تستخدم شركة QL-Custom Technology تقنية الحقن الرأسي في القولبة بالحقن لمساعدة العملاء على إيجاد حلول للقطع الحقيقية، بدءًا من اختيار البلاستيك والنماذج الأولية السريعة إلى الإنتاج بكميات كبيرة. تمتلك الشركة قدرات إبداعية ذاتية في إنتاج الأدوات واستخدام الأدوات مع بلاستيك مصبوب بالحقن الأجزاء والمكونات.

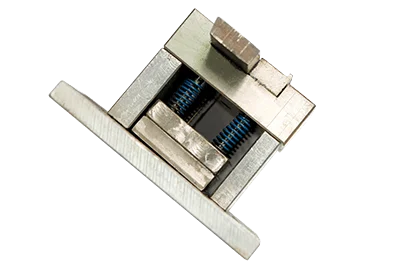

>> أداة التشكيل العمودي >> أداة التشكيل العمودي

أدوات القوالب مصممة فقط لماكينات القولبة بالحقن الحامل (العمودية):

- اتجاه فوهة القالب لأعلى موجه نحو الأعلى

- 1 ~ 12 تجاويف متاحة للطلقات

- العمر الافتراضي للإنتاج بكميات كبيرة 100,000 إلى 200,000 لقطة

- إيقاف التشغيل التلقائي

- تمت إضافة وحدة التحكم في درجة حرارة أداة القالب OEM

قولبة الحقن عند درجة حرارة معينة، من خلال برغي التحريك اللولبي للمواد البلاستيكية المنصهرة تمامًا، مع حقن ضغط عالٍ في تجاويف القالب، بعد التبريد والمعالجة، للحصول على طريقة الأجزاء. هذه الطريقة مناسبة للإنتاج الضخم للأجزاء المعقدة. المزايا بما في ذلك سرعة الإنتاج، والكفاءة العالية، ويمكن أن تكون العملية آلية، وأصناف الألوان، ويمكن أن يكون الشكل من البسيط إلى المعقد، ويمكن أن تكون الأبعاد كبيرة إلى صغيرة، وحجم المنتج دقيق، وسهل استبدال المنتج، ويمكن أن تشكل أجزاء معقدة، وقولبة الحقن لعدد كبير من الإنتاج والمنتجات المعقدة هي الكفاءة. يخدم هذا القولبة حاليًا الموصلات والصناعات الإلكترونية وتخفيف الكابلات والمقابس البلاستيكية والمفاتيح ومجموعة متنوعة من المنتجات البلاستيكية بجانب حياتنا.

>> تحليل عيوب المنتجات >> تحليل عيوب المنتجات

تتنوع عملية التشكيل بالحقن المستخدمة في مجموعة متنوعة من المواد الخام البلاستيكية، ويتنوع تصميم القالب لأنواع وأشكال القوالب، بالإضافة إلى ذلك، فإن تشغيل العمال لدرجة معينة من الإلمام بآلة التشكيل بالحقن والعمال بين مهارات التشغيل، كما تختلف اختلافات الخبرة العملية، وفي الوقت نفسه، فإن البيئة الموضوعية (مثل درجة الحرارة المحيطة والرطوبة ونظافة الهواء) تختلف مع الفصول، وهذه الظروف الموضوعية والذاتية معًا تحدد عيوب التشكيل بالحقن، وبشكل عام، فإن تقييم أداء المنتجات البلاستيكية له ثلاثة جوانب بشكل أساسي:

- مظهر الجودة، بما في ذلك السلامة واللون واللمعان;

- الدقة بين الحجم والموضع النسبي، أي دقة الأبعاد ودقة الموضع;

- مع استخدام الخواص الميكانيكية المقابلة والخصائص الكيميائية والخصائص الكهربائية والأداء.

إذا كانت هناك مشكلة بسبب أي من الجوانب الثلاثة المذكورة أعلاه، فسيؤدي ذلك إلى إنتاج وتوسيع عيوب المنتج.

ملخص تصنيف العيوب الشائعة في منتجات القولبة بالحقن

عيوب المظهر: تغير اللون، وعلامات اللحام

مشاكل العملية: الومضات، والانكماش، ونقص الراتنجات

مشاكل العملية: تشوه وهشاشة