النقطة الرئيسية لمراقبة الجودة في تسخير الأسلاك IPC620

بقلم تينا / 2024 年 10 نوفمبر 2024 月 2024 月 2024日

النقطة الرئيسية لمراقبة الجودة في تسخير الأسلاك IPC620

اتصل بنا للحصول على كتاب IPC620 النسخة الإنجليزية المطبوعة من IPC620

I. العمليات التي ينطوي عليها تصنيع الأسلاك

تشمل العمليات التي ينطوي عليها تصنيع الأحزمة السلكية على سبيل المثال لا الحصر:

- القطع: يشير إلى قطع الأسلاك أو الكابلات الإلكترونية إلى الطول المطلوب باستخدام الآلات أو يدوياً، دون الإضرار بالعزل أو الغلاف الخارجي.

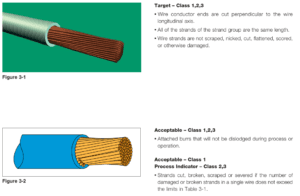

- تجريد الغلاف الخارجي: يشير الغلاف الخارجي عادةً إلى غلاف الكابل. يجب ألا تخدش آلة تجريد الغلاف الخارجي أو تقطع عزل الأسلاك الأساسية عند تجريد الغلاف الخارجي.

أي جروح أو كسور أو شقوق أو شقوق أو انقسامات في العازل (غير موضح).

u يتم تقليل سماكة العزل بأكثر من 20%.

u قطع غير مستوية أو ممزقة من العزل (أهداب وذيول وعلامات)

أكبر من 50% من القطر الخارجي للعزل أو

1 مم [0.039 بوصة] أيهما أكثر .

u العزل متفحم .

u يتم صهر العزل في خيوط السلك.

- تجريد الأسلاك الأساسية: اضبط آلة تجريد الأسلاك الأساسية على الحجم المطلوب للتجريد، واحرص على عدم خدش أو قطع الأسلاك النحاسية.

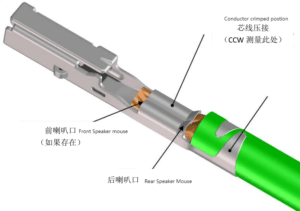

- العقص: حدد الشفرة المناسبة وفقًا لحجم الطرفية. قم بتجعيد السلك المحضر بجزء التجعيد الطرفي باستخدام الشفرة، مع التأكد من أن التجعيد محكم وأن مظهر وقوة سحب الطرف المجعد يفي بالمعايير.

- ضع الموصل: أدخل الأسلاك الطرفية المجعدة المؤهلة في مبيت الموصل المطابق. سيُسمع صوت نقرة واضحة عند إدخال الموصل بالكامل.

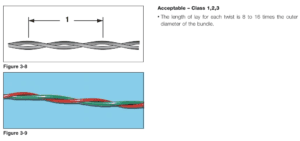

- لف الأسلاك: اضبط ماكينة لف الأسلاك على الارتفاع المناسب لضمان عدم تسطيح الأسلاك النحاسية أو تشابكها، وأن يكون الموصل الملتوي في شكل حلزوني موحد.

- التعليب: ضع التدفق على الأسلاك المحضرة ثم قم بتعليبها في حمام من القصدير. يجب أن يكون سطح الموصل مغطى بطبقة رقيقة من اللحام، ويجب أن تكون خيوط الموصلات واضحة، ويجب ألا يكون العزل محترقًا.

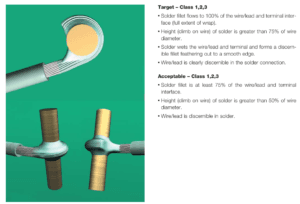

- اللحام: يشمل اللحام لحام القصدير واللحام بالموجات فوق الصوتية. ينطوي لحام القصدير على ملء المكونات الملحومة باللحام بالتساوي، دون وجود فراغات أو لحام بارد أو لحام كاذب.

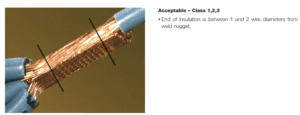

- يتضمن اللحام بالموجات فوق الصوتية وضع الموصل المطلوب على كتلة اللحام بالموجات فوق الصوتية. بعد اللحام، يجب أن يكون سطح الموصل على محيط كتلة اللحام ويجب ألا يكون هناك موصلات مفكوكة.

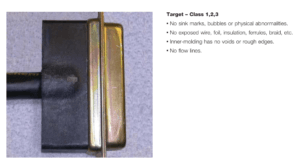

- قولبة مسبقة: قم بتركيب القالب المقابل على ماكينة التشكيل. يجب أن يكون السطح المقولب خاليًا من الفقاعات والانكماش والفراغات والنتوءات وعزل الموصلات المكشوفة أو الضفائر.

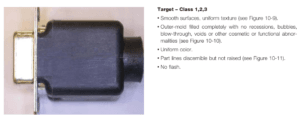

- القالب الخارجي: ابحث عن القالب المقابل وحدد اتجاه التشكيل بناءً على الرسم أو العينة. استيفاء متطلبات الرسم والمواصفات. يجب ألا يؤثر الشذوذ في المظهر على الشكل أو التجميع أو الوظيفة.

- الجدائل: استخدم ماكينة جدل لتثبيت الأسلاك المراد جدلها وضبطها على العدد المناسب من اللفات. يجب أن تكون درجة الجدائل 8-16 ضعف قطر السلك، ويجب أن يكون السطح خاليًا من العقد أو العيوب الأخرى.

- وضع الملصقات: ضع الملصقات وفقًا للأبعاد والموضع الموضح في الرسم أو العينة. وينبغي لف الملصق 1.5 لفة أو أكثر، مع إحكام لصقه، ويجب أن تكون الحواف متحاذية.

- الاختبار الكهربائي: ابحث عن تركيبات الاختبار المطابقة، واستخدم معلمات العينة لمعايرة الجهاز لضمان دقة كل دائرة، ثم اختبر الأسلاك النهائية واحدًا تلو الآخر.

ثانياً. نظرة عامة على نقاط مراقبة الجودة الرئيسية لتسخير الأسلاك

تشمل نقاط مراقبة الجودة الرئيسية للأحزمة السلكية بشكل أساسي القطع والتجريد والعقص والاختبار الكهربائي. تعتبر هذه النقاط حاسمة بالنسبة للوظائف الكهربائية الرئيسية للحزام السلكي لأنها تتعلق مباشرةً بقابلية استخدام الحزام، والتوصيل، والسلامة، والموثوقية.

وتشمل النقاط الأخرى ذات الأهمية الخاصة، اعتمادًا على حالة الإنتاج ومتطلبات المنتج، اللحام والقولبة والتعليب. وتتطلب هذه النقاط أيضًا رقابة صارمة لضمان الجودة الشاملة لتسخير الأسلاك.

أهمية نقاط التحكم الرئيسية

القطع:

القطع هو الخطوة الأولى في إنتاج الأحزمة السلكية ويحدد الطول والمظهر النهائي للحزام. وتحدد دقة القطع الفعالية الإجمالية للحزام والتقدم السلس للمعالجة اللاحقة، مما يؤثر بشكل كبير على عملية التصنيع بأكملها.

تجريد الأسلاك الأساسية:

تكمن أهميته في إزالة طبقة العزل بالكامل دون إتلاف الأسلاك النحاسية الداخلية. ستؤثر الأسلاك النحاسية المكسورة على قدرة حمل التيار وقد لا تفي بالحد الأدنى من نطاق حمل التيار. كما سيؤثر ذلك على الأداء الكهربائي لحزمة الأسلاك، مما يؤدي إلى حدوث دوائر قصيرة أو دوائر مفتوحة. ويمكن أن يؤثر أيضًا على العمليات اللاحقة، مما يؤثر على سير عملية الإنتاج بأكملها. الأسلاك النحاسية هي المكوّن الموصّل الرئيسي، وأي تلف سيؤثر بشكل مباشر على الأداء الكهربائي لمجموعة الأسلاك.

العقص:

العقص هو عملية ربط السلك والطرف معاً. يتم إجراء اختبار قوة السحب للتأكد من صلابة تجعيد السلك (راجع جدول اختبار قوة السحب). قد تؤدي قوة السحب غير الكافية إلى الارتخاء أو الانفصال أثناء الاستخدام اللاحق، مما يؤدي إلى دوائر مفتوحة وانقطاع كهربائي. ستؤدي قوة السحب المفرطة إلى تشويه الطرفية، مما يؤدي إلى سوء مظهر الطرفية واحتمال تلف الأسلاك النحاسية، مما يؤدي إلى الكسر أثناء الاستخدام اللاحق. يتم إجراء تحليل المقطع العرضي للتحقق من التوزيع المنتظم للأسلاك النحاسية عند تجعيد الموصل الطرفي وضمان وجود مساحة تلامس كافية لتوصيل جيد.

الاختبار الكهربائي:

الاختبار الكهربائي عبارة عن عملية فحص شاملة لضمان صحة وتوصيل كل دائرة في مجموعة الأسلاك. ويضمن أن كل جزء من مجموعة الأسلاك يفي بمتطلبات الأداء الكهربائي، بما في ذلك المقاومة والتوصيل وصحة الدائرة. يتطلب كل منتج اختبار كهربائي 100% لضمان موثوقية المنتج وصحته.