Kundenspezifischer Kabelbaum

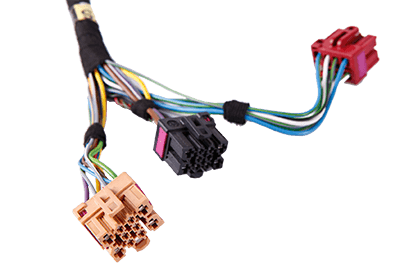

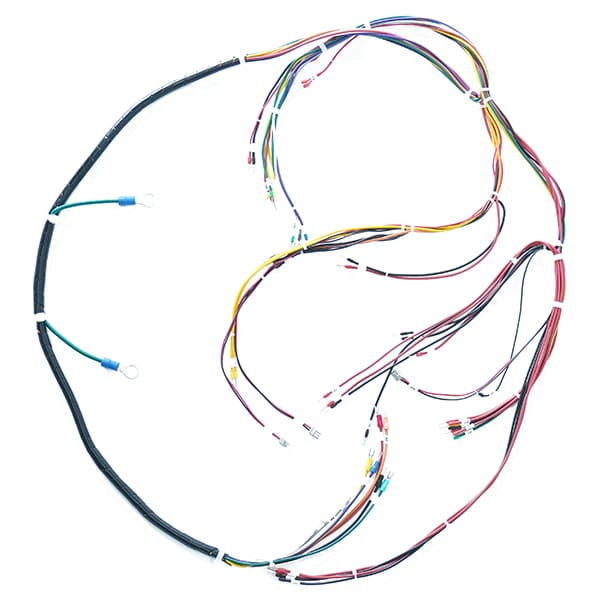

Kundenspezifische Kabelbäume, was ist das, Arten, Unterschiede, Anwendungen Besseres Verständnis von QL-Custom: Kabelbäume, Kabelbaugruppen und Kabelbäume In QL-Custom haben wir monatliche Schulungen zu Kabelbaumbaugruppen Wissen. Einige unserer Kunden, sogar unsere Konkurrenten, verstehen nicht, was der wirkliche Unterschied zwischen kundenspezifischen Kabelbäumen, Kabelkonfektionen und Kabelbäumen ist. Heute geben wir Ihnen ganz einfache Erklärungen. Bevor wir darüber sprechen, sollten wir klarstellen, was ein Draht und was ein Kabel ist. Anschlussdrähte sind Einzeldrähte mit Isolierung, einfarbig oder zweifarbig; sie haben keinen Bezug zum Leiter; Kabel sind mehrere Einzeldrähte in einem Bündel mit einer Kunststoffummantelung. Mit Abschirmung oder ohne Abschirmung. Ok, jetzt ist Ihnen klar, was ein Draht ist und was ein Kabel, und Sie können sich denken, worüber ich als Nächstes sprechen möchte! Ein Kabelbaum ist ein Kabelbaum, der mehrere Kabel, einschließlich verschiedener Drähte, Stecker und Klemmen in einem Satz zusammenfasst. Damit ist die Kabelkonfektionierung klar Eine Kabelkonfektionierung, die nur mindestens ein mehradriges oder mehr als einteiliges Kabel, Steckverbinder, Klemmen oder Lötdrähte umfasst, Damit ist die Kabelkonfektionierung auch klar Kabelkonfektionierung, die nur mindestens ein mehradriges oder mehr als einteiliges Kabel, Steckverbinder, Klemmen oder Lötdrähte umfasst und diese zu einem Satz umspritzt. umspritzt. zu einem Satz umspritzt. Und der Kabelbaum - verstehen Sie das jetzt? Sie können David anrufen, um mehr zu besprechen. +86 13790139296 Kundenspezifische Kabel- und Kabelbaumbaugruppen Anwendung Computer Ein Computer-Kabelbaum, auch bekannt als Kabelbaum, Kabelbaugruppe, Verdrahtungsbaugruppe oder Kabelbaum, ist eine systematische und organisierte Anordnung von Drähten, Kabeln und anderen Komponenten, die elektrische Energie übertragen...

Mehr lesen "Kabelbaum Hersteller

Der Kabelbaumhersteller QL-Custom Technology Limited steht an der Spitze der Kabelbaumherstellung und ist auf die Produktion einer breiten Palette von Produkten spezialisiert, darunter Kabelbaumbaugruppen, Kabelbäume, Kabelbaumlösungen und kundenspezifische Kabelbäume. Unsere Kompetenz erstreckt sich auf die sorgfältige Herstellung hochwertiger Kabelbäume mit Schutzumhüllungen aus duroplastischen oder thermoplastischen Materialien. Diese Schutzummantelungen spielen eine entscheidende Rolle beim Schutz elektrischer Leitungen vor Umweltgefahren und potenziellem Verschleiß. Wir sind stolz darauf, kundenspezifische Kabelbäume für verschiedene Anwendungen in Branchen wie Elektronik, Medizin, Automobil, Telekommunikation, Militär, saubere Energie und andere hochpräzise Sektoren zu liefern, die sich durch eine unerschütterliche Verpflichtung zu strengen Qualitätsstandards auszeichnen. Als angesehener globaler Auftragsfertiger erfüllen unsere innovativen Lösungen die einzigartigen Bedürfnisse von Erstausrüstern (OEMs) und Unternehmen in verschiedenen Sektoren. Bei QL-Custom Technology Limited haben wir uns auf umspritzte Kabelbaugruppen und Kabelbäume spezialisiert, die ein Höchstmaß an Schutz für die Drähte gewährleisten. Unser umfassendes Angebot umfasst Kabelbäume, Batteriekabel und kundenspezifische Kabelkonfektionen, die auf die spezifischen Anforderungen unserer Kunden zugeschnitten sind. Gestützt auf engagierte und erfahrene Mitarbeiter auf der ganzen Welt sind wir stolz auf unsere führende Position in der Branche und bieten Mehrwertdienste wie Kunststoffspritzguss, Niederdruckspritzguss (PCB-Überspritzung) und Box-Build-Lösungen. Unser umfassendes Fachwissen erstreckt sich über verschiedene Bereiche, einschließlich, aber nicht beschränkt auf Datenübertragung, Crimpkontakte, optische Fasern und Lichtwellenleiter. Ob es darum geht, die Anforderungen modernster automatisierter Antriebstechnologien zu erfüllen, die Installation von Solaranlagen zu erleichtern oder Lösungen für die Unterhaltungselektronik anzubieten, QL-Custom Technology Limited ist Ihr zuverlässiger Partner. Wir sind bestrebt, erstklassige Kabelbaum- und Kabelkonfektionslösungen zu liefern, die den sich entwickelnden Anforderungen der Industrie gerecht werden. Wählen Sie QL-Custom Technology Limited für Spitzentechnologie, zuverlässige Produkte,...

Mehr lesen "Was ist Thermoelementdraht? Typen und Verwendungen, ein Überblick

Was ist Thermoelementdraht? Thermoelementdraht oder -kabel wird in einem Thermoelement verwendet, das die Temperatur über die Vergleichsstelle misst. Thermoelementdraht wird zur Steuerung von Messgeräten und zum Aufbau der Messstelle in einem Thermoelement verwendet und besteht aus zwei unterschiedlichen Metallen. Umspritztes Thermoelementkabel Nutzbare Längen von Thermoelementdraht Es gibt viele Faktoren, die sich auf die nutzbare Länge eines Thermoelements auswirken. Die beiden Hauptfaktoren, die die nutzbare Länge eines Thermoelementdrahtes beeinflussen, sind der Gesamtwiderstand der Schleife und das elektrische Rauschen. Thermoelementdrähte werden aus verschiedenen Leitermaterialien hergestellt. Aus diesem Grund variiert der Gesamtwiderstand der Schleife je nach Typ, Drahtdurchmesser und Länge. Das Hauptziel für eine brauchbare Länge eines Thermoelementdrahtes ist jedoch, den Schleifenwiderstand unter 100 Ohm zu halten. Je länger der Draht ist, desto größer ist die Wahrscheinlichkeit, dass er durch elektrisches/gestrahltes Rauschen beeinflusst wird. Diese große Länge des Drahtes wird dann die Leistung des Drahtes beeinträchtigen. Daher wird empfohlen, die nutzbare Länge des Thermoelementdrahtes nicht zu verlängern oder ein Minimum von 10 Fuß zu überschreiten. Wird der Draht verlängert, empfiehlt es sich, eine Abschirmung zu verwenden, um die Rauschstörungen auf ein akzeptables Niveau zu reduzieren. Zu diesem Zweck kann ein Metalldraht oder ein verdrillter abgeschirmter Draht verwendet werden. Gleichzeitig sollte die Verlegung von Kabeln in der Nähe von empfindlichen Bereichen wie Motoren und Stromkabeln vermieden werden. Alles in allem ist das empfohlene Ziel für eine brauchbare Kabellänge, das Kabel auf weniger als 100 Fuß mit 20 AWG oder dickerem Kabel in einem Bereich frei von elektromagnetischen Störungen zu halten. Nachdem wir nun die empfohlenen Längen definiert haben, wollen wir uns mit den verfügbaren Thermoelementdrähten und ihren Unterschieden beschäftigen....

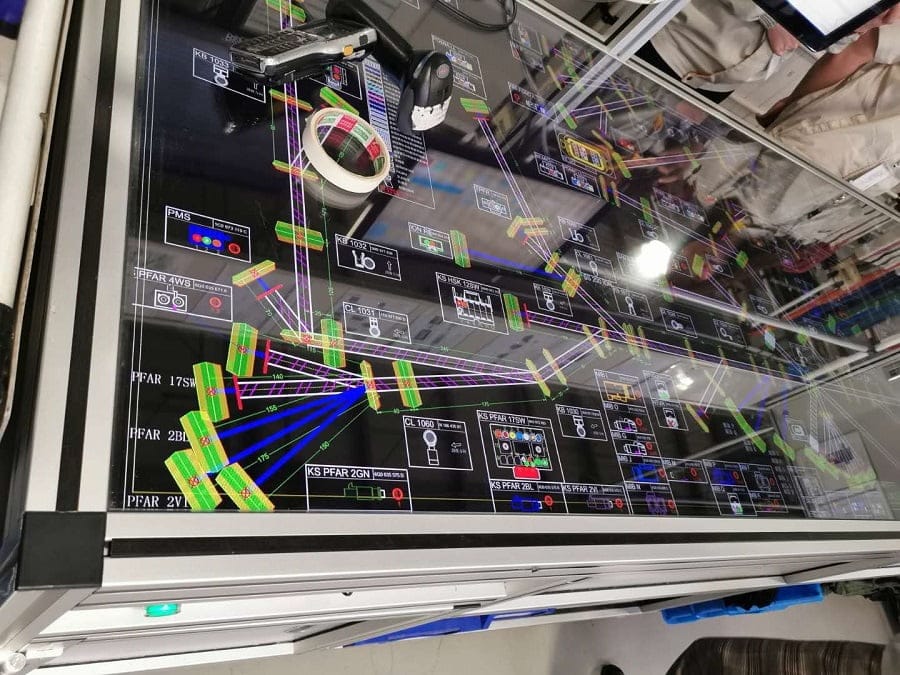

Mehr lesen "Grundlagen des Kabelbaumdesigns, Schritte, häufige Fehler, Ratschläge

Grundlagen des Kabelbaumdesigns, Schritte, häufige Fehler, Ratschläge Das Design eines elektrischen Kabelbaums ist möglicherweise einer der wichtigsten Schritte, die es ermöglichen, dass ein elektrisches Gerät funktioniert, insbesondere, dass ein Fahrzeug so funktioniert, wie es soll. Tatsächlich hängt der Erfolg einer Anwendung und ihre Beziehung zu den Kabeln und dem gesamten Stromfluss davon ab, wie gut ein Kabelbaum entworfen ist. Was ist ein Kabelbaum? Ein Kabelbaum ist eine Anordnung von Drähten oder elektrischen Kabeln zur Übertragung von Signalen oder elektrischem Strom. Die Drähte werden bei der Montage mit einem haltbaren Material wie z. B. einem Nylonband verbunden. Der Kabelbaum gewährleistet die Zuverlässigkeit der effektiven Energie- und Informationsübertragung in einer Anwendung. Es gibt also noch viel mehr, was wir Ihnen über Kabelbäume erzählen können, aber in diesem Artikel geben wir Ihnen einen grundlegenden Überblick, die Schritte, die Sie beim Entwurf und der Konstruktion leiten. Wo Kabelbäume verwendet werden Kabelbäume werden in einer Vielzahl von unterschiedlichen Umgebungen eingesetzt. In der Automobilindustrie, in der Luft- und Raumfahrt, bei militärischen Anwendungen, bei Konsumgütern und sogar bei privaten Projekten. In vielen dieser Anwendungen werden mehrere Kabelbäume verbaut, und viele davon sind für den effektiven Betrieb der Maschine, des Fahrzeugs oder des Produkts unerlässlich. Wann Kabelbäume installiert werden sollten Kabelbäume werden in einer Vielzahl von Projekten verwendet, die eine Vielzahl von Drähten und Kabeln enthalten und auf diese angewiesen sind, um verschiedene Aufgaben zu erfüllen. Die Herausforderung bei den meisten Kabelinstallationen besteht darin, dass die Kabel und Drähte selbst schwer zu organisieren und gerade und sauber zu halten sind. Ein Kabelbaum kann die Dinge besser organisieren und dabei helfen, das Projekt und die Installation einfacher zu installieren und für die gesamte Einheit...

Mehr lesen "Ein Leitfaden für den richtigen Kabelbaum im Auto

Ein Leitfaden für den richtigen Kabelbaum am Auto Jeder liebt ein auffälliges Äußeres am Auto. Schließlich ist es das, was uns auffällt, wenn wir ein Auto sehen. Gewindefahrwerke und glänzende Felgen sind zwar toll, aber eine Sache darf nicht übersehen werden: das Kabelsystem des Autos. Wenn der Kabelbaum Ihres Fahrzeugs nicht voll funktionsfähig ist, können Sie nicht das Beste aus Ihrem Auto herausholen, was es zu bieten hat. Sich zu vergewissern, dass Ihr Fahrzeug ordnungsgemäß verkabelt ist, kann wie eine beängstigende Aufgabe erscheinen, aber in Wahrheit brauchen Sie sich nicht einschüchtern zu lassen. Solange Sie geduldig sind und auf die Details achten, sind Sie in der Lage, eine gute Arbeit zu leisten. Hier sind einige Tipps, die Ihnen die Angst vor der Arbeit nehmen: Erstellen Sie einen Plan für die Verkabelung Bevor Sie mit dem Projekt beginnen, sollten Sie sich einen Plan für alle Schritte machen, die Sie vorhaben. Das bedeutet, dass Sie den Kabelbaum so auslegen müssen, dass Sie wissen, wo jedes Kabel hin soll. Gleichzeitig sollten Sie eine Vorstellung davon haben, wie viel Kabel für die gesamte Arbeit benötigt werden. Vielleicht möchten Sie auch jeden Kabelbaum beschriften, damit Sie die einzelnen Komponenten richtig zuordnen können. Stellen Sie alle für die Arbeit benötigten Werkzeuge zusammen. Das richtige Werkzeug erleichtert die Arbeit erheblich. Sie möchten nicht mit der Arbeit beginnen und dann feststellen, dass Ihnen eine Quetschzange, ein Lötkolben oder eine Abisolierzange fehlt. Außerdem benötigen Sie ein Ohm-Meter und eine Drahtbürste. Um zu prüfen, ob in einem Stromkreis Strom fließt, benötigen Sie eine Prüflampe. Ihre Anschlüsse müssen außerdem vor äußeren Einflüssen geschützt werden...

Mehr lesen "