منطق تصميم الكابل الملفوف

بقلم تينا / 2024 年 10 نوفمبر 2024 月 2024 月 2024日

تصميم الكابلات الملفوفة وتصنيعها وحساب طولها واحتياطاتها

1. ما هو الكابل الملفوف؟

الكابل الملفوف، والمعروف أيضاً باسم السلك الملفوف القابل للسحب أو الكابل الحلزوني، هو نوع من الكابلات الكهربائية التي يمكن أن تمتد وتتراجع مثل اللفائف.

النموذج الأولي للكابل الملفوف هو في الواقع كابل مستقيم. يتم لف الكابل المستقيم حول قضيب رقص ثابت الحجم عن طريق اللف، وتستخدم المشابك على كلا الجانبين لتثبيت السلك. ثم يوضع في الفرن ويُخبز لفترة زمنية معينة. يتم إخراجه لتشكيل كابل ملفوف.

2. حساب الطول الحقيقي للكابل الملفوف

1. تحديد الهيكل:

فهم عدد المقاطع الملفوفة والمقاطع المستقيمة التي يتكون منها الكابل الملفوف.

2. قياس معلمات الملف:

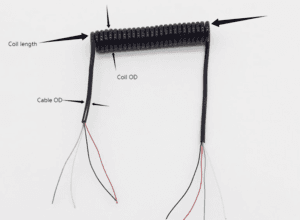

طول الملف: نحتاج إلى أن يكون طول الجزء الملفوف واضحًا، من كابل ملفوف من جهاز كمبيوتر واحد

طول=350 مم

معرّف الملف: قياس الجزء الملفوف OD=15 مم تحدد هذه المعلمة OD لعصا التثبيت

العمق الخارجي للملف: قياس العمق الخارجي للجزء الملفوف = 25 مم

OD للكابل: قياس OD للكابل 5.0 مم

ثم يمكننا معرفة عدد لفائف الكابل الملفوفة كم عدد اللفائف. استخدم طول الجزء الملفوف/أسلاك OD 350/5.0=70 ملفًا

بحساب طول الملف الواحد = πD= 3.14 × (25 مم - 5.0 مم) = 62.8 مم (لأننا لا نستطيع استخدام الحد الأقصى للعمق الخارجي لحساب المحيط)

1 ملف 62.8 مم × 70 ملفًا = 4396 مم + أطوال الطرفين هي الطول الحقيقي لكابل الكمبيوتر الواحد

لاحظ أن طريقة القياس بسيطة وبديهية نسبيًا وبديهية ولكنها قد تحتوي على بعض الأخطاء. تتطلب طريقة حساب الصيغة قياسًا دقيقًا للمعلمات الهيكلية للكابل الملفوف، والنتيجة المحسوبة ليست سوى نتيجة تقريبية. في الحسابات العملية، اختر الطريقة المناسبة بناءً على الموقف المحدد.

4. اتجاه الجزء المستقيم للكابل الملفوف على كلا الجانبين

اتجاهات الخروج الرئيسية للكابلات الملفوفة هي كما يلي:

I. مخرج مستقيم - 180 درجة مع الجزء الملفوف

يمتد الكابل الملفوف مباشرة من أحد طرفيه. اتجاه الخروج هذا هو الأكثر شيوعًا وبديهية، وهو مناسب للحالات التي تتطلب تخطيطًا مكانيًا أنيقًا، مثل كابلات البيانات للمنتجات الإلكترونية التي تمتد مباشرة من جانب الجهاز لسهولة التوصيل بالمعدات الخارجية.

II. مخرج متعدد الزوايا - عمودي مع الجزء الملفوف

مخرج مائل: يمتد الكبل الملفوف بزاوية مائلة معينة. في بعض سيناريوهات الاستخدام الخاصة، بسبب وضع الجهاز أو متطلبات الاستخدام، قد يحتاج الكبل الملفوف إلى الخروج بشكل مائل للتكيف بشكل أفضل مع قيود المساحة أو عادات التشغيل.

مخرج منحني: يمكن أن يظهر الكابل الملفوف بشكل منحني معين أثناء امتداده. على سبيل المثال، في بعض الأجهزة القابلة للارتداء، قد يخرج الكابل الملفوف في بعض الأجهزة القابلة للارتداء، بطريقة منحنية ليتوافق مع منحنيات جسم الإنسان أو يتكيف مع الهيكل الخاص للجهاز، مما يضمن ثبات التوصيل وراحة الارتداء.

5. عملية تصنيع الكابلات الملفوفة

تختلف عملية تصنيع الكابلات الملفوفة باختلاف المواد والاستخدام المقصود. وتتم العملية العامة على النحو التالي:

تحضير المواد:

اختر مواد الغلاف السلكي المناسبة، مثل TPR/TPE/PU/PVC، إلى جانب اللفائف والملحقات الأخرى.

التغليف:

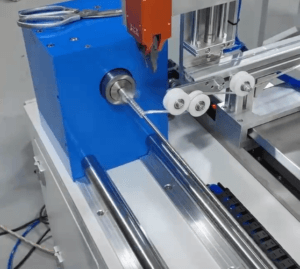

قم بلف السلك حول قضيب اللف مع الانتباه إلى إحكام اللف وتوحيده.

الخَبز:

ضع قضيب الجرح في حجرة الخبز لضبط شكل السلك. تعتمد درجة حرارة الخبز والوقت اللازم للخبز على مادة ومواصفات السلك.

التبريد:

قم بإزالة الكابل الملفوف المخبوز واتركه ليبرد. يمكن القيام بذلك من خلال التبريد الطبيعي أو التبريد القسري باستخدام مروحة أو معدات أخرى.

الرجوع إلى الوراء

قم بعكس الكابل الملفوف المبرد لزيادة مرونته ومتانته.

الخبز الثاني:

ضع الكابل الملفوف المعكوس مرة أخرى في حجرة الخَبز لمزيد من الخَبز لضبط شكل السلك بشكل أكبر.

التبريد والتشكيل:

قم بإزالة الكابل الملفوف المخبوز واتركه ليبرد ويضبط شكله النهائي. يمكن أن يتم ذلك من خلال التبريد الطبيعي أو التبريد القسري باستخدام مروحة أو معدات أخرى.

الاختبار:

اختبر الكابل الملفوف النهائي، بما في ذلك اختبار الشد واختبار المرونة واختبار المتانة، للتأكد من أن جودته تفي بالمتطلبات.

من المهم أن نلاحظ أن عملية تصنيع الكابلات الملفوفة تتطلب رقابة صارمة على معايير مثل درجة الحرارة والوقت والضغط لضمان الجودة والأداء. كما يجب اتخاذ احتياطات السلامة أثناء عملية التصنيع لمنع وقوع الحوادث.

6. الفوائد الرئيسية للكابلات الملفوفة هي:

قابلية الانكماش:

يمكن تمديدها إلى أطوال مختلفة حسب الحاجة وسحبها تلقائياً عند عدم استخدامها، مما يوفر المساحة ويسهل حملها وتخزينها. على سبيل المثال، عند استخدام سماعات الرأس أو كابلات البيانات، فهي تمنع التشابك ويسهل تخزينها.

متانة عالية:

وهي مصنوعة من مواد عالية الجودة وتصميم هيكلي معقول، ويمكنها تحمل قدر معين من قوة الشد ودورات الانحناء، ولا تتلف بسهولة، ولها عمر خدمة طويل. وهي مناسبة بشكل خاص لتوصيل الأجهزة التي يتم نقلها أو استخدامها بشكل متكرر.

المرونة:

يمكن أن تتكيف مع بيئات الاستخدام المختلفة وزوايا الانحناء، ولا يمكن كسرها بسهولة، ويمكن استخدامها بمرونة حتى في المساحات الضيقة أو سيناريوهات الاستخدام المعقدة.

مجموعة واسعة من التطبيقات:

نظرًا لخصائصها الفريدة، تُستخدم الكابلات الملفوفة على نطاق واسع في الأجهزة المحمولة مثل السيارات والآلات والأدوات، وكذلك في المعدات الميكانيكية والأجهزة الإلكترونية وبناء التعدين والمرافق الأرضية للمطارات وغيرها من المجالات. في هذه المجالات، فإن قابلية التمدد والمرونة العالية للكابلات الملفوفة تجعلها خيارًا مثاليًا، خاصةً عندما تحتاج الكابلات إلى الثني أو التمدد أو التعرض للإجهاد الميكانيكي بشكل متكرر.

7. اختيار الغلاف الخارجي للكابل الملفوف: PVC، TPE، TPU، TPU - وصف المزايا والعيوب

في الكابلات الملفوفة، لكل من مواد الغلاف الخارجي PVC و TPE و TPU مزايا وعيوب. إليك مقدمة مفصلة:

كلوريد البوليفينيل المتعدد الفينيل (PVC)

مثبط جيد للهب والعزل: يمنع بفعالية مشاكل السلامة مثل الحرائق الناجمة عن الدوائر الكهربائية القصيرة، مما يضمن الاستخدام الآمن، ويستخدم بشكل شائع في تغليف الأسلاك والكابلات. على سبيل المثال، في كابلات توصيل الأجهزة الداخلية العادية، توفر الكابلات البلاستيكية الملفوفة حماية جيدة للعزل.

مقاومة جيدة للأحماض والزيوت: يمكن أن تقاوم التآكل من الأحماض والزيوت والمواد الكيميائية الأخرى إلى حد معين، مما يجعلها مناسبة للبيئات التي قد تتلامس مع المواد الكيميائية الخفيفة. على سبيل المثال، غالبًا ما يُستخدم في كابلات توصيل المعدات بالقرب من المواد الكيميائية غير المسببة للتآكل الشديد في المصانع.

سهل المعالجة والتعديل، منخفض التكلفة: تكنولوجيا معالجة بسيطة نسبيًا، ويمكن تعديل مرونتها وصلابتها بإضافة مواد ملدنة مختلفة لتلبية الاحتياجات المختلفة. سعر المواد الخام منخفض نسبيًا، مما يقلل من تكاليف الإنتاج. على سبيل المثال، في الإنتاج على نطاق واسع مع متطلبات التحكم في التكلفة العالية، تعتبر الكابلات البلاستيكية الملفوفة خيارًا أكثر اقتصادا.

TPE (اللدائن البلاستيكية الحرارية)، TPU، PE

المزايا

مرونة ممتازة ومقاومة ممتازة للتآكل:

تتمتع بمرونة ممتازة، ويمكنها العودة بسرعة إلى شكلها الأصلي بعد التمدد أو الثني، وتتمتع بمقاومة جيدة للتآكل، مما يسمح باستخدامها على المدى الطويل دون فقدان الأداء. إنه مناسب جدًا للكابلات الملفوفة التي تتطلب التمدد والثني المتكرر، مثل كابلات سماعات الأذن وكابلات البيانات.

ملمس ناعم:

ناعم الملمس، مريح الملمس، قابل للتكيف مع مختلف الأشكال وظروف الضغط، ولا يسبب أي إزعاج أثناء الاستخدام.

مقاومة جيدة للمواد الكيميائية:

يمكن أن يقاوم التآكل من المذيبات والوقود والمواد الكيميائية المختلفة، ويتمتع بثبات جيد، ومناسب للبيئات التي قد تتلامس مع مواد كيميائية مختلفة.

انكماش منخفض:

معدل انكماش منخفض، ومناسب لإنتاج منتجات عالية الدقة، ويمكنه ضمان ثبات الأبعاد واتساق الكابلات الملفوفة.

تقنية المعالجة البسيطة:

يمكن معالجتها من خلال طرق مختلفة مثل التشكيل بالحقن والبثق والتقويم، مما يؤدي إلى كفاءة إنتاج عالية وتكاليف معالجة منخفضة نسبيًا.

8. جودة الكابلات الملفوفة

يمكن تقييم جودة الكابلات الملفوفة من الجوانب التالية:

I. جودة المظهر

مادة الغلاف الخارجي: يجب أن تكون أغلفة الكابلات الملفوفة عالية الجودة ناعمة وخالية من العيوب الواضحة وخالية من التحبب. يجب أن تكون أغلفة PVC ذات لون موحد وخالية من البقع السوداء أو الشوائب. يجب أن تتمتع أغلفة TPE وTPU بمرونة ونعومة جيدة وسطح أملس.

انتظام قطر السلك: يجب أن يكون قطر السلك موحدًا ومتسقًا، دون تفاوت في السماكة. لا يؤثر ذلك على المظهر فحسب، بل يتعلق أيضًا باستقرار أداء الكابل الملفوف.

جودة الموصل: يجب أن يكون الموصل ثابتًا وآمنًا ومتصلًا بإحكام بالجسم الرئيسي للكابل الملفوف. يجب أن تكون الموصلات المعدنية خالية من الصدأ والأكسدة، ويجب أن تكون الموصلات البلاستيكية خالية من التشققات والتشوهات.

ثانياً. جودة الأداء

قابلية السحب: هذه خاصية أداء رئيسية للكابلات الملفوفة. وينبغي أن تتمتع الكابلات الملفوفة عالية الجودة بأداء جيد قابل للسحب، وأن تكون قادرة على التمدد بسهولة إلى الطول المطلوب، والعودة بسرعة إلى شكلها الأصلي بعد التحرير، والحفاظ على الأداء بعد عمليات التمدد المتعددة.

المرونة: الكابلات الملفوفة ذات المرونة الجيدة لا تتشوه بسهولة أثناء الاستخدام ويمكنها الحفاظ على طول وشكل ثابتين. يمكن الحكم على جودة المرونة من خلال تمديد الكابل الملفوف وملاحظة سرعة الارتداد ودرجته.

المتانة: تشمل قوة الشد وأداء الانحناء ومقاومة التآكل. يجب أن يكون قادرًا على تحمل قدر معين من الشد والانحناء دون أن ينكسر، ويجب ألا يتآكل الغلاف الخارجي بسهولة تحت الاستخدام والاحتكاك المتكرر.

التوصيلية: إذا كان الكابل الملفوف يستخدم لنقل التيار أو الإشارات، فيجب أن يكون موصلية جيدة. يمكن الحكم على التوصيلية بقياس قيمة المقاومة لتحديد ما إذا كانت تفي بالمتطلبات.

باختصار، يمكن الحكم على جودة الكابلات الملفوفة من خلال النظر بشكل شامل في مظهرها وأدائها وجوانب السلامة فيها. عند اختيار الكابلات الملفوفة، اختر المنتجات الموثوقة بناءً على الاحتياجات الفعلية لضمان الفعالية والسلامة.