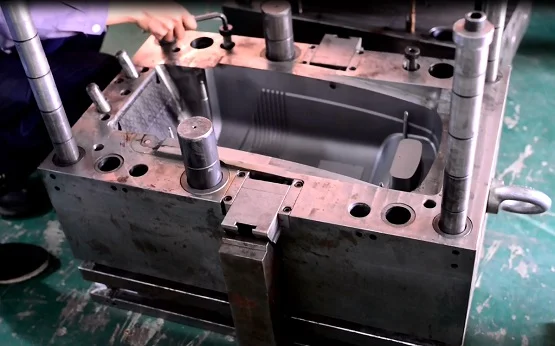

Spritzgießen einschließlich Horizontales Kunststoffspritzgießen und Vertikales SpritzgießenDas Werkzeug für das Kunststoffspritzgießen ist viel größer als das vertikale Spritzgießwerkzeug. Derzeit Kunststoffteil Gießen durch eine große Form wie Licht Abdeckung, Container, Flaschenverschlüsse, Haushaltsgeräte, Kunststoffteile, elektronische Box, Bildschirmrahmen, Spielzeug und so weiter. Vertikale Spritzgießen oft in Verkapselung auf verwendet werden Kabelkonfektionen und Komponenten.