الشركة المصنعة للأسلاك

بقلم تينا / 2021 / 2021 月 2021 月 2021 月 2021 月 2021 月 2021 月 2021

الشركة المصنعة للأسلاك

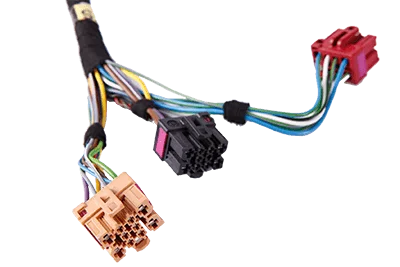

تحتل شركة QL-Custom Technology Limited موقع الصدارة في مجال تصنيع الأحزمة السلكية، حيث تتخصص في إنتاج مجموعة متنوعة من المنتجات، بما في ذلك مجموعات الأحزمة السلكية والأحزمة السلكية وحلول الأحزمة السلكية والأحزمة السلكية المخصصة. وتمتد كفاءتنا لتشمل التصنيع الدقيق للأغلفة الواقية المصنوعة من مواد حرارية أو بلاستيكية حرارية. تلعب هذه الأغلفة الواقية دورًا محوريًا في حماية الأسلاك الكهربائية من المخاطر البيئية والتآكل والتلف المحتمل.

نتميز بالتزامنا الثابت بمعايير الجودة الصارمة، ونفخر بتقديم أحزمة الأسلاك المخصصة مصممة لمختلف التطبيقات في مختلف الصناعات مثل الصناعات الإلكترونية والطبية والسيارات والاتصالات السلكية واللاسلكية والعسكرية والطاقة النظيفة وغيرها من القطاعات عالية الدقة. وباعتبارنا شركة تصنيع تعاقدية عالمية متميزة، فإن حلولنا المبتكرة تلبي الاحتياجات الفريدة لمصنعي المعدات الأصلية والشركات في قطاعات متنوعة.

في شركة QL-Custom Technology Limited، يمتد تخصصنا إلى كابل مقولب بشكل زائد التجميعات والأسلاك، مما يضمن أعلى مستوى من الحماية للأسلاك. تشمل مجموعتنا الشاملة من العروض التي نقدمها تجميعات الأسلاك وكابلات البطاريات وتجميعات الكابلات المخصصة المصممة خصيصاً لتلبية المتطلبات المحددة لعملائنا.

مدعومين بقوى عاملة عالمية متفانية وذات خبرة عالية، نفخر بريادتنا في هذه الصناعة، حيث نقدم خدمات ذات قيمة مضافة مثل صب البلاستيك، والقولبة بالضغط المنخفض (صب ثنائي الفينيل متعدد الكلور فوق القوالب)، وحلول بناء الصناديق. تمتد خبرتنا الشاملة لتشمل مجالات مختلفة، بما في ذلك على سبيل المثال لا الحصر نقل البيانات، ومحطات التجعيد، والألياف الضوئية، والألياف البصرية.

سواء كان الأمر يتعلق بتلبية متطلبات تقنيات القيادة الآلية المتطورة، أو تسهيل تركيب معدات الطاقة الشمسية، أو توفير حلول للإلكترونيات الاستهلاكية، فإن شركة QL-Custom Technology Limited هي شريكك الموثوق. نحن ملتزمون بتقديم حلول تجميع الأسلاك والكابلات من الدرجة الأولى التي تتماشى مع الاحتياجات المتطورة للصناعة.

اختر شركة QL-Custom Technology Limited للحصول على أحدث التقنيات والمنتجات الموثوقة والالتزام بالتميز في كل جانب من جوانب تصنيع الأسلاك. تلبي مجموعتنا الواسعة من العروض التي نقدمها المتطلبات الفريدة لمختلف الصناعات، وتوفر حلولاً للأسلاك والكابلات والأسلاك التي تلبي أعلى معايير الجودة.

تضمن قوتنا العاملة العالمية أننا مجهزون جيداً للتعامل مع التحديات المتنوعة، بما في ذلك المخاطر البيئية. وباعتبارنا شركة تصنيع تعاقدية عالمية، فإننا نقدم خدمات ذات قيمة مضافة، بما في ذلك اللحام بالموجات فوق الصوتية، لتلبية المتطلبات المعقدة لعملائنا. تدعوك QL-Custom Technology Limited، الاسم المرادف للجودة والابتكار في تصنيع أحزمة الأسلاك، إلى تجربة التميز المصمم خصيصاً لتلبية احتياجاتك الخاصة.

ما هي وصلة الأسلاك؟

الحزام السلكي، الذي يُشار إليه أيضًا باسم حزام الأسلاك أو مجموعة حزام الأسلاك أو مجموعة حزام الأسلاك، هو مجموعة شاملة ومنظمة من الأسلاك الكهربائية والكابلات والمكونات المرتبطة بها التي تخدم الغرض الأساسي لنقل الطاقة الكهربائية والإشارات داخل نظام أو جهاز. يتم تصميم هذه الأحزمة بدقة لتسهيل التوصيل الفعال مع ضمان التنظيم والحماية من المخاطر البيئية.

تجد أحزمة الأسلاك تطبيقات واسعة النطاق في مختلف الصناعات، بما في ذلك السيارات والفضاء والإلكترونيات الاستهلاكية والمعدات الشمسية وغيرها. فهي تلعب دورًا محوريًا في ربط المكونات الكهربائية، حيث توفر مسارًا منظمًا لتدفق الكهرباء والإشارات. أحزمة الأسلاك المخصصة هي حلول مصممة خصيصًا لتلبية المواصفات والمتطلبات الفريدة لمصنعي المعدات الأصلية (OEMs) العاملين في قطاعات مختلفة.

تشتمل حلول الأسلاك هذه على مجموعة متنوعة من العناصر، مثل الأسلاك الكهربائية وكابلات البطاريات وأطراف التجعيد والألياف الضوئية والمكونات الأساسية الأخرى. يضمن تكامل تقنيات التصنيع المتقدمة، بما في ذلك اللحام بالموجات فوق الصوتية، توصيلات آمنة وموثوقة تتحمل التحديات التي تفرضها الظروف البيئية.

فوائد حلول تسخير الأسلاك

الدقة والتنظيم:

- تضمن أحزمة الأسلاك ومجموعات الأسلاك توجيه الأسلاك الكهربائية بشكل منظم، مما يعزز كفاءة النظام بشكل عام.

- تضمن خبرة QL-Custom في تصنيع الأحزمة الدقة في ترتيب الكابلات والأسلاك.

تعدد الاستخدامات عبر الصناعات:

- تلبي تجميعات الأسلاك احتياجات مجموعة متنوعة من الصناعات، بما في ذلك السيارات ومعدات الطاقة الشمسية والإلكترونيات الاستهلاكية وغيرها.

- توفر مجموعات الكابلات المخصصة حلولاً متعددة الاستخدامات للمتطلبات الفريدة لمختلف القطاعات.

اتصال موثوق:

توفر وصلات الأسلاك وحلول الكابلات من QL-Custom اتصالاً موثوقاً في مختلف التطبيقات، مما يضمن سلاسة العمليات.

تساهم مجموعات التسخير في استقرار التوصيلات الكهربائية في الأنظمة الحرجة.

حلول مصممة خصيصاً لمصنعي المعدات الأصلية:

- تستفيد الشركات المصنعة للمعدات الأصلية (OEMs) من الأسلاك المصممة لتلبية احتياجاتها الخاصة.

- QL-Custom هي شريك موثوق به لمصنعي المعدات الأصلية الذين يبحثون عن تجميعات الكابلات وحلول الأسلاك عالية الجودة.

الكفاءة في نقل البيانات:

- تدعم الألياف الضوئية المدمجة في مجموعات الأسلاك نقل البيانات عالية السرعة في الاتصالات والقطاعات الأخرى.

- تساهم حلول QL-Custom في نقل البيانات بكفاءة، وتلبية متطلبات التقنيات الحديثة.

المتانة البيئية:

- تم تصميم تجميعات الكابلات المخصصة ومجموعات الأسلاك لتتحمل الظروف البيئية، مما يضمن طول العمر والموثوقية.

- تستفيد تركيبات معدات الطاقة الشمسية من حلول الأسلاك المتينة القادرة على تحمل الظروف الجوية المختلفة.

التكامل السلس في القيادة الآلية:

- تلعب مجموعات الأسلاك ذات أطراف التجعيد دورًا حيويًا في التكامل السلس للمكونات الكهربائية في تقنيات القيادة الآلية.

- تساهم حلول QL-Custom في الدقة والموثوقية المطلوبة لأنظمة السيارات المتقدمة.

الخبرة العالمية في مجال التصنيع التعاقدي:

- تقدم QL-Custom، بصفتها شركة تصنيع تعاقدية عالمية، خبرة في حلول بناء الصناديق، مما يضمن الدعم الشامل للعملاء في جميع أنحاء العالم.

- تكرس القوى العاملة العالمية للشركة جهودها لتقديم وصلات الأسلاك وتجميعات الكابلات عالية الجودة.

ضمان الجودة:

- تلتزم جميع وصلات الأسلاك، ومجموعات الأسلاك، وتجميعات الكابلات بأعلى معايير الجودة التي وضعتها شركة QL-Custom Technology Limited.

- يضمن الالتزام بالجودة حصول العملاء على منتجات تلبي توقعات الصناعة أو تتجاوزها.

الخدمات ذات القيمة المضافة:

- تتجاوز QL-Custom حدود التصنيع الأساسي، حيث تقدم خدمات ذات قيمة مضافة تعزز القيمة الإجمالية لحلول الأسلاك.

- يستفيد العملاء من الدعم الشامل، بما في ذلك مشورة الخبراء والحلول المصممة خصيصاً لتلبية احتياجاتهم الخاصة.

استخدامات تسخير الأسلاك

تقنيات القيادة الآلية:

- تضمن مجموعات الأسلاك وحلول الأسلاك نقل البيانات بدقة في أنظمة القيادة الآلية.

- تدعم مجموعات الأسلاك وتجميعات الكابلات المخصصة مع أطراف التجعيد الاحتياجات الكهربائية المعقدة للمركبات الآلية.

معدات الطاقة الشمسية:

- تلعب الأسلاك دورًا حاسمًا في توصيل الألواح الشمسية، مما يسهل تسخير الطاقة بكفاءة.

- تضمن مجموعات الكابلات المخصصة المصممة للتطبيقات الشمسية اتصالاً موثوقاً في مختلف الظروف البيئية.

الإلكترونيات الاستهلاكية:

- تم تصميم الأسلاك ومجموعات الكابلات لتلبية المتطلبات المعقدة للأجهزة الإلكترونية الاستهلاكية.

- تعمل الأسلاك على تنظيم الأسلاك الكهربائية، مما يساهم في سلاسة عمل المنتجات الإلكترونية.

الاتصالات السلكية واللاسلكية:

- تتيح الألياف الضوئية المدمجة في مجموعات الأسلاك نقل البيانات عالية السرعة في البنية التحتية للاتصالات السلكية واللاسلكية.

- تلبي حلول الكابلات المخصصة الاحتياجات المحددة لصناعة الاتصالات السلكية واللاسلكية.

المعدات الطبية:

- تُستخدم مجموعات الأسلاك في الأجهزة الطبية، مما يوفر توصيلات كهربائية منظمة وموثوقة.

- تساهم أحزمة الأسلاك في دقة وكفاءة المعدات الطبية.

الطاقة النظيفة:

- تلعب الأسلاك دوراً في توصيل المكونات في أنظمة الطاقة النظيفة، مما يضمن الأداء الأمثل.

- تدعم مجموعات الكابلات المخصصة المتطلبات الكهربائية المتنوعة لمبادرات الطاقة النظيفة.

قطاعات صناعية متنوعة:

- تجد الأحزمة السلكية تطبيقات في مختلف القطاعات غير قطاع السيارات والإلكترونيات.

- تقدم شركة QL-Custom، بصفتها شركة تصنيع تعاقدية عالمية، حلولاً لمصنعي المعدات الأصلية في مختلف الصناعات.

نقل البيانات:

- تساهم الألياف البصرية وأسلاك الأسلاك في نقل البيانات بكفاءة في مختلف التطبيقات.

- تم تصميم الأسلاك المخصصة لتلبية احتياجات نقل البيانات لمختلف القطاعات.

الخدمات ذات القيمة المضافة:

- تقدم شركة QL-Custom Technology Limited خدمات ذات قيمة مضافة، بما في ذلك حلول بناء الصناديق، بما يضمن الدعم الشامل.

- تلتزم القوى العاملة العالمية في QL-Custom بتقديم التميز وتلبية المتطلبات المحددة للعملاء.

معايير الجودة:

- تلتزم جميع وصلات الأسلاك ومجموعات الأسلاك وتجميعات الكابلات بأعلى معايير الجودة.

- تفخر شركة QL-Custom Technology Limited بالدقة والموثوقية المتجسدة في منتجات الشركة.

حلول مخصصة لقطاعات أخرى:

- تم تصميم الأحزمة وتجميعات الكابلات المخصصة لتلبية الاحتياجات الفريدة لمختلف القطاعات.

- بصفتها شركة رائدة في مجال التصنيع التعاقدي، تقدم QL-Custom حلولاً مصممة خصيصاً لمختلف الصناعات.

الطاقة الإنتاجية لأفضل الشركات المصنعة

يمكن لمصنعي أحزمة الأسلاك العمل مع مصنعي المعدات الأصلية الصغيرة والكبيرة؛ ويمكننا التعامل مع الطلبات الفردية أو احتياجات الإنتاج والتجميع المستمرة. كما يمكننا أيضًا زيادة الإنتاج لتلبية احتياجات عملائنا، ولدينا سمعة طيبة في التسليم في الوقت المحدد وسرعة الإنجاز، حتى في طلبات الأحزمة المخصصة.

وكما هو الحال بالنسبة لخدماتنا، فإننا نركز على ضمان الجودة ومراقبة الجودة كجانب أساسي من جوانب تصميم الأسلاك والكابلات المخصصة. كما أن القدرة على إكمال تجميع مجموعة الأسلاك والكابلات هي فائدة إضافية لعملائنا، مما يسمح بتصنيع أسرع وتقليل مخاطر الخطأ البشري أثناء توصيل الأسلاك في الموقع لمكون أو نظام أو جهاز.

نحن نختلف عن الشركات الأخرى المصنعة لأحزمة الأسلاك المخصصة، والأسباب هي:

بحثنا عن أفضل الحلول

لدينا خبرة واسعة في العمل كفريق عمل مخصص الشركة المصنعة لتجميع الكابلاتعبر مجموعة واسعة من الصناعات المتنوعة. نحن نوفر تجميعات كابلات مخصصة لقطاع المعدات الزراعية، ومصنعي الأجهزة الطبية، والجيش، والمصاعد، وأجهزة التحكم الصناعية، على سبيل المثال لا الحصر.

تسمح هذه الخبرة لفريقنا بتحديد أفضل الحلول الممكنة في تجميعات الكابلات المخصصة للاستفادة من التطبيق المحدد.

القدرة على التسليم في الوقت المحدد

تُعد المواعيد النهائية للإنتاج لكل من الطلبات الصغيرة والكبيرة الحجم أولوية دائمًا في شركة حلول التجميع. نحن نتمتع بسمعة طيبة في تسليم عملائنا في الوقت المحدد وحسب الطلب، مما يضمن عدم انتظار قطع الغيار والمكونات من شركة حلول التجميع.

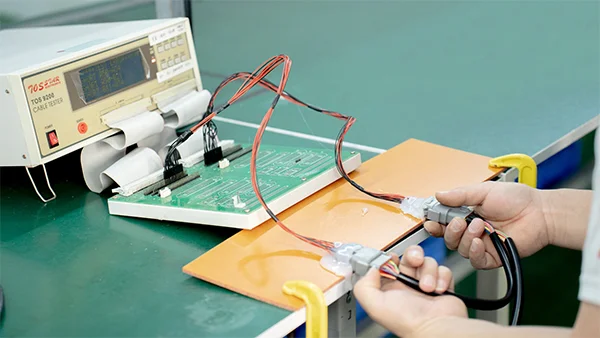

مراقبة الجودة والعمل الدقيق

في شركة QL-Custom Technology Limited، التزامنا الراسخ بمراقبة الجودة ودقة العمل جزء لا يتجزأ من كل جانب من جوانب عملياتنا. نحن متخصصون في تصنيع تجميعات الأسلاك، ومجموعات الأسلاك، ومجموعات الأسلاك، ومجموعات الكابلات التي تلتزم بأدق معايير الجودة.

يضمن فريق الخبراء المتخصصين لدينا أن كل مجموعة أسلاك، ومجموعة أسلاك، ومجموعة كبلات تلبي المواصفات الدقيقة التي حددها عملاؤنا.

وبصفتنا شركة رائدة في مجال تصنيع الأحزمة وشركة تصنيع تعاقدية عالمية، فإننا نفخر بتقديم حلول مصممة بدقة لمجموعة متنوعة من الصناعات، بما في ذلك مصنعي المعدات الأصلية (OEMs)، ومعدات الطاقة الشمسية، والإلكترونيات الاستهلاكية، وغيرها.

في إطار سعينا للتميز، نوسّع نطاق خبرتنا لتشمل الأسلاك ومجموعات الكابلات المخصصة، ونقوم بتصميم حلول الأسلاك الكهربائية وفقاً للاحتياجات المحددة لعملائنا. بدءاً من كابلات البطاريات وحتى مجموعات الأسلاك المعقدة، نصنع منتجاتنا بدقة متناهية تلبي أعلى معايير الصناعة.

بصفتنا شركة تقدم خدمات ذات قيمة مضافة، فإن التزامنا بالجودة يمتد إلى ما هو أبعد من أرضية التصنيع. تضمن قوتنا العاملة العالمية، المتمرسة في تعقيدات الأسلاك والألياف البصرية ونقل البيانات، أن منتجات شركتنا لا تلبي التوقعات فحسب، بل تتجاوزها.

سواء كانت تقنيات القيادة الآلية، أو محطات التجعيد، أو الألياف الضوئية، أو حلول بناء الصناديق، فإن نهجنا الشامل يضمن توافق كل مكون من مكوناتنا بسلاسة مع معايير الجودة الصارمة التي نلتزم بها.

اختر شركة QL-Custom Technology Limited لتلبية احتياجاتك من الأسلاك والكابلات واختبر ضمان دقة العمل والموثوقية والتميز. إن التزامنا بمعايير الجودة هو حجر الزاوية في القيمة التي نقدمها للعملاء في مختلف القطاعات، مما يجعلنا الشريك الموثوق به لجميع حلول الأسلاك الخاصة بك.

التركيز على دعم العملاء

كما أننا أحد القلائل من مصنعي تجميع الكابلات المخصصة الذين يركزون على دعم العملاء وخدماتهم. يمكن لفريق الهندسة والتصميم لدينا العمل مع فريقك الداخلي، أو يمكننا تقديم خدمات هندسية وتصميمية كاملة، مع التركيز على أقل تكلفة ممكنة وأعلى جودة إنتاج.

ستعمل شركة QL-Custom، شركة الأسلاك المسخرة، مع العملاء طوال العملية بأكملها لإنتاج التصاميم التي ترغب فيها وفقًا لمواصفاتك. سيقوم قسم الجودة بتحليل جميع المنتجات باستخدام أجهزة اختبار متقدمة قبل أن نقوم بتسليم الأجزاء بسرعة إلى وجهتك المفضلة.

نحن بالتأكيد لدينا القدرة والإمكانية لتلبية أي احتياجات قد تكون لديك تقريبًا فيما يتعلق بالقوالب البلاستيكية وأحزمة الكابلات البلاستيكية، معتمدين على قوتنا العاملة التي اختبرت على مر الزمن لضمان منتجات لن تخذلك أبدًا. نحن نتفهم التحديات والاتجاهات التي تقطع عمليات التصميم الكهربائي في جميع أنحاء العالم، ومهندسونا مستعدون دائمًا للسير معك في هذه العملية.

يوفر مورد التكامل القيّم لدينا الوقت والتكاليف للعملاء العالميين بفضل فريق هندسي فعّال يتسم بالمهارة والدقة، ويكرس جهوده دائمًا لتقديم منتجات تلبي أعلى المعايير المنصوص عليها في معايير الصناعة. نضمن لك عملية إنتاج سريعة يتم تنفيذها بدقة متناهية. هدفنا الأول والأخير هو تقديم أفضل المنتجات، وتستند قدرتنا على تقديمها على المعتقدات التالية:

- خدمة عملاء ممتازة: نحن ندرك جيداً أن العملاء الراضين هم سفراء علامتنا التجارية الأوائل.

- بيئة عمل مليئة بالطاقة الإيجابية حيث نعمل بجد في كل دقيقة مع الاستمتاع ببعض المرح على طول الطريق.

- نحن لا نستخدم سوى البائعين المعتمدين الذين ثبتت كفاءتهم في تقديم مواد خام عالية الجودة لأننا نعلم أن جودة المنتج النهائي لا تقل جودة عن جودة المواد الخام التي تدخل في صنعه.

- توصيل سريع على مستوى العالم.

تتوفر أطراف الأسلاك في طرفي الأسلاك المعزولة وغير المعزولة. ومع ذلك، يوفر العزل غطاءً واقياً. ولذلك، أعمل كموصل غير موصل. وعلاوة على ذلك، فإن نوع المشروع الذي يتم تنفيذه سيحدد ما إذا كنت بحاجة إلى أطراف معزولة أو غير معزولة.

يحمي العازل السلك من الماء والرطوبة أيضاً. كما أنه يحمي من الحرارة أو البرودة الشديدة. يتوفر عزل الأسلاك عادةً في الفينيل والنايلون والانكماش الحراري. توفر الأطراف الطرفية غير المعزولة قيمة اقتصادية أكبر بكثير مع انخفاض تكلفتها. كما أنها تستخدم عادةً عندما تكون الحماية الإضافية غير ضرورية.

عند شراء أطراف الأسلاك المختلفة، تأكد من أن عملية الشراء تفي بمعايير الصناعة ومتطلبات المشروع.

في الوقت الحاضر، تشهد صناعة تسخير أسلاك السيارات ابتكارات في المنتجات تهدف إلى تقليل الحمل. وبالتالي، يستخدم البائعون الرائدون في السوق درجات فائقة من الموصلات والعوازل والأغلفة للأسلاك والكابلات في أنظمة تسخير أسلاك السيارات.

ويساعد ذلك في تعزيز المتانة ومقاومة درجات الحرارة العالية وحماية المنتج من أي تلف. وإلى جانب ذلك، تعمل الشركة أيضاً على تطوير أحزمة الألومنيوم، حيث يتم استخدام مكونات الألومنيوم لكهربة المركبات وتقليل وزن المركبة، مما يساعد بدوره في تقليل انبعاثات الكربون.

عندما تحتاج إلى أحزمة أسلاك الكابلات للتشغيل عالي الأداء، فإن فريق العمل في Ql Custom لديه الخبرة والبصيرة لصياغة الحل المثالي. باستخدام التصميم الخاص بك، يقدم خبراء التصنيع لدينا منتجات مخصصة تتماشى مع مواصفات مشروعك مع زيادة الكفاءة والتحكم في التكلفة دائمًا.

سواءً كان هدفك النهائي هو قطع غيار الطائرات، أو المعدات الطبية، أو مكونات السيارات، أو الأجزاء البحرية، أو أي شيء مشابه، فإن أحزمة الأسلاك لدينا توفر لك الأمان وراحة البال في الأماكن عالية المخاطر. اتصل بـ Ql Custom اليوم لمعرفة كيف يمكن لمنشآتنا المتطورة وشبكة الموردين العالمية أن تلبي احتياجاتك الدقيقة.

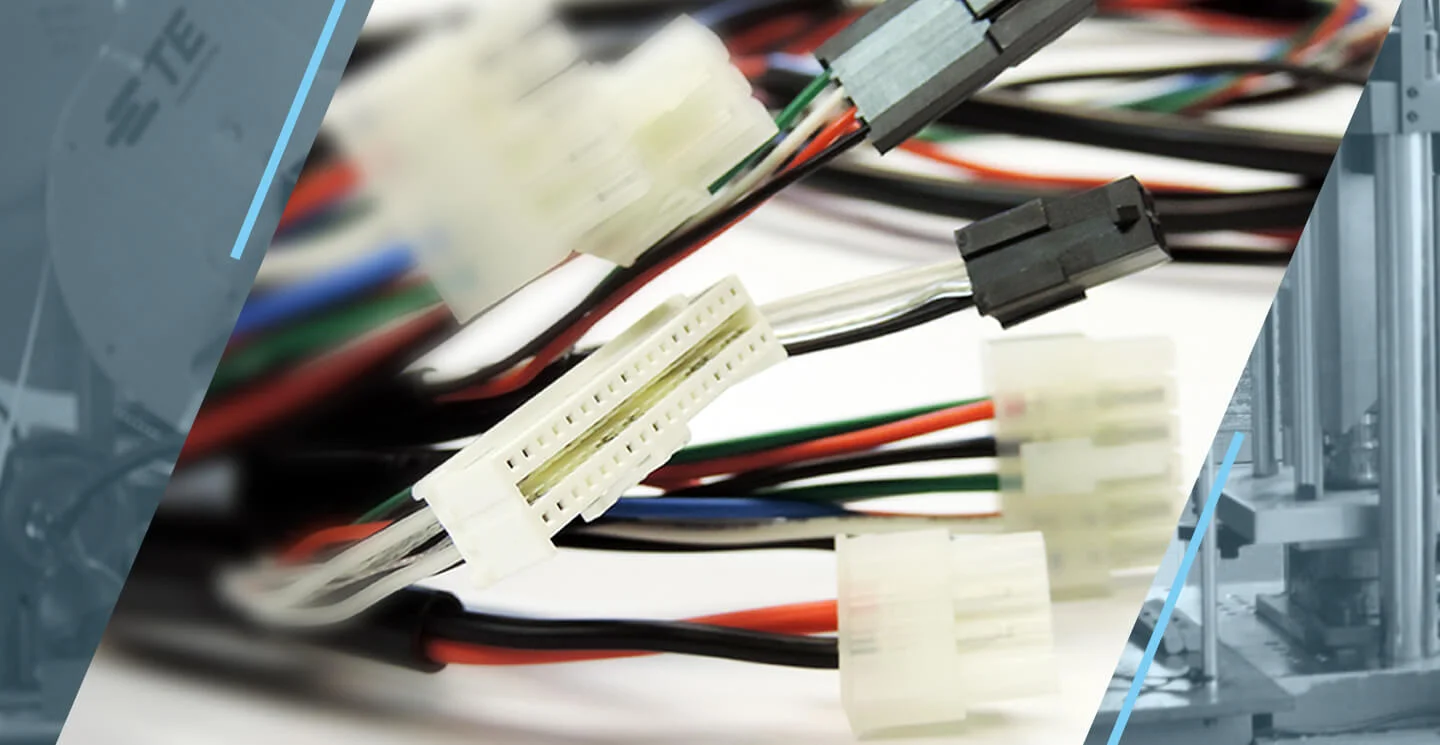

الأحزمة السلكية عبارة عن خليط من الأسلاك التي يتم تجميعها معًا لتشكيل حزام سلكي. وتتراوح الأحزمة السلكية في تعقيدها من بضعة أسلاك فردية تنتقل من نقطة إلى نقطة إلى مئات الأسلاك الفردية والكابلات متعددة الموصلات والأسلاك الملحومة التي تشكل جميعها أحزمة سلكية معقدة تستخدم لنقل الطاقة وجميع أنواع البيانات.

تصميمات أحزمة الأسلاك قابلة للتخصيص بدرجة كبيرة، حيث يتم تصميم الأحزمة عادةً لتناسب تطبيقات محددة. قد تحتاج إلى إخفائها خلف الجدران، أو ملاءمتها داخل الصناديق الكهربائية، أو التوافق مع قيود المساحة الأخرى. يجب أخذ قياسات دقيقة للبيئة والطلب على الطاقة والأطوال أثناء التصميم لمنع حدوث أخطاء مكلفة وضمان السلامة والأداء الوظيفي المناسب للمنتج النهائي.

يجب أن يتناسب الحزام بشكل أنيق مع المساحة المخصصة له. على سبيل المثال، تكون الأحزمة في السيارات مضغوطة للغاية لضمان ملاءمتها داخل الصناديق الكهربائية الصغيرة الموجودة داخل السيارات. يجب أخذ حجم الغلاف الخارجي الواقي في الاعتبار.

غالبًا ما تتطلب أحزمة الأسلاك تصميمًا معقدًا للهيكل مع التثبيت الميكانيكي والموصلات المصبوبة بشكل مفرط والحلقات وتخفيف الضغط واللحامات فوق الصوتية. تعد أنواع المحطات الطرفية وكيفية ملاءمتها لنصف قطر السلك من القرارات الحاسمة أثناء التصميم.

الأسئلة الشائعة

س1: ما هي مجموعة الأسلاك، وكيف تختلف عن مجموعة الأسلاك أو مجموعة الكابلات؟

مجموعة الأسلاك، والمعروفة أيضًا باسم مجموعة الأسلاك أو مجموعة الكابلات، هي مجموعة من الأسلاك أو الكابلات المربوطة معًا بأغطية واقية. في حين أن المصطلحين غالباً ما يستخدمان بالتبادل، قد توجد اختلافات دقيقة. تشير تجميعات الأسلاك بشكل عام إلى التجميع المنظم للأسلاك، وعادةً ما تكون محاطة بأغلفة واقية، ومصممة لسهولة التنفيذ في المعدات والأنظمة.

س2: ما هي الاستخدامات الأساسية لمجموعات الأسلاك والكابلات؟

تتنوع استخدامات أحزمة الأسلاك وتجميعات الكابلات في صناعات متنوعة مثل السيارات والإلكترونيات الاستهلاكية والاتصالات السلكية واللاسلكية والمعدات الطبية والطاقة النظيفة وغيرها. فهي تلعب دوراً حاسماً في تنظيم الأسلاك الكهربائية وحمايتها، مما يضمن اتصالاً موثوقاً ووظائف فعالة للنظام.

س3: ما الذي يميز شركة QL-Custom Technology Limited كشركة مصنعة لأحزمة الأسلاك؟

شركة QL-Custom هي شركة تصنيع تعاقدية عالمية متخصصة في تجميعات الأسلاك وحلول الكابلات المخصصة. تمتد خبرتنا إلى مختلف القطاعات، بما في ذلك مصنعي المعدات الأصلية (OEMs)، ومعدات الطاقة الشمسية، والإلكترونيات الاستهلاكية، والقيادة الآلية. نحن نعطي الأولوية للدقة والموثوقية والالتزام بأعلى معايير الجودة.

س4: هل يمكن لشركة QL-Custom توفير حلول تسخير الأسلاك المخصصة المصممة خصيصًا لتلبية احتياجات صناعية محددة؟

نعم، تتخصص شركة QL-Custom في توفير أحزمة الأسلاك وتجميعات الكابلات لتلبية المتطلبات الفريدة لمختلف الصناعات. سواءً كانت تطبيقات السيارات أو تركيبات معدات الطاقة الشمسية أو البنية التحتية للاتصالات، فإن حلولنا مصممة لتقديم الأداء الأمثل.

السؤال 5: ما هي مزايا استخدام الأسلاك في تقنيات القيادة الآلية؟

تضمن مجموعات الأسلاك في تقنيات القيادة الآلية نقل البيانات بدقة وموثوقية. ويدعم استخدام أطراف التجعيد وتجميعات الكابلات المخصصة الاحتياجات الكهربائية المعقدة للمركبات الآلية، مما يساهم في تكاملها ووظائفها بسلاسة.